Multi-axis screw machines for devolatilization of polymer melts

A devolatilization, polymer technology, applied in the field of multi-axis screw machines, can solve the problem of high technical expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

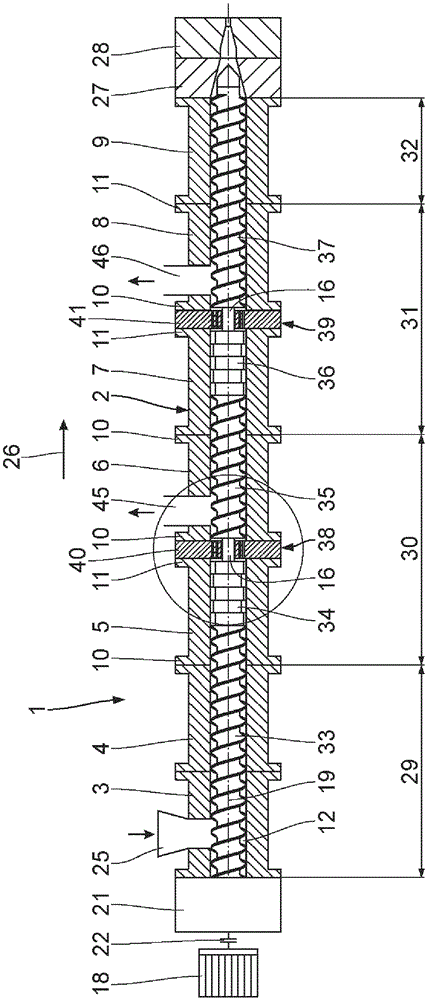

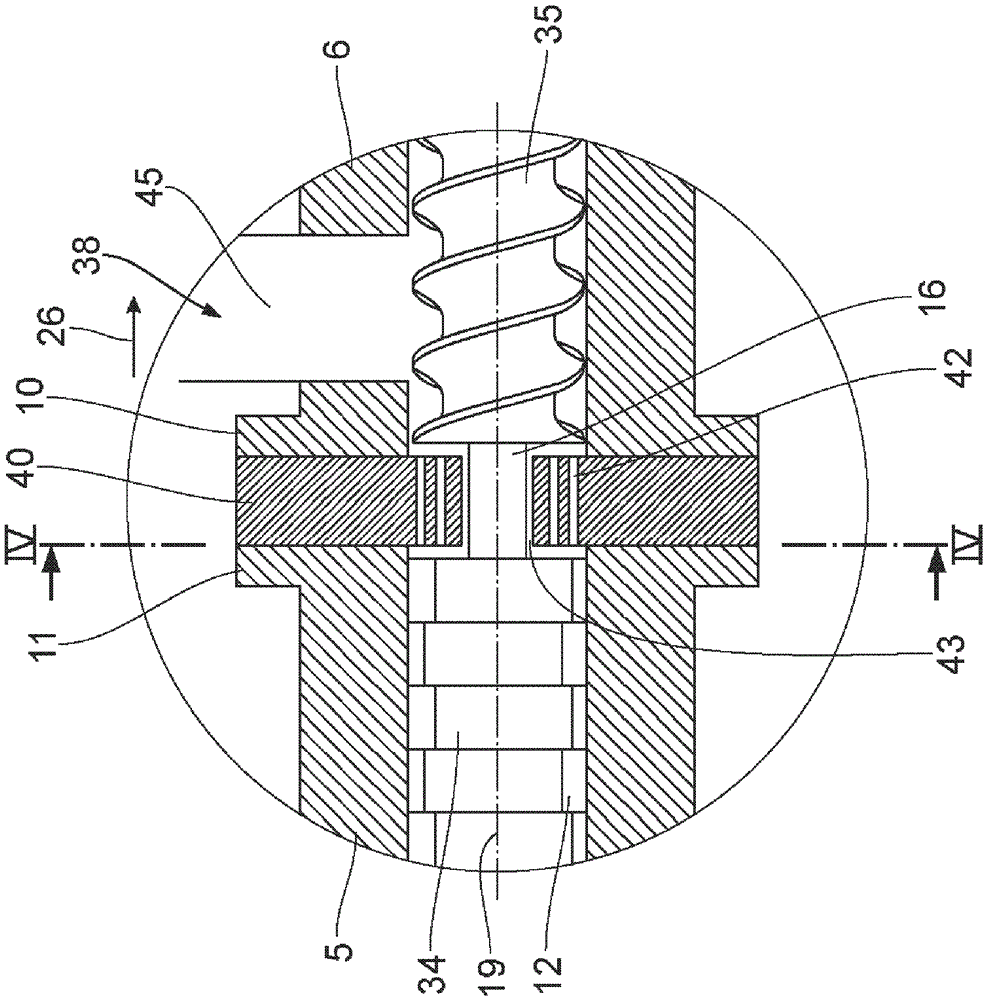

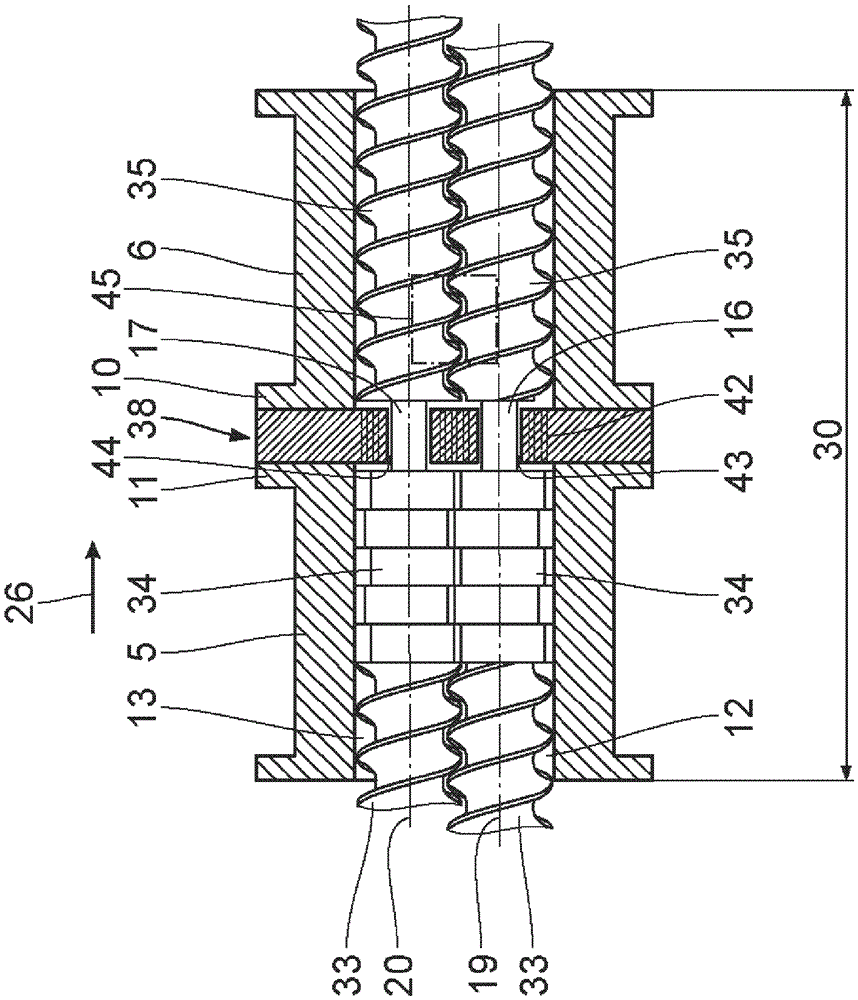

[0029] Refer below Figure 1~4 A first embodiment of the present invention is described. A twin-shaft screw machine 1 has a housing 2 which comprises a plurality of housing parts 3 - 9 arranged behind one another, which are referred to as housing segments. The housing segments 3 - 9 each have a flange 10 , 11 at the end, by means of which the housing parts 3 - 9 are connected to one another to form the housing 2 .

[0030] In the housing 2 are formed two housing holes 12 , 13 parallel to each other and penetrating each other, the housing holes having a horizontal "8" shape in cross-section. In the penetration region of the housing bores 12 , 13 , the housing parts 3 - 9 have so-called spandrels 14 , 15 .

[0031]Arranged concentrically in the housing bores 12 , 13 are two shafts 16 , 17 which can be rotatably driven by a drive motor 18 about relative axes of rotation 19 , 20 . A transfer gear 21 is arranged between the shafts 16 , 17 and the drive motor 18 , and a clutch 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com