Multistreaming high-precision rotary ring type flow sensor and working method thereof

A flow sensor, high-precision technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, volume/mass flow generated by mechanical effects, etc., can solve ultrasonic flowmeter transmission and reception failures, mechanical flowmeter failure , unable to reach the receiver and other problems, to achieve uniform and stable force distribution, eliminate measurement errors, and improve flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

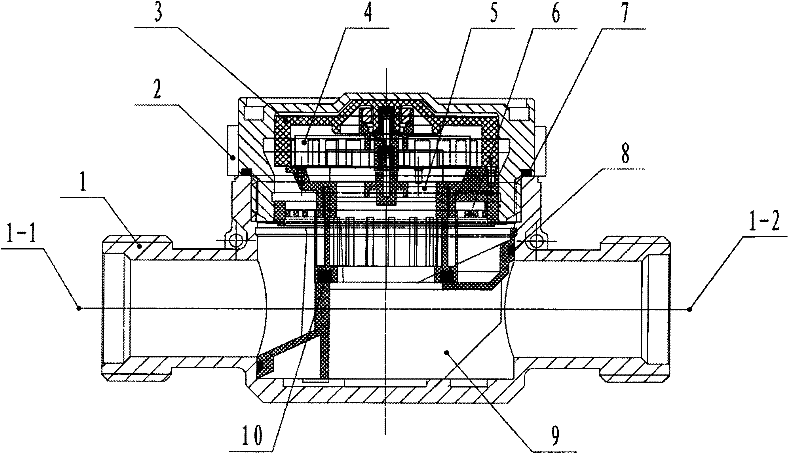

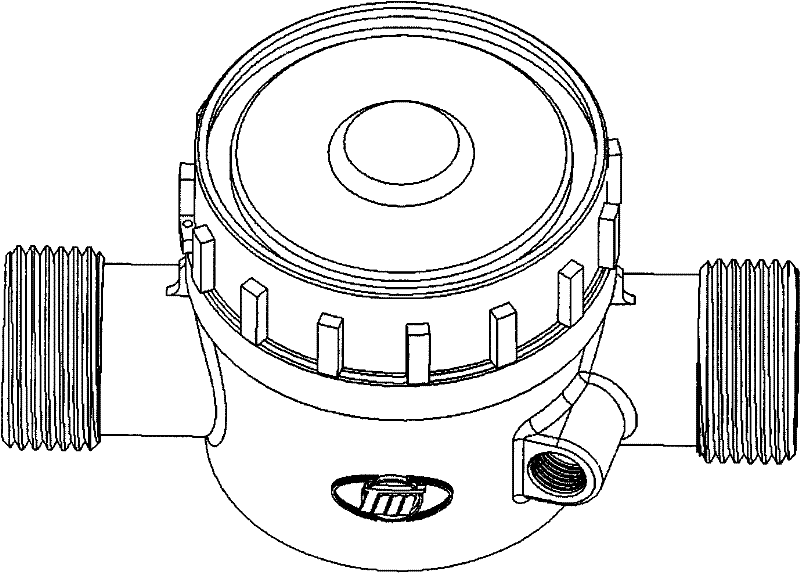

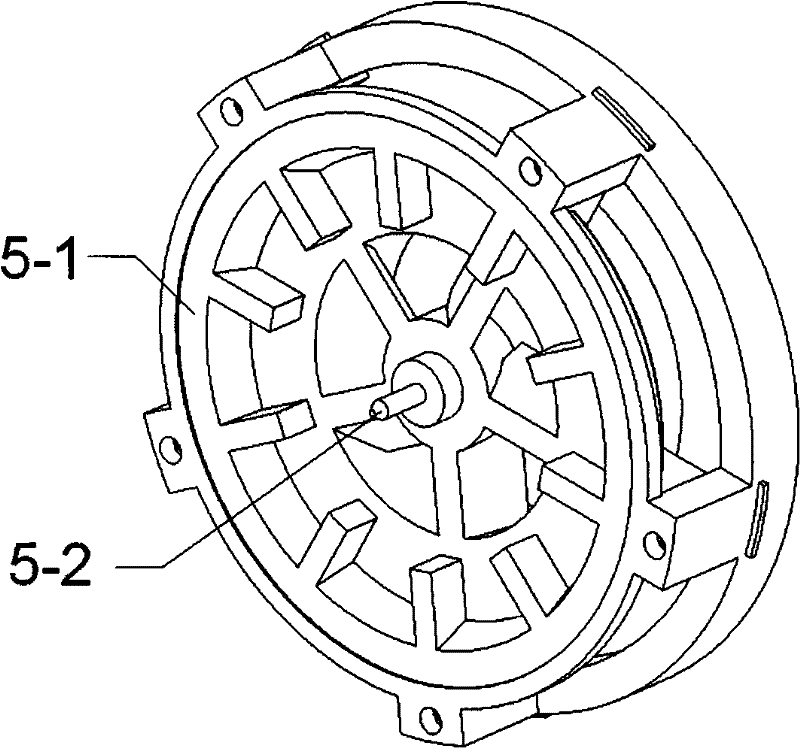

[0045] Embodiment 1: a kind of multi-beam high-precision rotor type flow sensor (see figure 1 , figure 2 , Figure 16 ), characterized in that it includes a flowmeter housing 1, a flowmeter upper cover 2, an upper impeller casing assembly 3, an impeller assembly 4, a lower impeller casing assembly 5, a filter screen 6, a flow guide assembly, an outer metering chamber 11 and an inner metering chamber Chamber 12; the flow guide assembly is connected to the bottom of the flowmeter housing 1; the guide assembly has a guide slope and a central cylindrical water outlet hole; the filter screen 6 is installed on the guide assembly; the lower impeller shell assembly 5 Installed on the filter screen 6; the upper impeller shell assembly 3 is installed on the lower impeller shell assembly 5; the lower cylindrical ring of the upper impeller shell assembly 3 has 20 wedge-shaped water inlets distributed at unequal intervals; the impeller assembly 4 Installed between the upper impeller she...

Embodiment 2

[0061] Embodiment 2: A multi-beam high-precision rotor-type flow sensor is characterized in that it includes a flowmeter housing 1, a flowmeter upper cover 2, an upper impeller housing assembly 3, an impeller assembly 4, a lower impeller housing assembly 5, a filter Net 6, diversion assembly, outer metering chamber 11 and inner metering chamber 12; the bottom of the flowmeter housing 1 is connected to the diversion assembly; the diversion assembly has a diversion slope and a central cylindrical outlet hole; the filter screen 6 Installed on the guide assembly; the lower impeller shell assembly 5 is installed on the filter screen 6; the upper impeller shell assembly 3 is installed on the lower impeller shell assembly 5; the lower cylindrical ring of the upper impeller shell assembly 3 has 20 Wedge-shaped water inlets distributed at unequal intervals; the impeller assembly 4 is installed between the upper impeller shell assembly 3 and the lower impeller shell assembly 5; the flowm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com