Lifting appliance for iron core winder body

A technology of iron core and body, applied in the field of rolling iron core body spreader, can solve the problems of no safety guarantee, reluctance, difficulty, etc., and achieve the effect of simple structure, convenient use and stable footing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

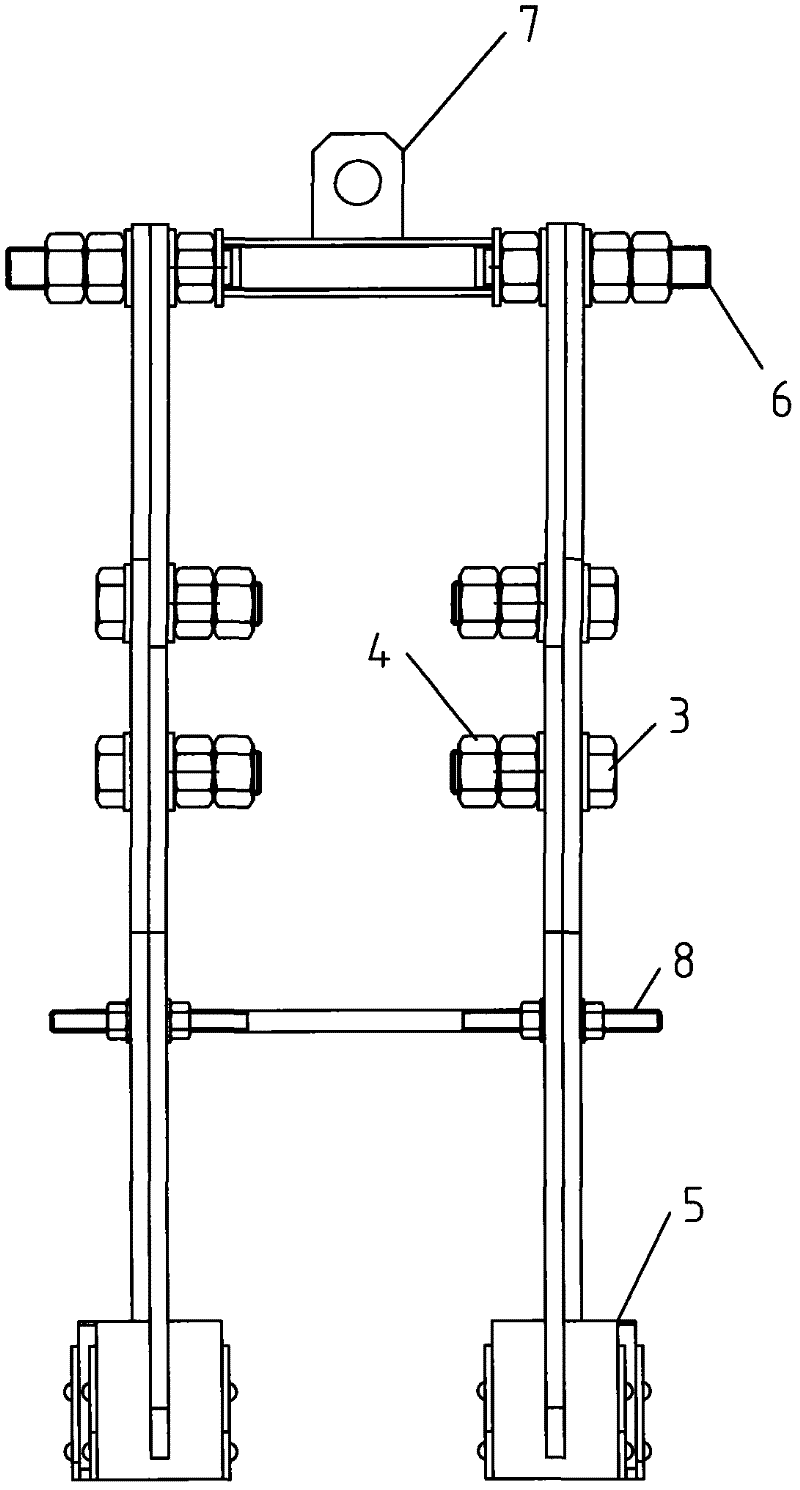

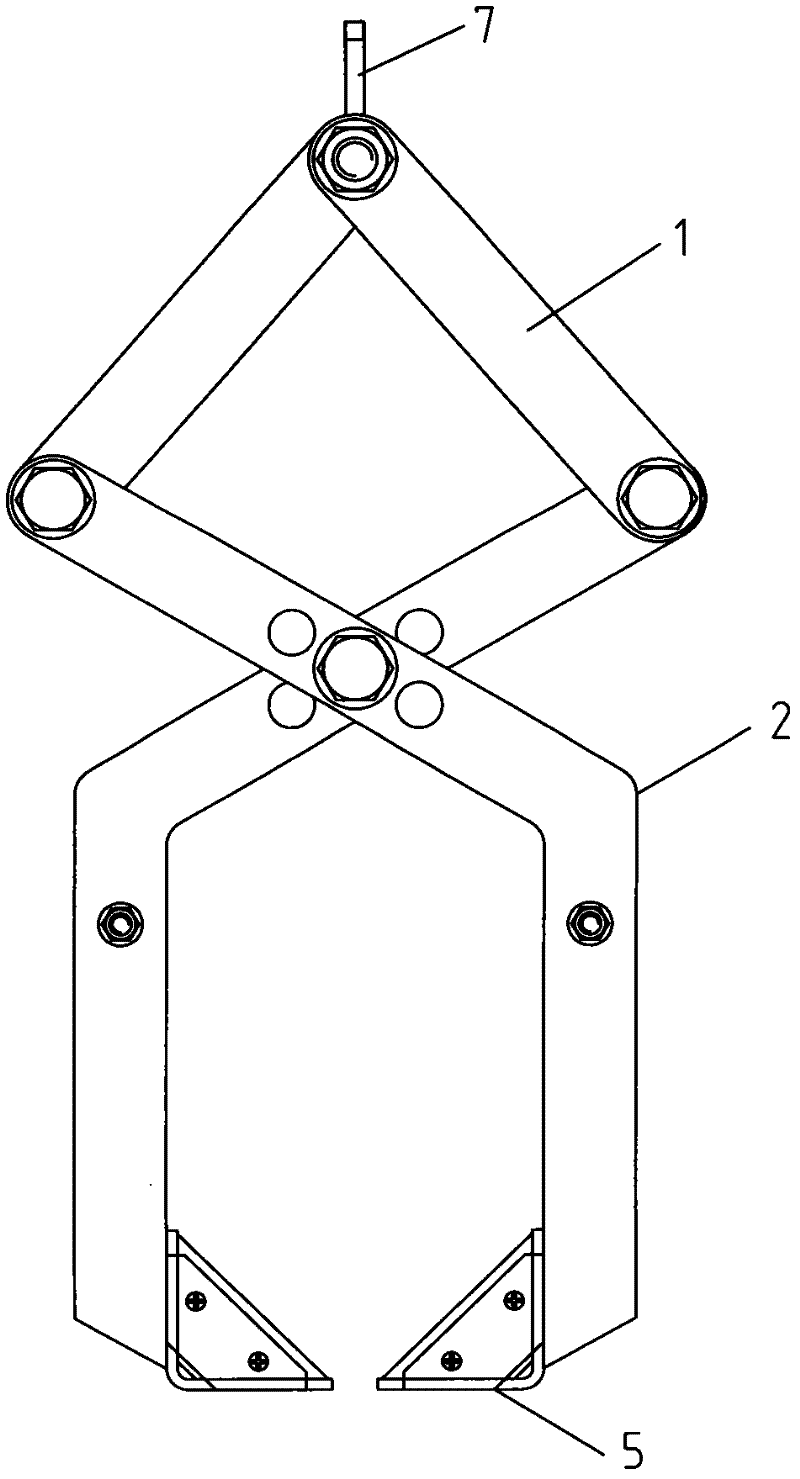

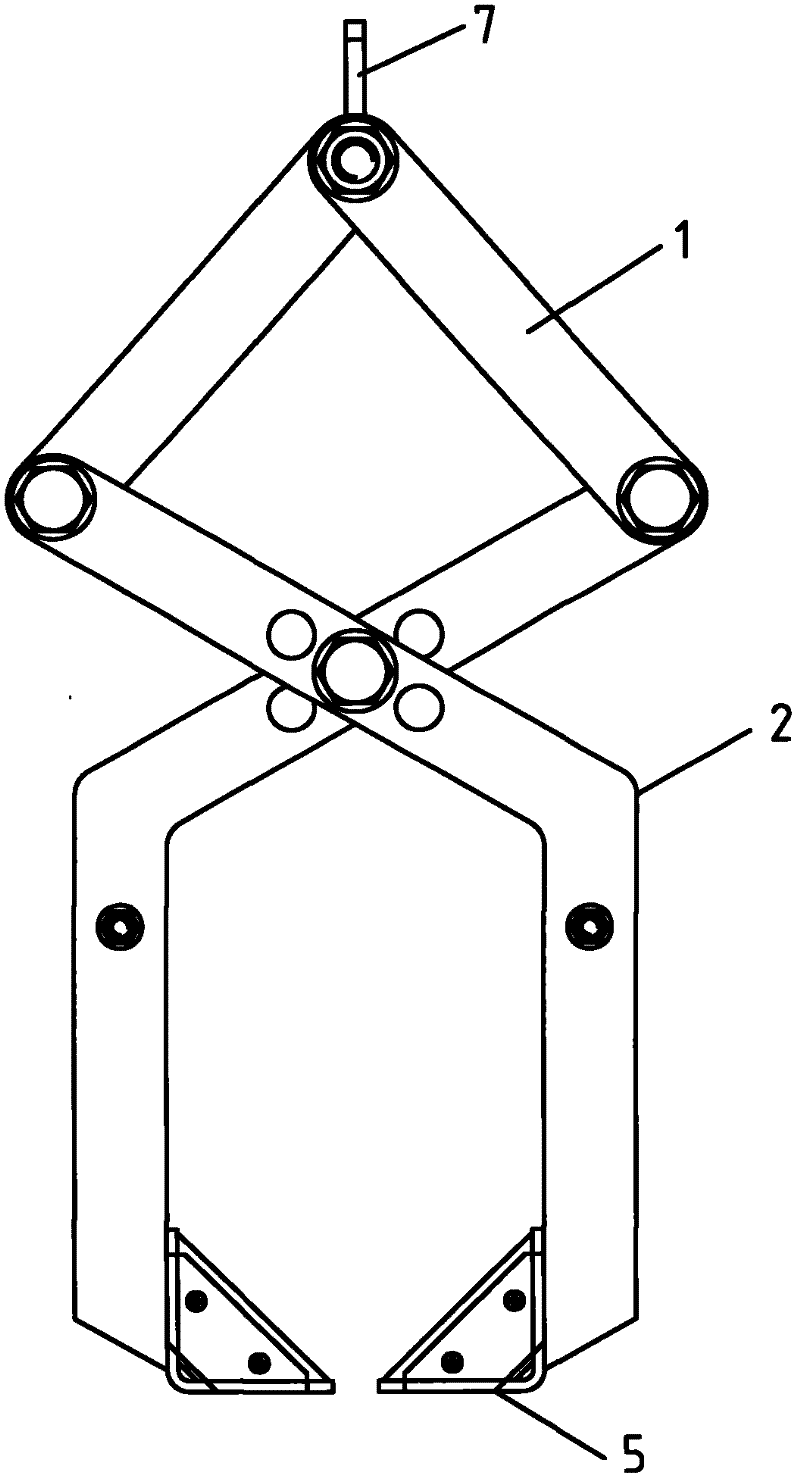

[0011] combine figure 1 , 2 A coiled iron core body hanger shown is composed of two sets of suspension ring assemblies with the same structure, and the suspension ring assembly has two connecting plates 1, and the two connecting plates 1 form a scissors structure, and the two connecting plates 1 The other end of the plate 1 is respectively connected with an L-shaped hook steel 2, and the two hook steels 2 are arranged crosswise, and the intersecting parts are connected by bolts 3 and nuts 4, and the two hook steels 2 A wooden spacer 5 is relatively installed on the other end respectively. In order to make the device stay stable, the wooden spacer 5 adopts a triangular structure, and the two groups of suspension ring assemblies are connected by the following two points: at the intersecting part of the scissors structure They are connected by large bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com