Spinning shell fabric with jacquard weave effect

A technology of textile fabrics and blended yarns, which is applied in the field of textile fabrics to achieve the effects of simple weaving process, good moisture absorption and perspiration function, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

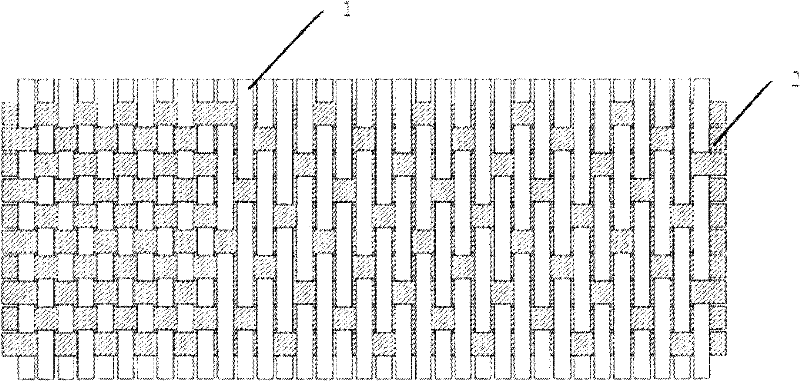

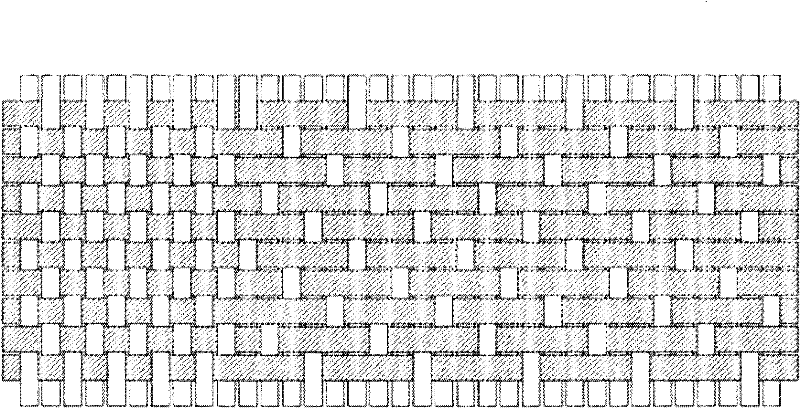

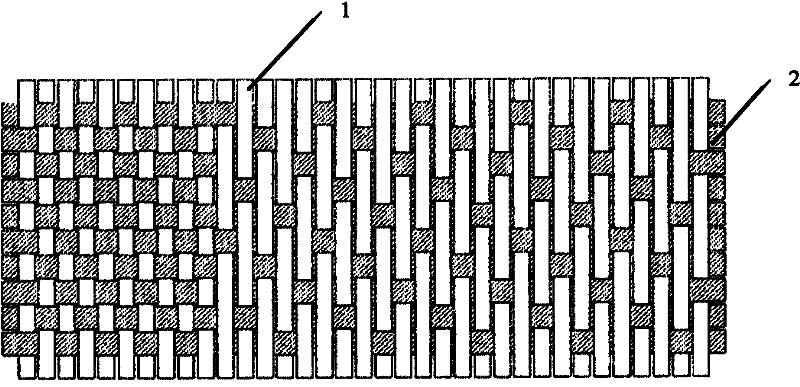

[0018] The purpose of the present invention is to provide a striped jacquard-style textile fabric, which is interwoven into plain weave units and satin weave units by warp and weft threads, and the plain weave units and satin weave units are arranged alternately horizontally or vertically, so that the textile The finished fabric forms a jacquard effect with alternate vertical or horizontal stripes on the whole.

[0019] like figure 1 and figure 2 As shown, 1 in the figure represents the warp, and 2 represents the weft, wherein the warp and weft with the same stripes correspond to the corresponding warp and weft respectively, and will not be mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com