Wire-wound three-phase asynchronous motor with external electric brush and external slide ring

A three-phase asynchronous, winding-type technology, applied in the field of motors, can solve the problems of inconvenient installation and maintenance, inability to install fans, high cost, etc., and achieve the effect of compact structure, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

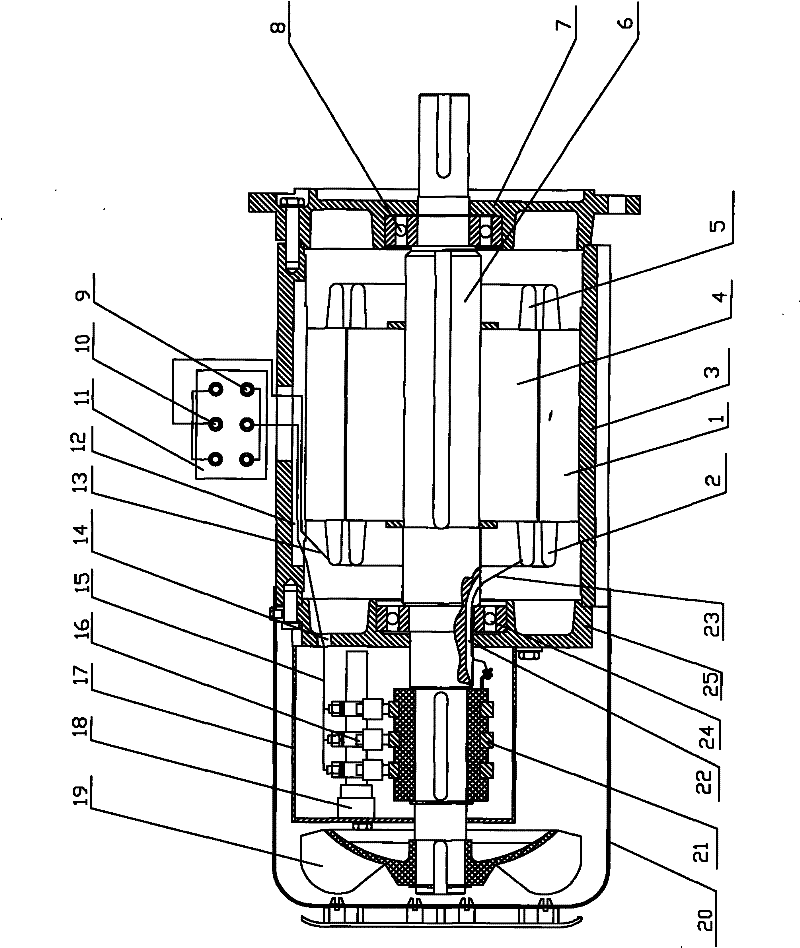

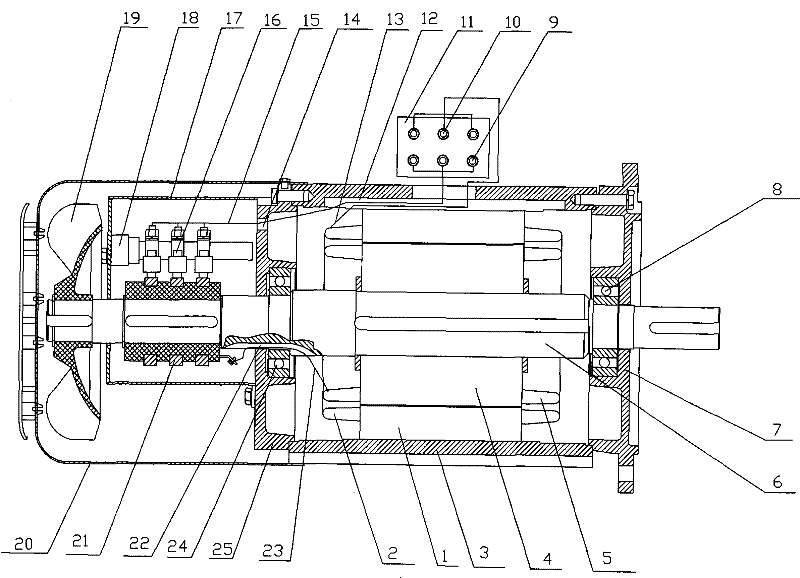

[0012] In the accompanying drawings, a wound three-phase asynchronous motor with external brushes and slip rings includes a stator core 1 , a stator winding 2 , a frame 3 , a rotor core 4 , a rotor winding 5 and a rotating shaft 6 .

[0013] The same as the publicly used technology, the stator winding 2 is embedded in the slot of the stator core 1, the stator core 1 is assembled in the frame 3, and the stator winding 2 is respectively passed through the lead slot in the frame 3 by the lead wire 13 12 is connected with the stator terminal 10 in the stator junction box 11 outside the frame 3 .

[0014] The rotor winding 5 is embedded in the slot of the rotor core 4, the rotor core 4 is fixed on the shaft 6, the rotor winding 5 is respectively passed through the lead slot 22 on the shaft 6 by the lead wire 23 and fixed on the non-axial extension of the shaft 6. Three mutually insulated slip rings 21 are connected on the end.

[0015] As shown in the accompanying drawings, one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com