Hydraulic drive unit for injection moulding machine

A technology of injection molding machine and driving unit, applied in the direction of fluid pressure actuating device, etc., can solve the problem of large space position of the displacement measurement system, and achieve the effect of saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

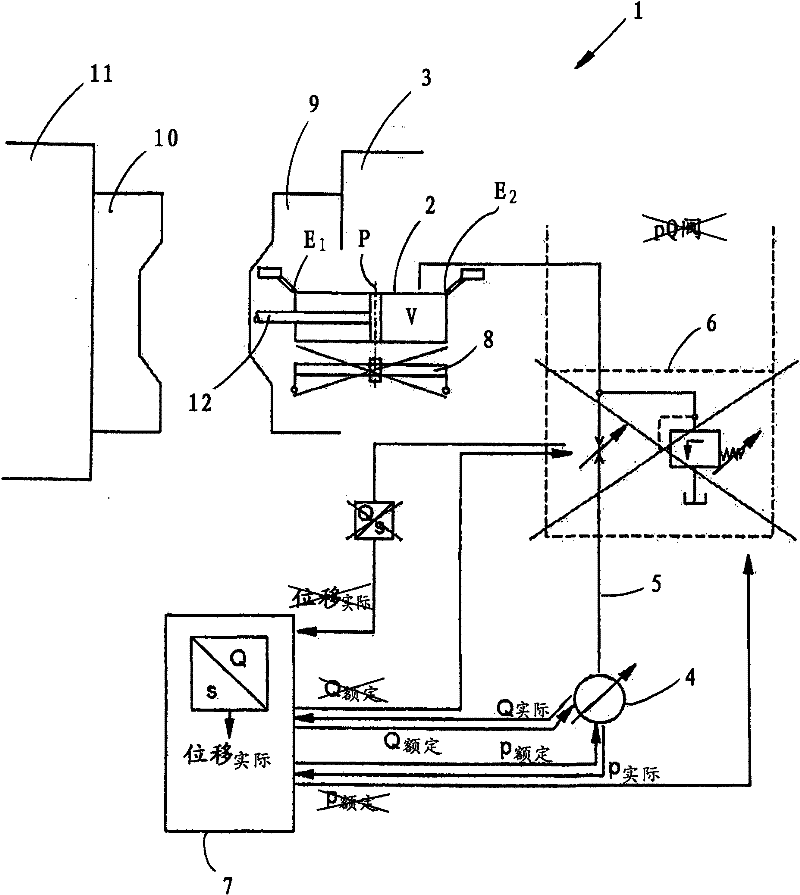

[0025] It should be noted that the following functional descriptions are all aimed at the core-pulling mechanism of the injection molding machine, which is only used as an example here, because general functions can be used for all movements of the hydraulic transmission components of the injection molding machine.

[0026] Generally speaking, the hydraulic drive unit 1 can move, for example, the core-pulling mechanism in the area of the fixed mold clamping plate 3 through the piston of the hydraulic cylinder 2 . The mold half 9 is arranged on the fixed mold jaw 3 , where a second mold half 10 can be moved towards the mold half 9 via the movable mold jaw 11 .

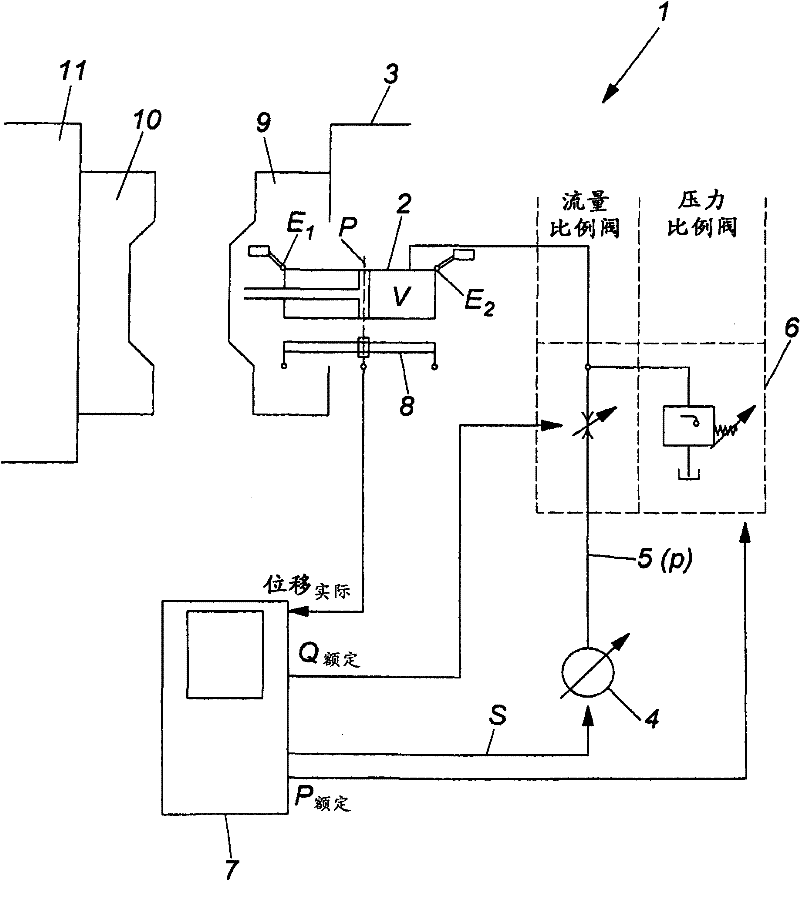

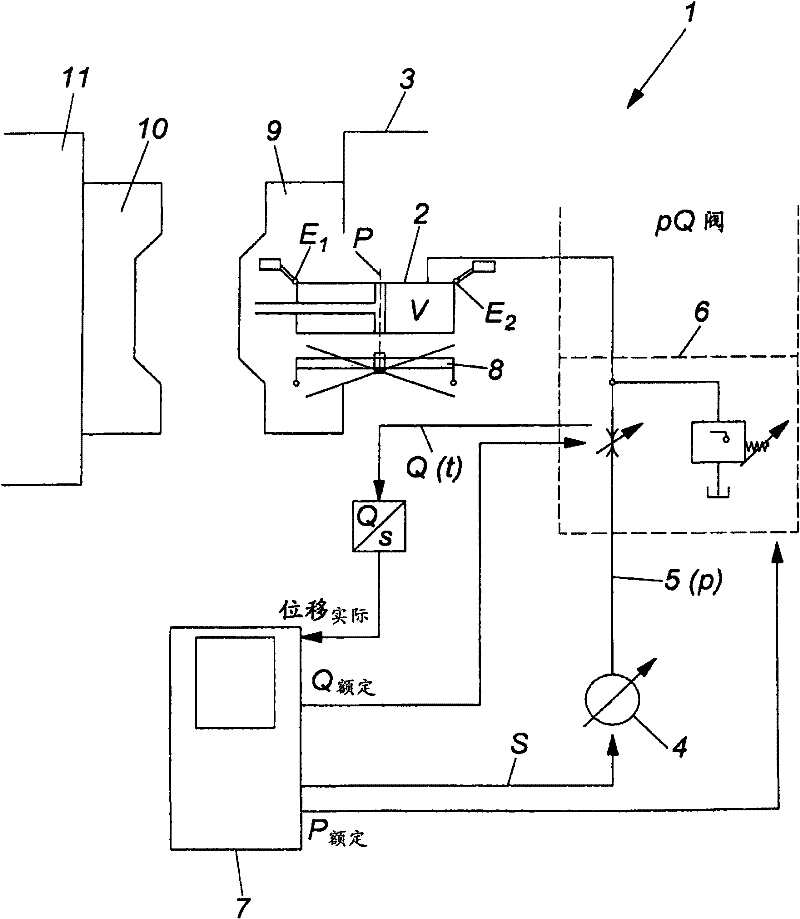

[0027] In a standard injection molding machine, the pressure and flow of the moving device (hydraulic cylinder 2 and piston) of the injection molding machine components are controlled by controlling the pump. In special circumstances (such as the attached figure 1 shown) using a pressure proportional valve. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com