Control device and method for eliminating adhering strip steel of extremely thin material overlap joint welding machine magnetic scissors

A technology of control device and adhesive tape, which is applied to the attachments, shearing devices, auxiliary devices of shearing machines, etc., can solve the problems of poor purging effect, adsorption of strip steel by the blade, affecting the production capacity of the unit, etc., and achieve good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

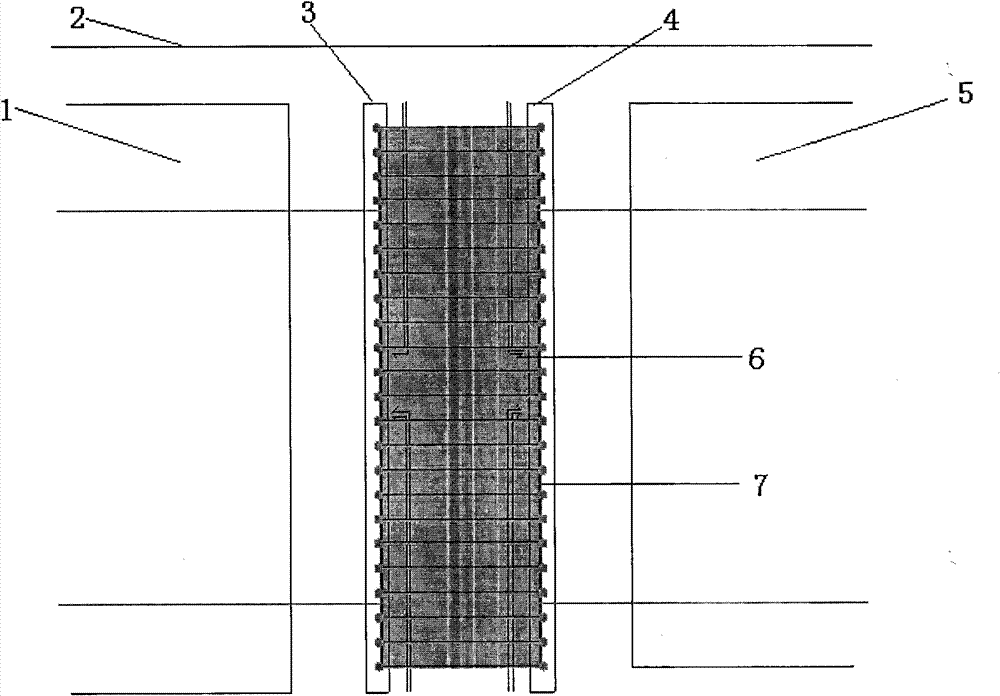

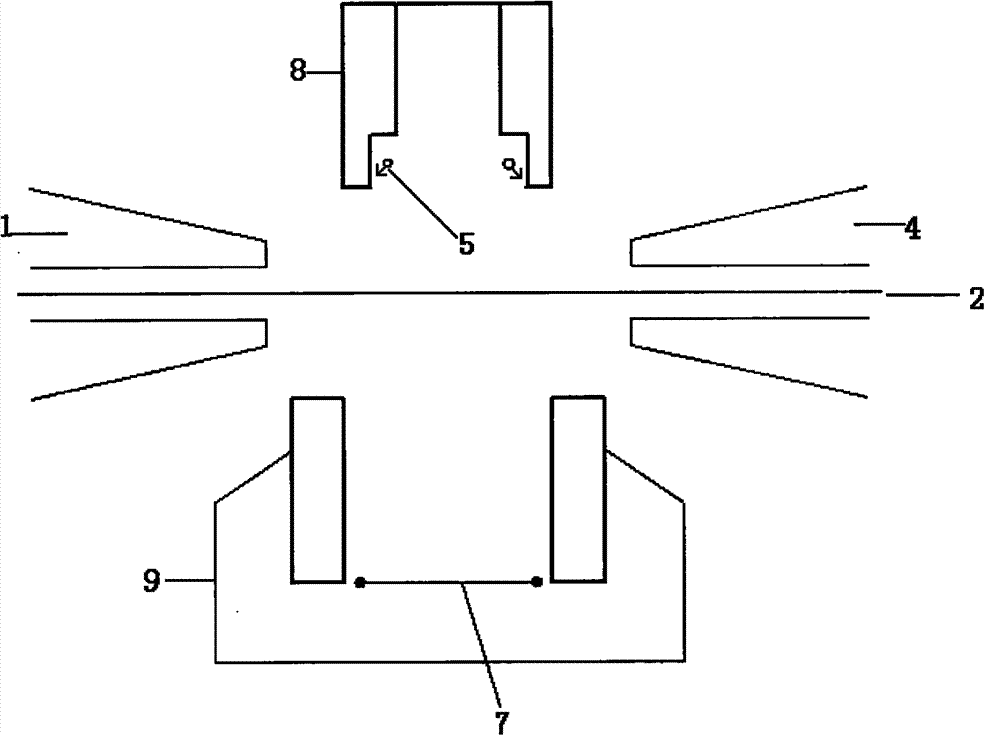

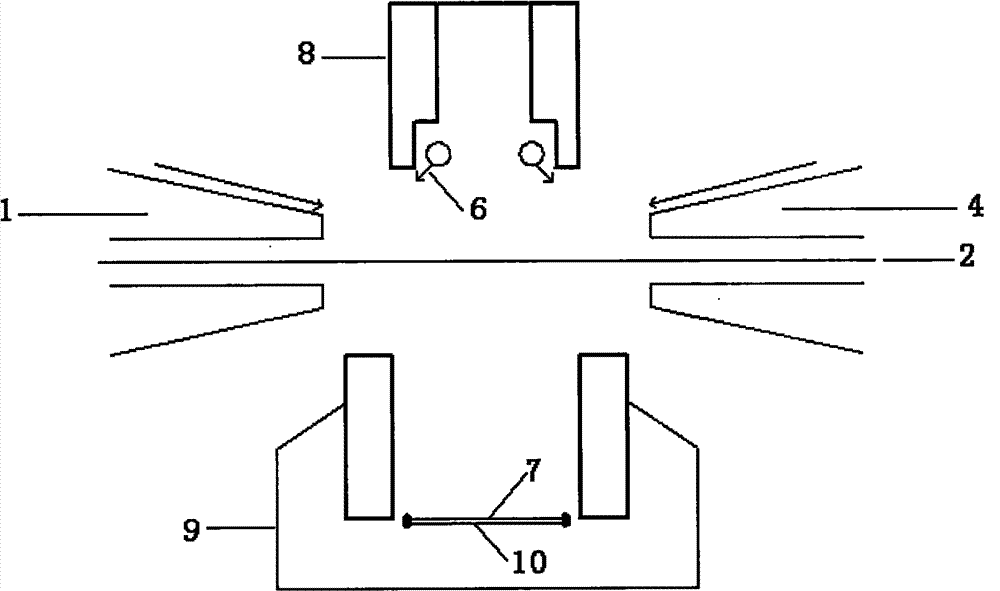

[0017] A control device and method for eliminating the adhesion of steel by the magnetic scissors of an ultra-thin material lap welding machine, changing the design idea of purging the copper tube in two ways in the traditional design, and adopting a four-way purging form. The originally installed copper tube is to be removed and replaced with a newly designed copper tube, two of which are respectively installed inside the blade, in the form of openings on the side of the copper tube, and the air blowing holes 11 are evenly arranged in the axial direction of the copper tube to align with the welding machine blade Perform a purge. (if attached image 3 , 4 shown). The other two roads are installed on the outside of the scissors of the welding machine, which are the outlet scissors 3 and the inlet scissors 4. Install the air pipe fixing bracket on the clamping guide plate of the welding machine inlet 5 and outlet 1, and evenly install a number of copper pipes on the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com