Drive arrangement for a multi-axle driven motor vehicle

A drive assembly, multi-shaft transmission technology, applied in vehicle components, mechanical equipment, control devices, etc., can solve problems such as high fuel consumption, and achieve the effect of small structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

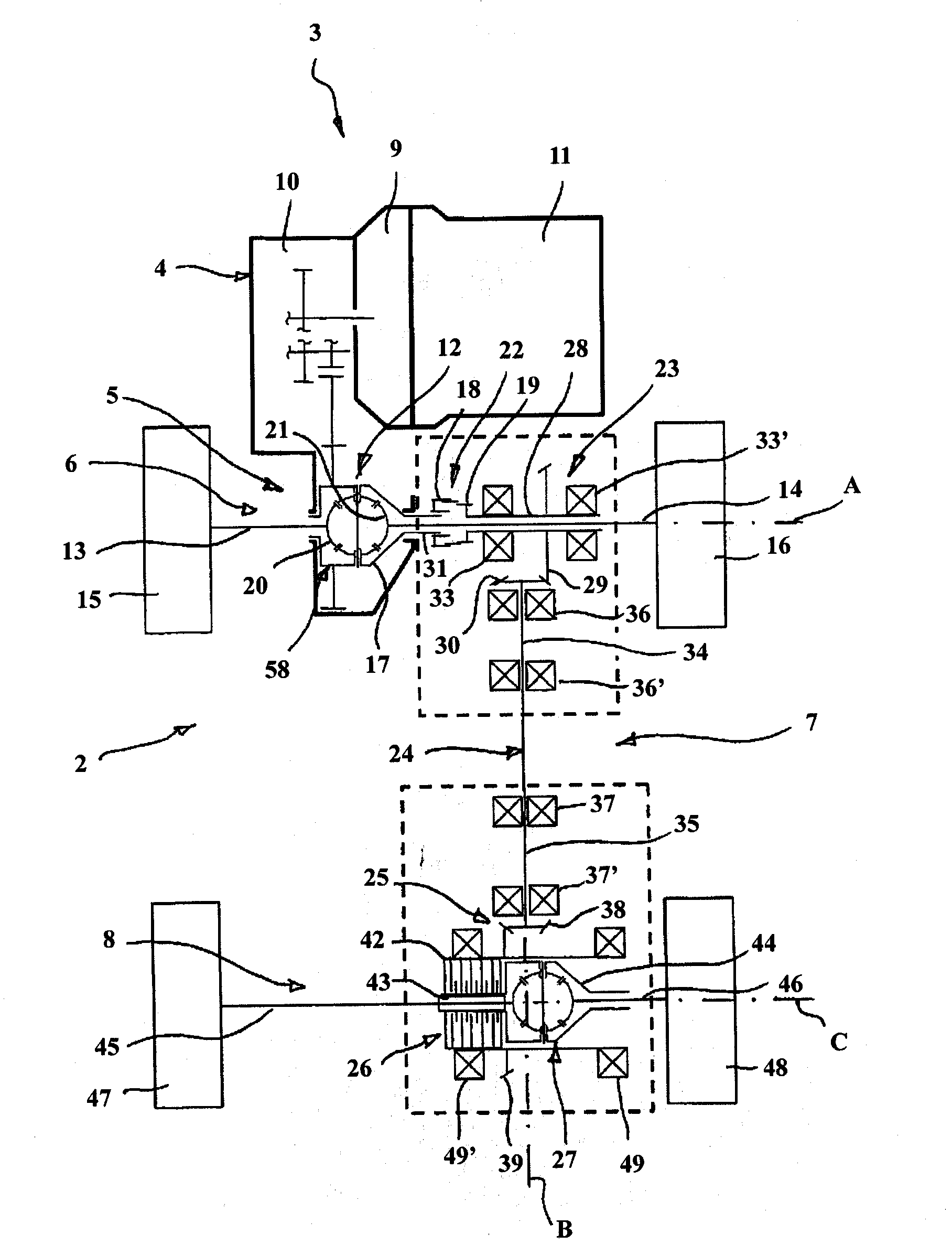

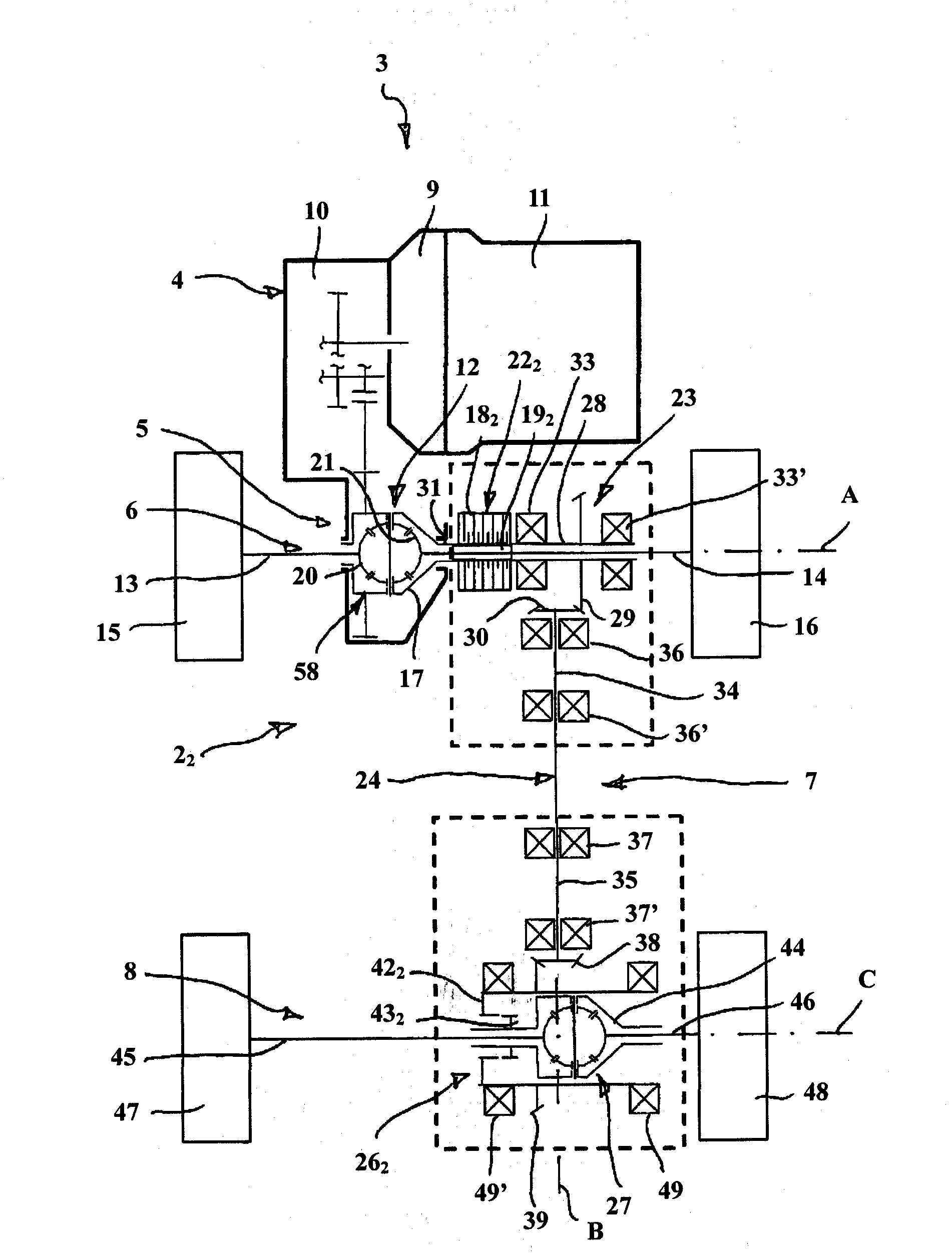

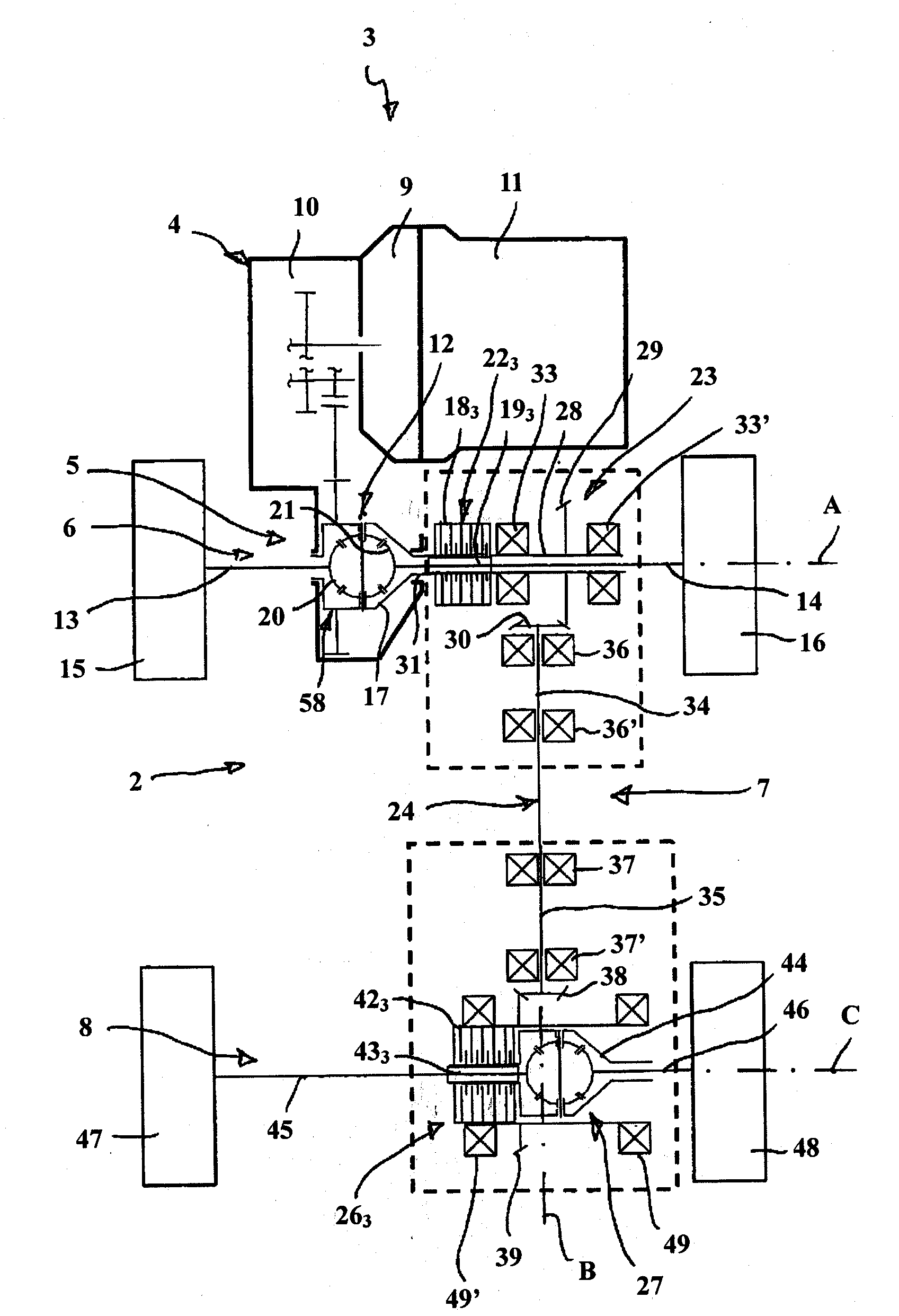

[0029] Figures 1 to 5 In view of their commonality, they are firstly described together. A drive unit 2 for a multi-shaft drive motor vehicle 3 is shown schematically. From motor vehicle 3 , a drive unit 4 , a first drive train 5 for driving a first drive shaft 6 and a second drive train 7 for driving a second drive shaft 8 can be discerned. The drive unit 4 includes an internal combustion engine 11 , a coupling 9 and a transmission 10 via which torque is introduced into the first and second drive train 5 , 7 . It is understandable that the drive unit can also be any other drive, such as a motor.

[0030] In order to distribute the torque generated by the drive unit to the first drive train 5 and the second drive train 7 , a splitter transmission 12 is provided. The splitter transmission 12 preferably comprises a differential transmission 58 having an input part 17 and three output parts 20 , 21 , 31 which have a balancing effect on one another. The input part 17 of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com