Reeling device

A technology of coiling device and winding mechanism, which is applied in the direction of sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve the problems of inconsistent coating spacing of active materials and reduced productivity, and achieve stable positional relationship, Suppress production costs and seek the effect of simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]An embodiment will be described below with reference to the drawings. First, the structure of the lithium ion battery element obtained by the winding device of this embodiment is demonstrated.

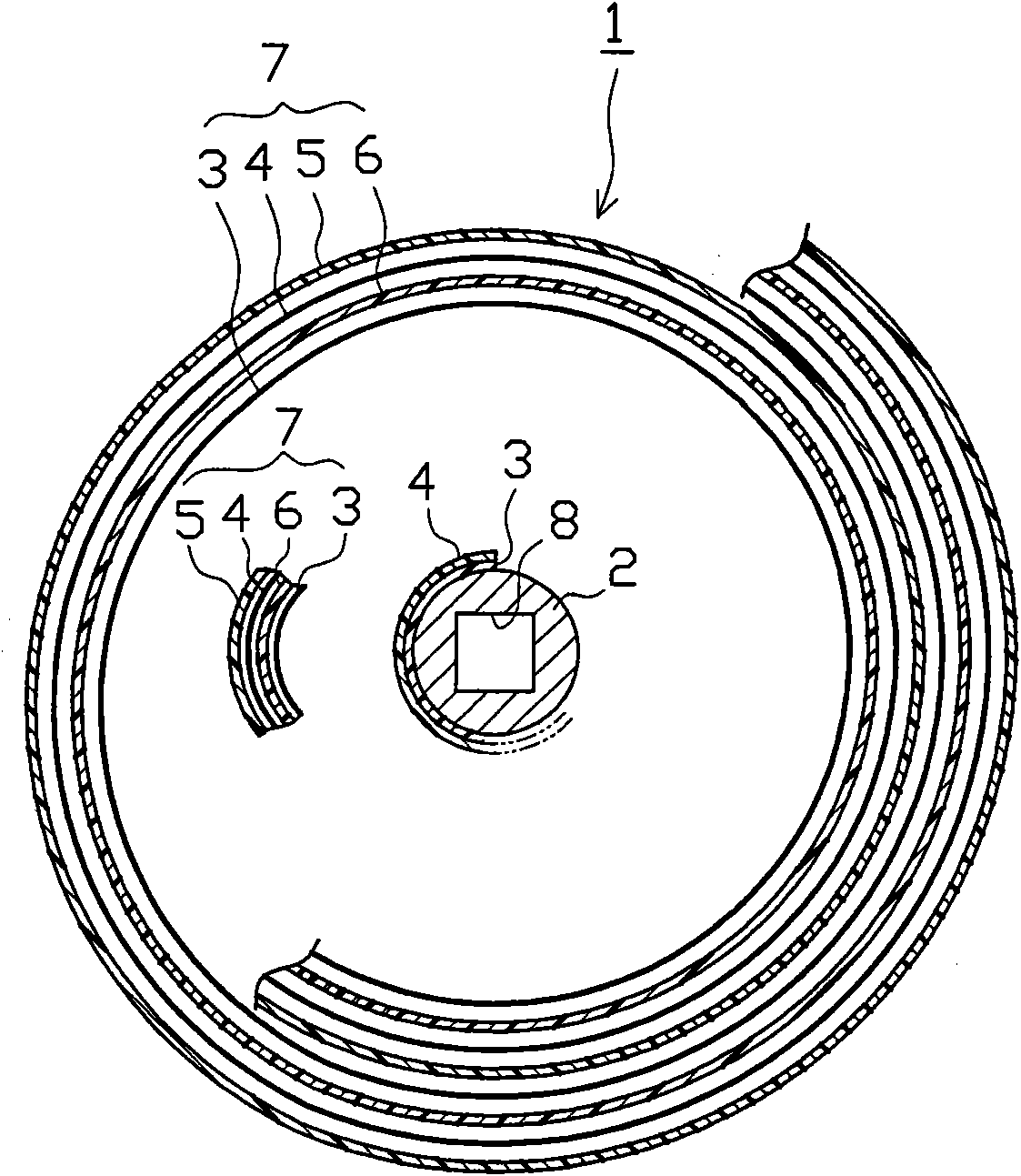

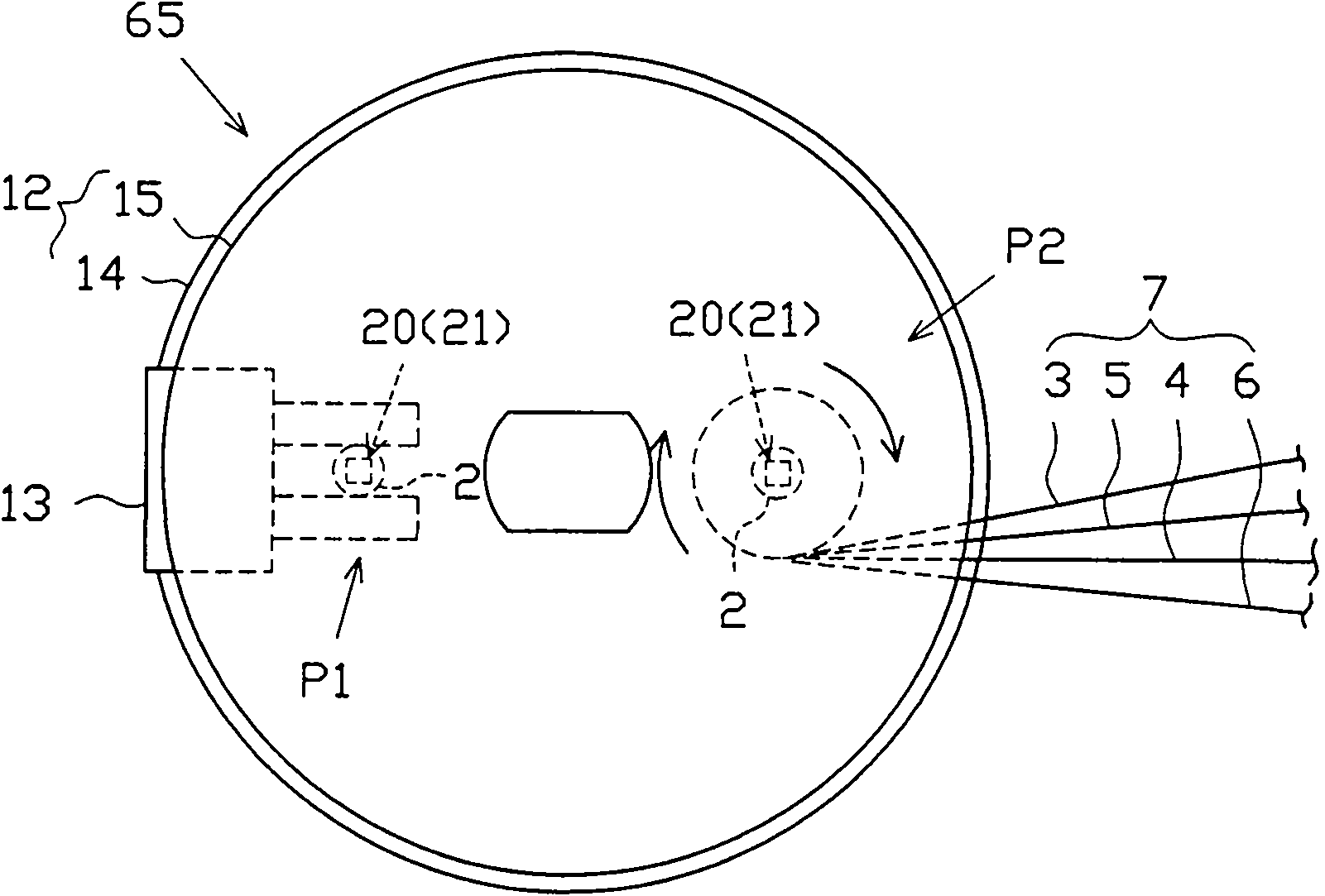

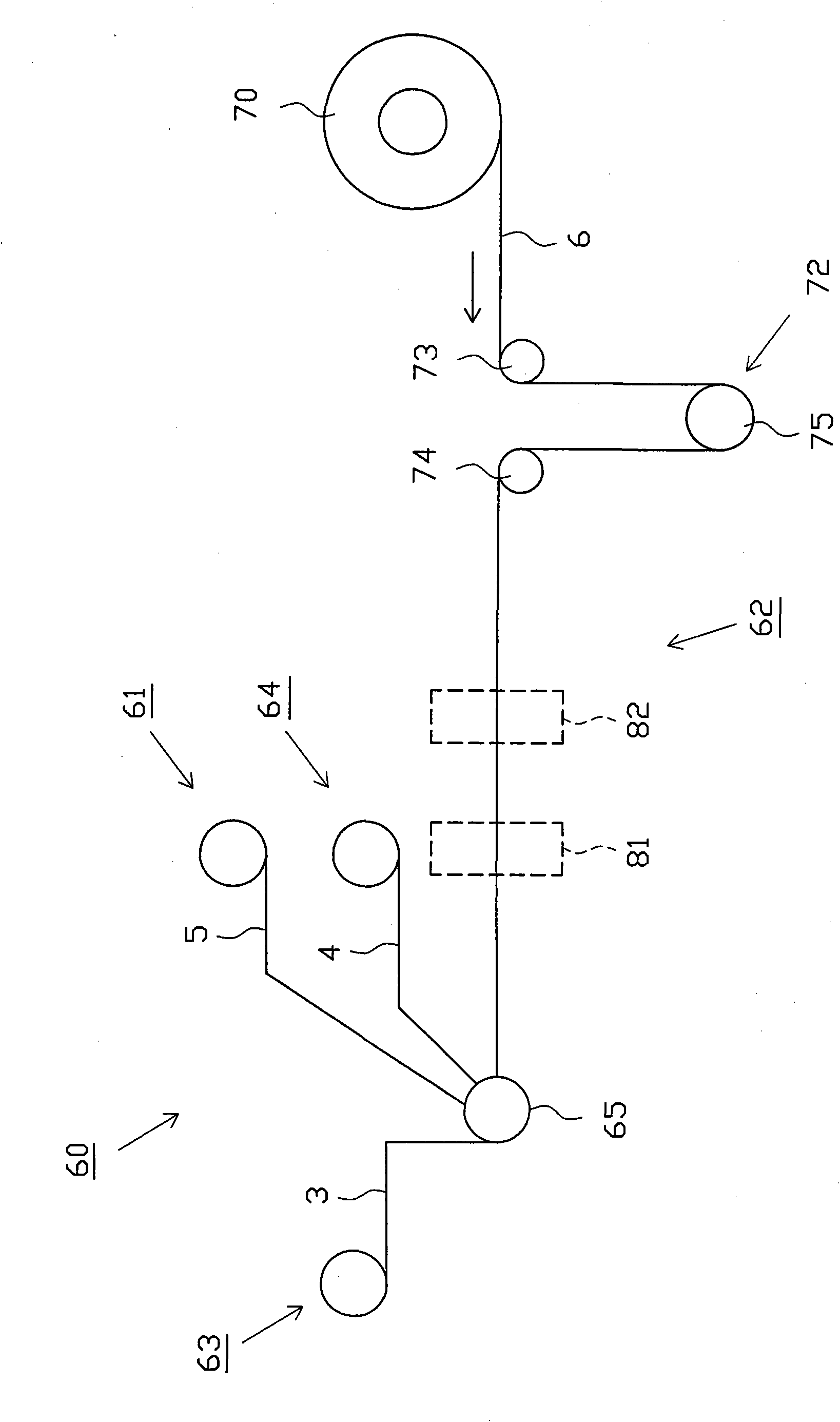

[0047] Such as figure 1 As shown, a lithium-ion battery element (hereinafter simply referred to as "battery element") 1 is constructed in such a manner that a strip-shaped body 7 passes through two separators 3, 4 and a cylindrical winding core body 2. The positive electrode sheet 5 and the negative electrode sheet 6 are composed of two electrode sheets. In addition, in figure 1 In FIG. 2 , for convenience of description, there are locations where the separators 3 and 4 , the positive electrode sheet 5 and the negative electrode sheet 6 are spaced apart from each other.

[0048] In this embodiment, the winding core body 2 is formed of a material having sufficient rigidity (for example, a metal material such as aluminum, or a resin material such as polypropylene (PP)). In addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com