Lamp structure

A technology for lamps and lamp panels, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of wire falling off, not easy to fix, and LED lamps cannot operate normally, so as to avoid short circuit and simplify assembly The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

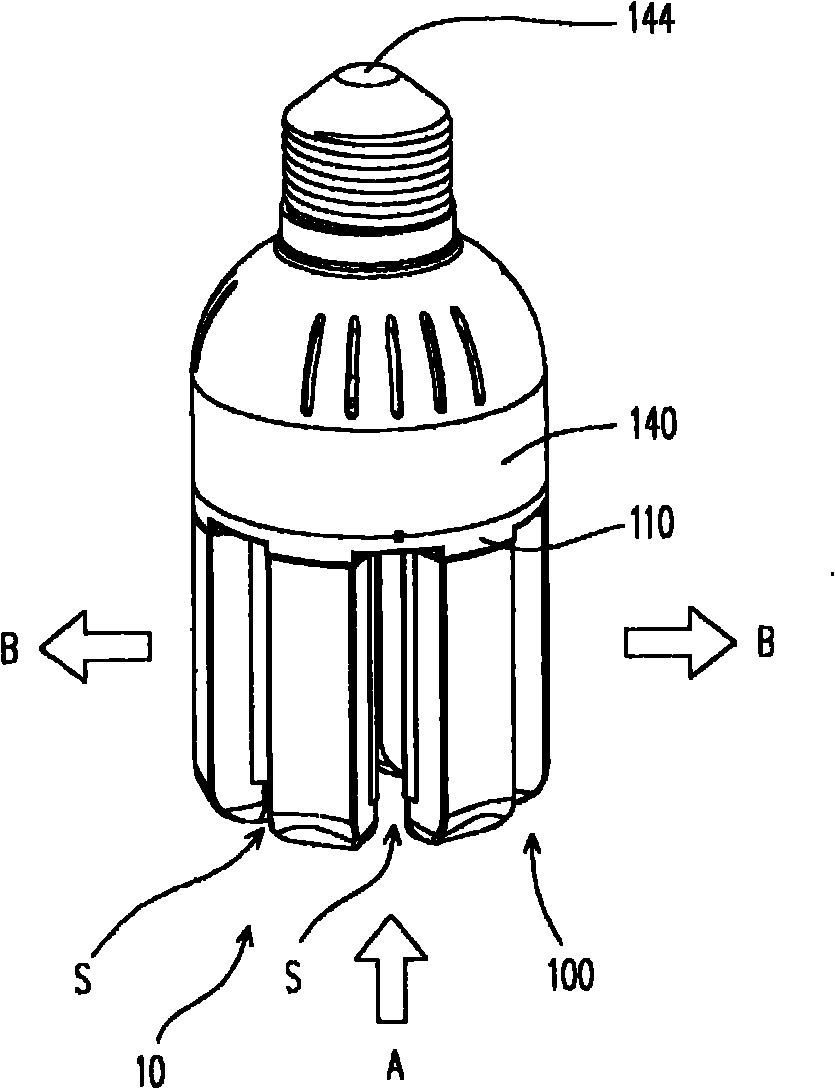

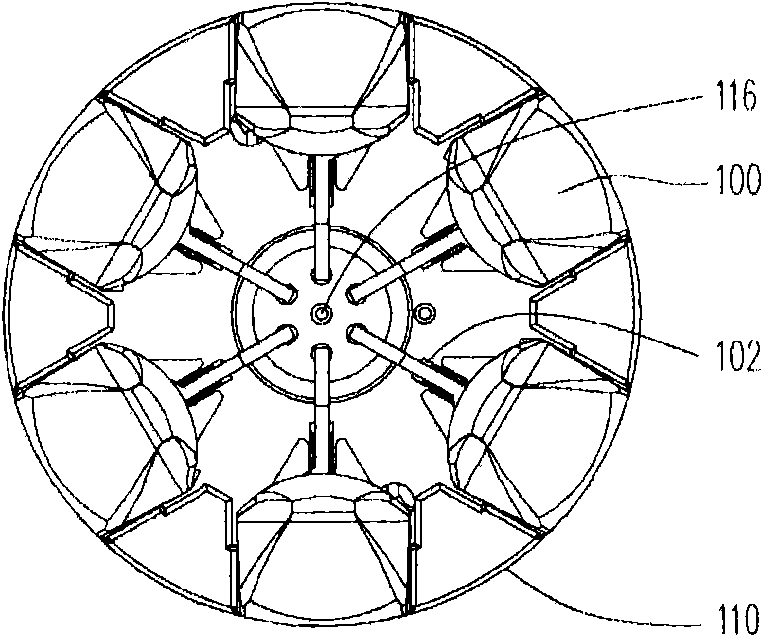

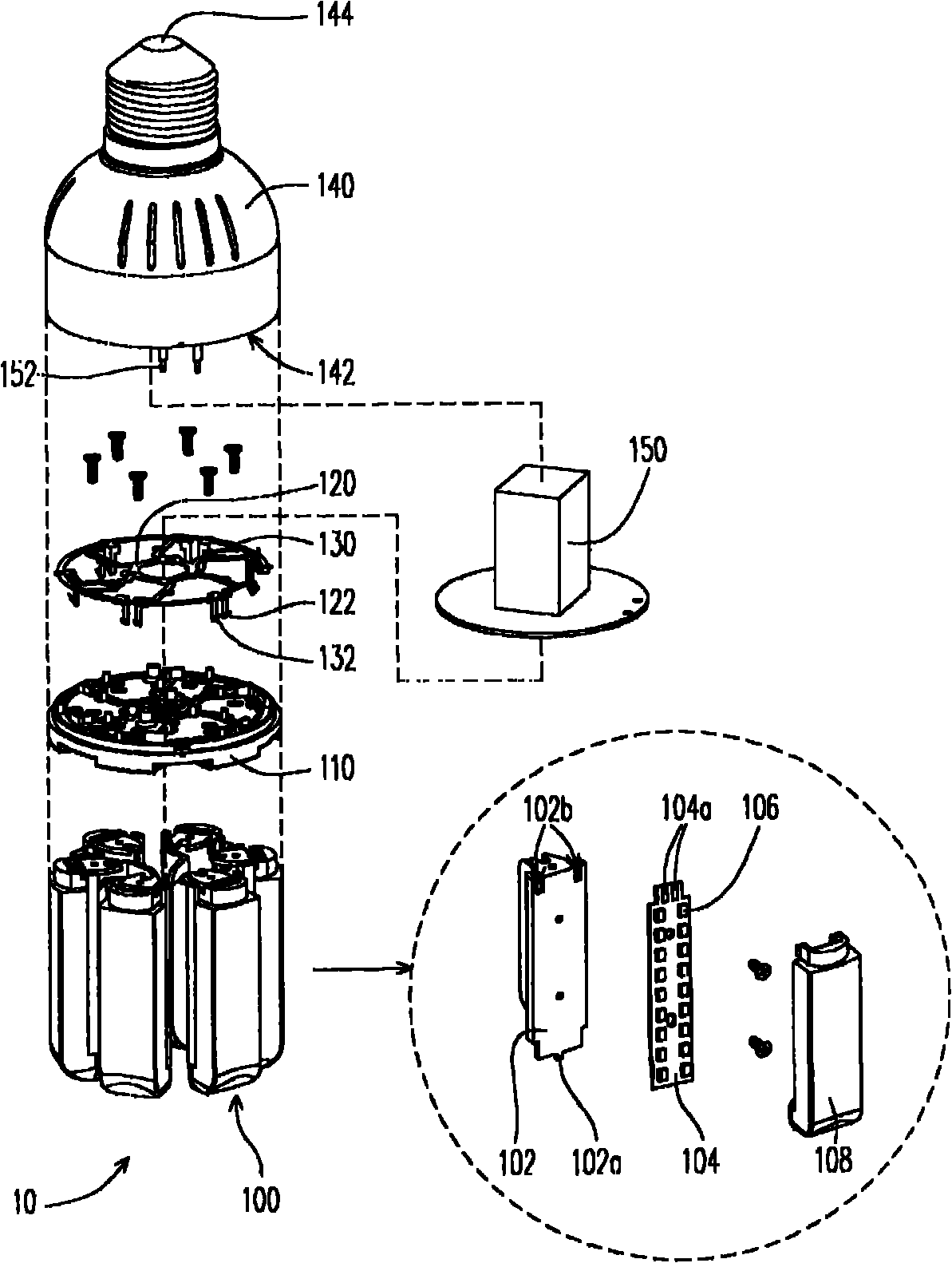

[0025] figure 1 It is an assembly diagram of a lamp structure according to an embodiment of the present invention. figure 2 It is a front view of the light emitting unit of the lamp structure according to an embodiment of the present invention. image 3 It is an exploded schematic diagram of the structure of a lamp according to an embodiment of the present invention.

[0026] Please refer to figure 1 , figure 2 and image 3 , the lamp structure 10 of the present invention is a lamp structure with lateral light output, wherein a plurality of light emitting units 100 are fixed on an insulating base 110 . Such as figure 2 As shown, the number of light-emitting units 100 is, for example, 6 or more, and each light-emitting unit 100 can be independently snapped on different directions of the insulating base 110 and emit light in different directions. Also because these light-emitting units 100 are arranged around the center of the insulating base 110, and a plurality of hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com