Head unit, electrospinning head, and electrospinning apparatus

A technology of electrospinning and nozzles, which is applied in the directions of spinneret assemblies, textile and papermaking, filament/thread forming, etc., can solve the problems of complication of restraint structure and control system, reduction of productivity, increase of manufacturing cost, etc. The effect of suppressing the complexity of the structure and control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

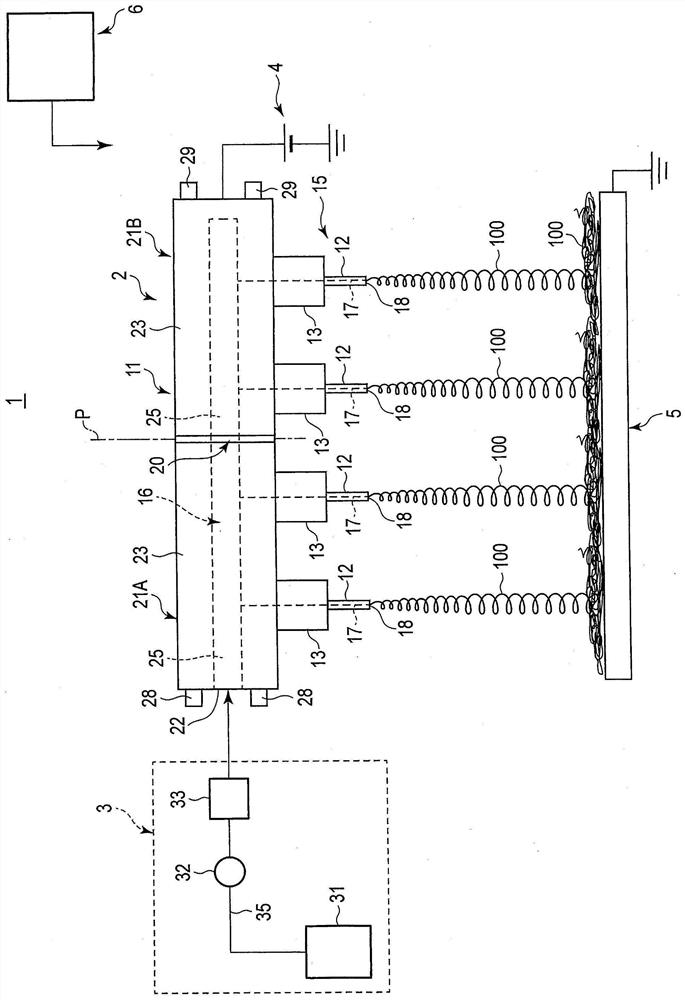

[0025] figure 1 An example of the electrospinning device 1 according to the first embodiment is shown. Such as figure 1 As shown, the electrospinning device 1 includes an electrospinning nozzle 2, a supply source (supply part) 3 of a raw material liquid, a power source 4, a collector 5, and a control part 6.

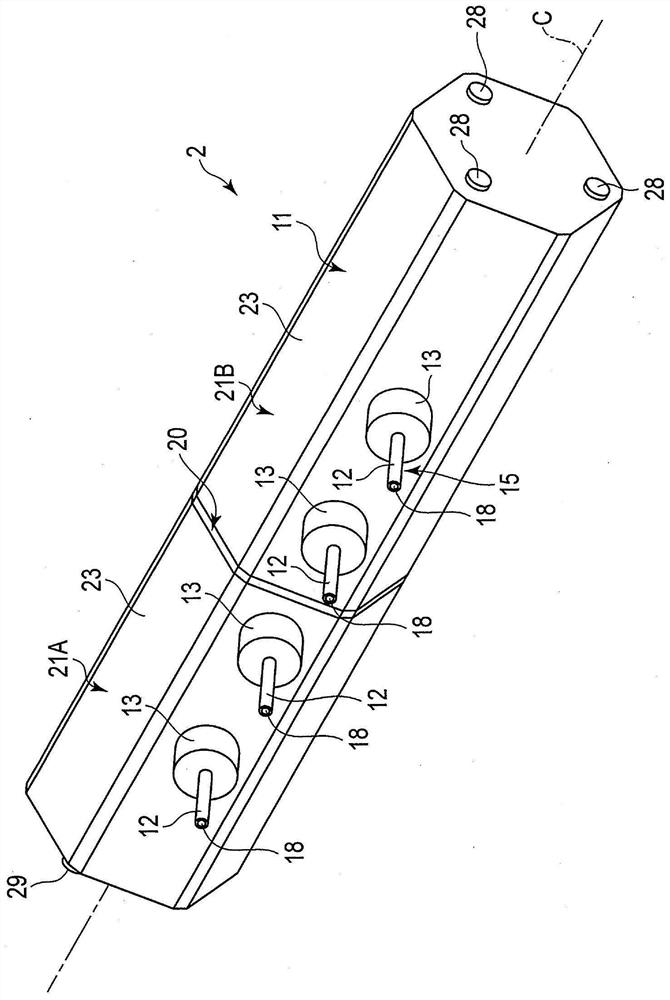

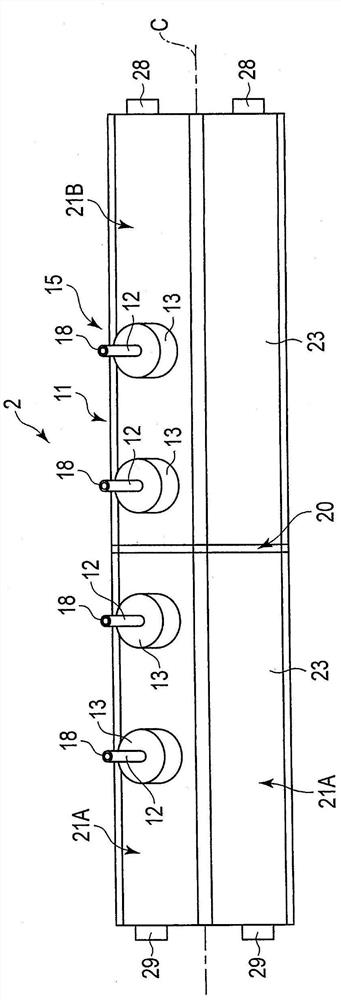

[0026] Figure 2 to Figure 5 Shows the structure of the electrospinning nozzle 2. Such as Figure 1 to Figure 5 As shown, the electrospinning nozzle 2 has a long side axis C as a central axis, and is arranged to extend along the long side axis C. The electrospinning nozzle 2 includes a nozzle body 11 and a plurality of (four in this embodiment) nozzles 12. In addition, the electrospinning nozzle 2 is provided with the same number of connection parts 13 as the nozzles 12, and the nozzles 12 are respectively connected to the nozzle body 11 via a corresponding one of the connection parts 13. In this embodiment, the shower head body 11, the nozzle 12, and the connection porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com