Control method of decarburization of continuously cast bloom for spring steel wire rods

A control method and continuous casting slab technology, which is applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of spring failure, time-consuming and labor-intensive efficiency, fracture, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A further detailed description is given below:

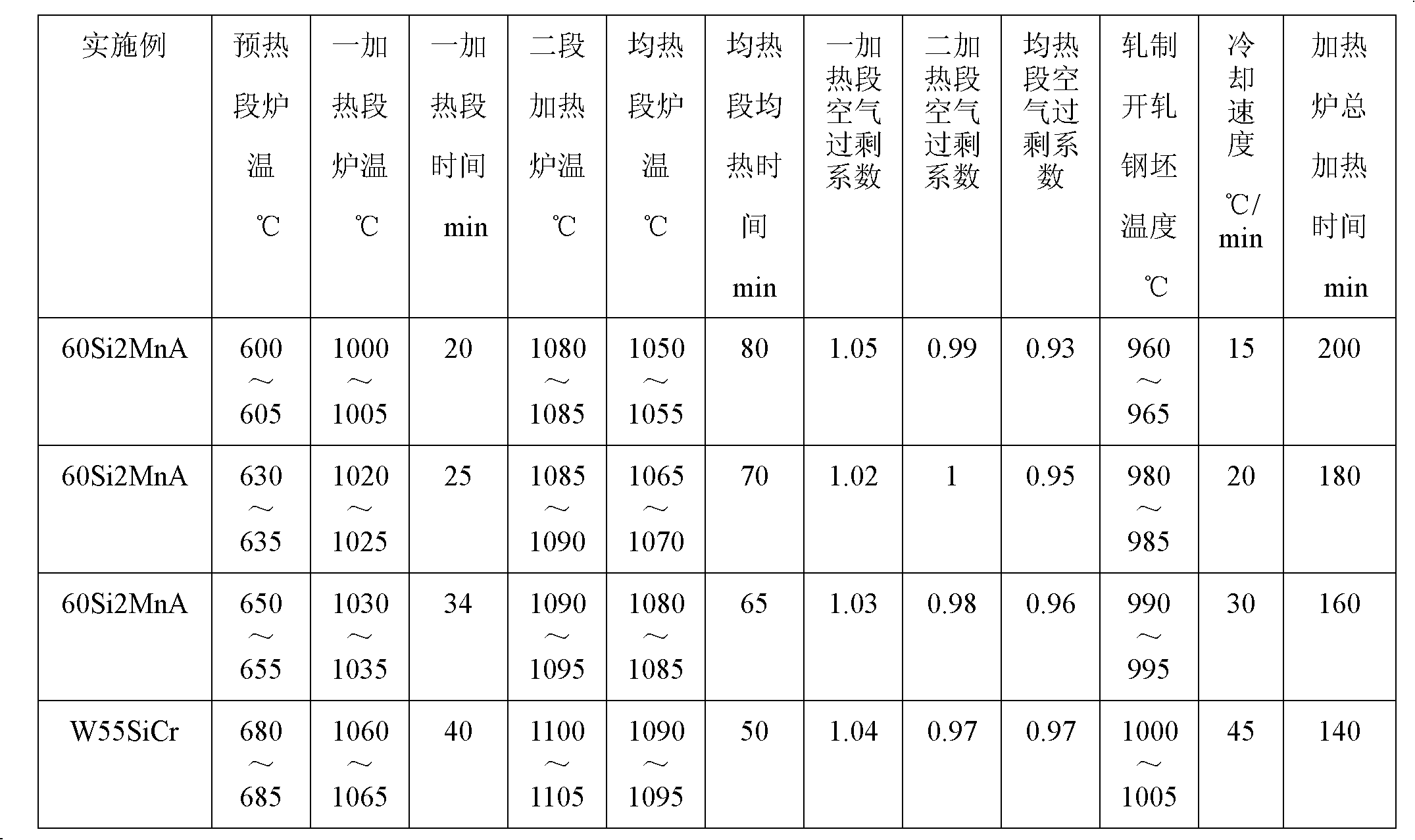

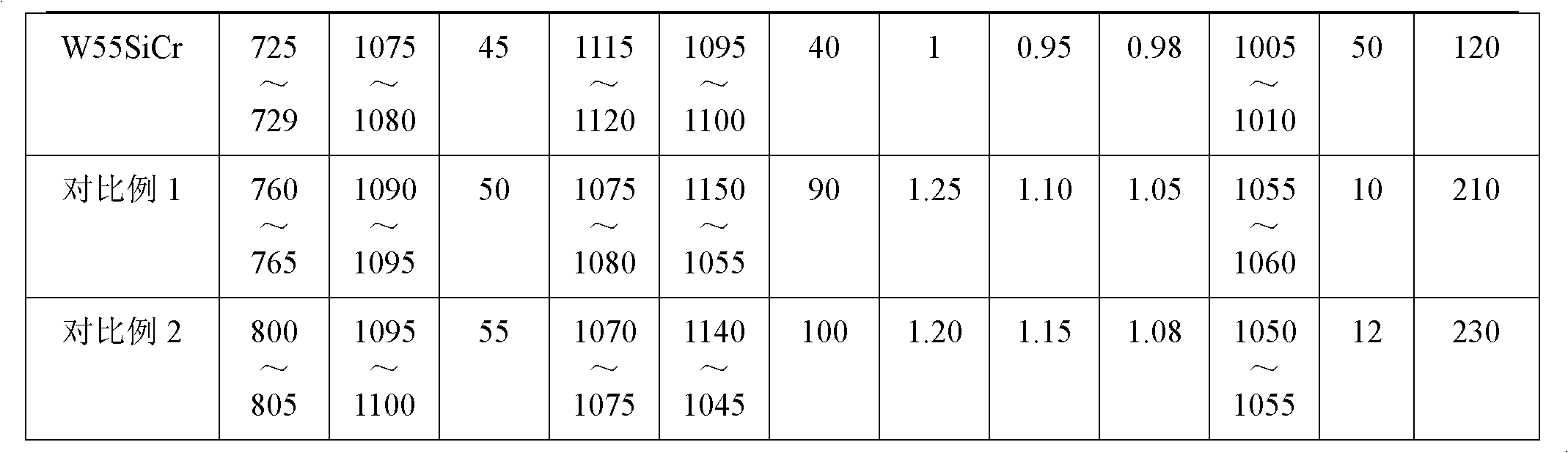

[0021] The embodiment is carried out according to the following process steps, and is used in the production of spring steel wire rods 60Si2MnA, W55SiCr for automobiles and spring steel wire rods for continuous casting. The main process parameters are shown in Table 1, and the experimental results are shown in Table 2.

[0022] Each embodiment follows the control method, its steps:

[0023] 1) Carry out smelting, continuous casting into slabs, and clean up the surface of the continuous casting slabs;

[0024] 2) Heating the continuous casting slab in sections under a reducing atmosphere, and the heating time from the beginning of preheating to the furnace is controlled at 120 to 200 minutes;

[0025] Temperature control at each stage:

[0026] The furnace temperature in the preheating section is controlled at ≤730°C;

[0027] The furnace temperature in the first heating section is controlled at 1000-1080°C, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com