Flapping wing driving mechanism of two-level parallel gear reduction

A technology of parallel gears and drive mechanisms, applied in the field of flapping wing drive mechanisms, can solve the problems of difficulty in applying miniature flapping wing aircraft, short service life, complex structure, etc., achieve good space utilization, reduce wear and tear, and high positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

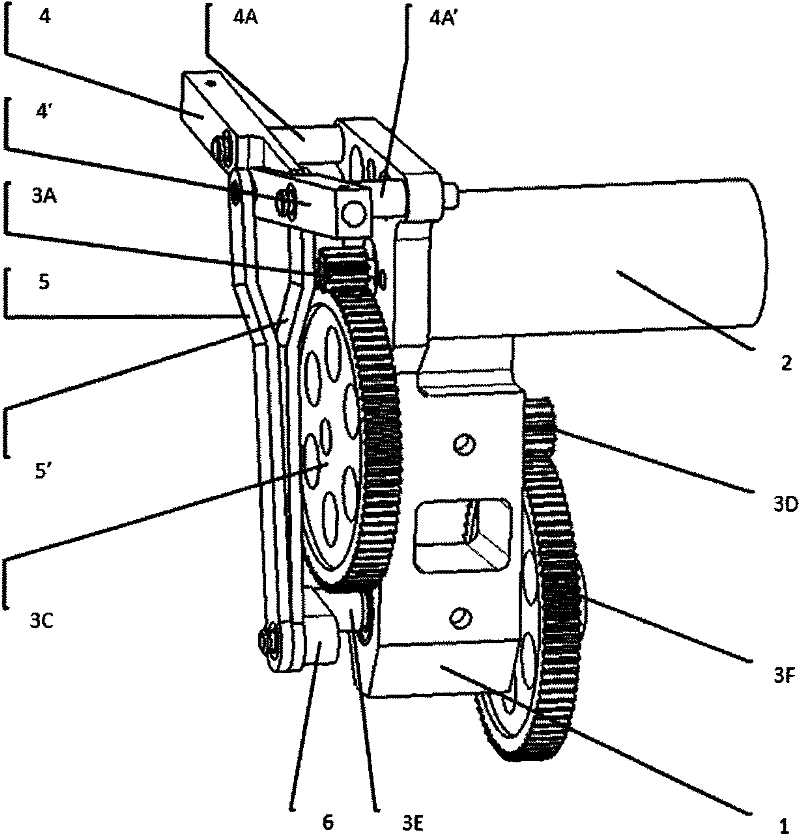

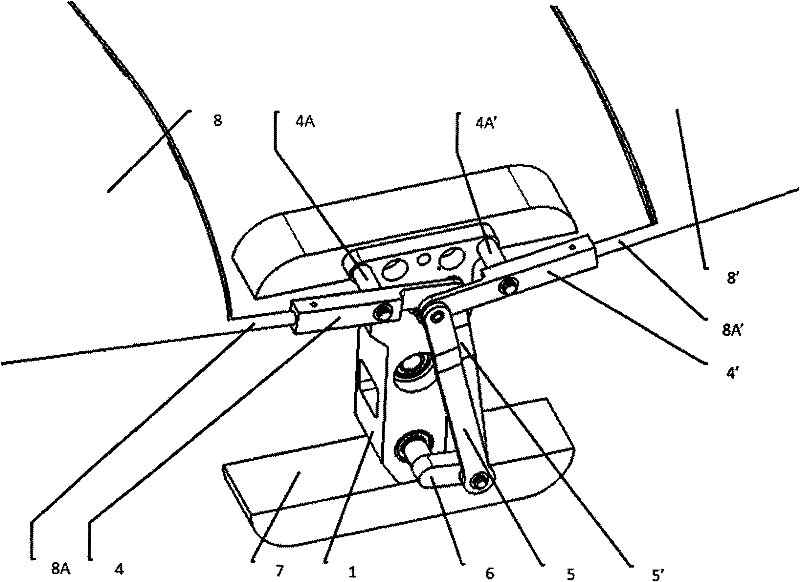

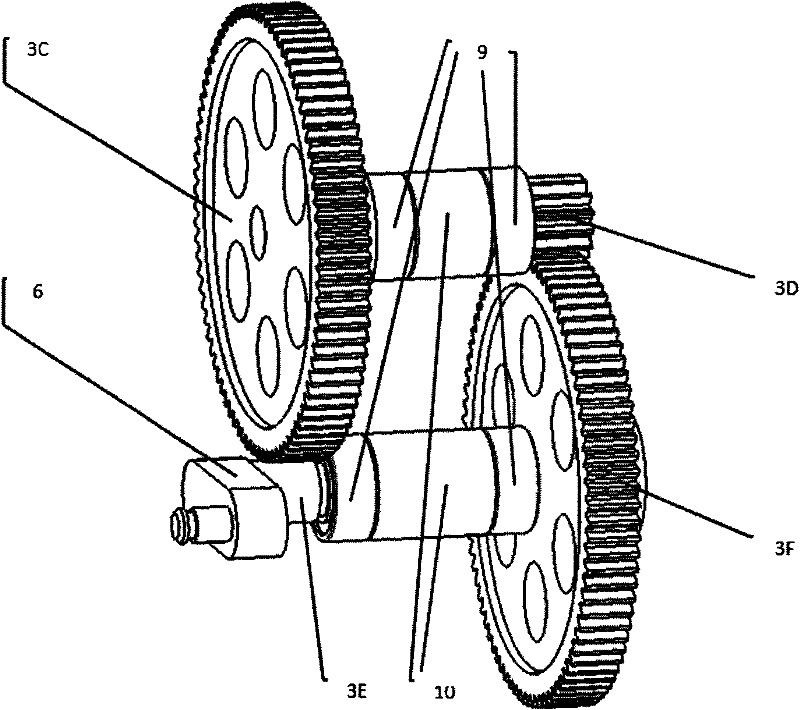

[0025] The two-stage parallel gear reduction flapping wing drive mechanism of the present invention includes a frame, a motor, a two-stage parallel gear reducer and a four-bar linkage mechanism.

[0026] Frame 1 is a left-right symmetrical overall structure, and the bottom surface and the front upper part have fixing holes with axes perpendicular to the surface respectively, and are connected with the flapping-wing aircraft fuselage frame 7 by said fixing holes, and the connection mode is a pin connection or a threaded connection. The frame 1 has a motor 2 mounting hole 1A, a transmission shaft hole 1B and a crank shaft hole 1C in the front and rear directions. There are two symmetrical rocker shaft holes 1D and 1D' above the crank shaft hole 1C, and their axes are parallel to the axes of the aforementioned three holes. In addition, the frame 1 also ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com