An engine transmission mechanism

A technology of transmission mechanism and engine, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems such as the inability to retain the shape of the cylinder block crankcase, the large error of installation, connection and assembly, to improve convenience, improve power performance, and eliminate dimensional deviations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

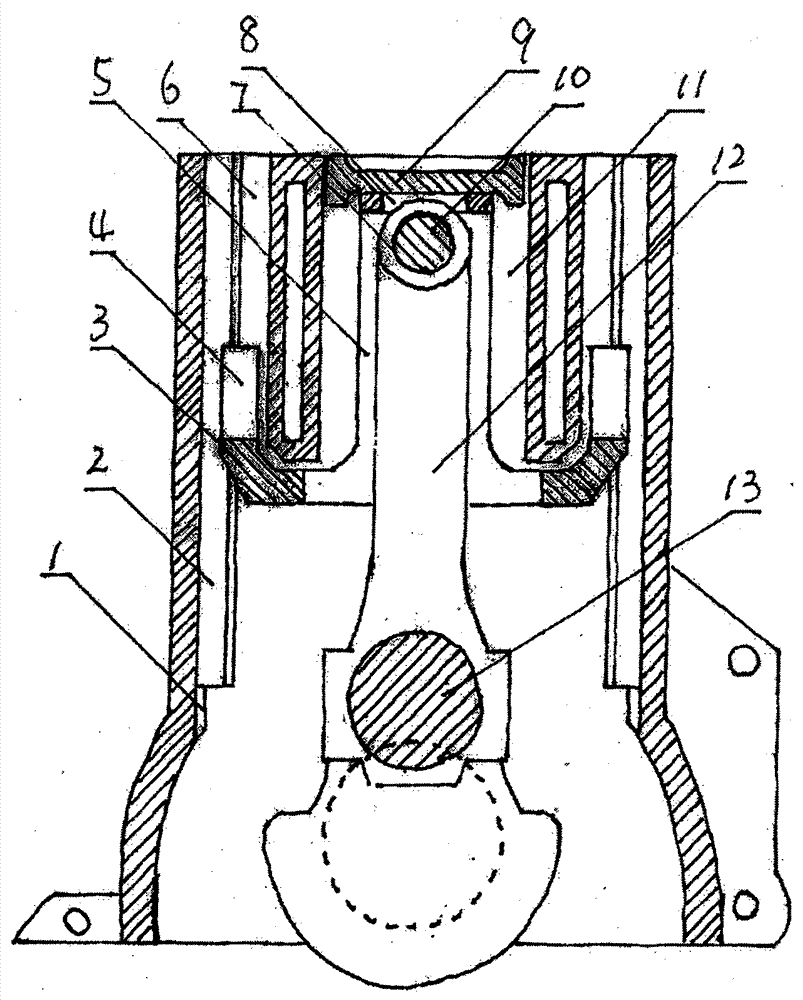

Embodiment 1

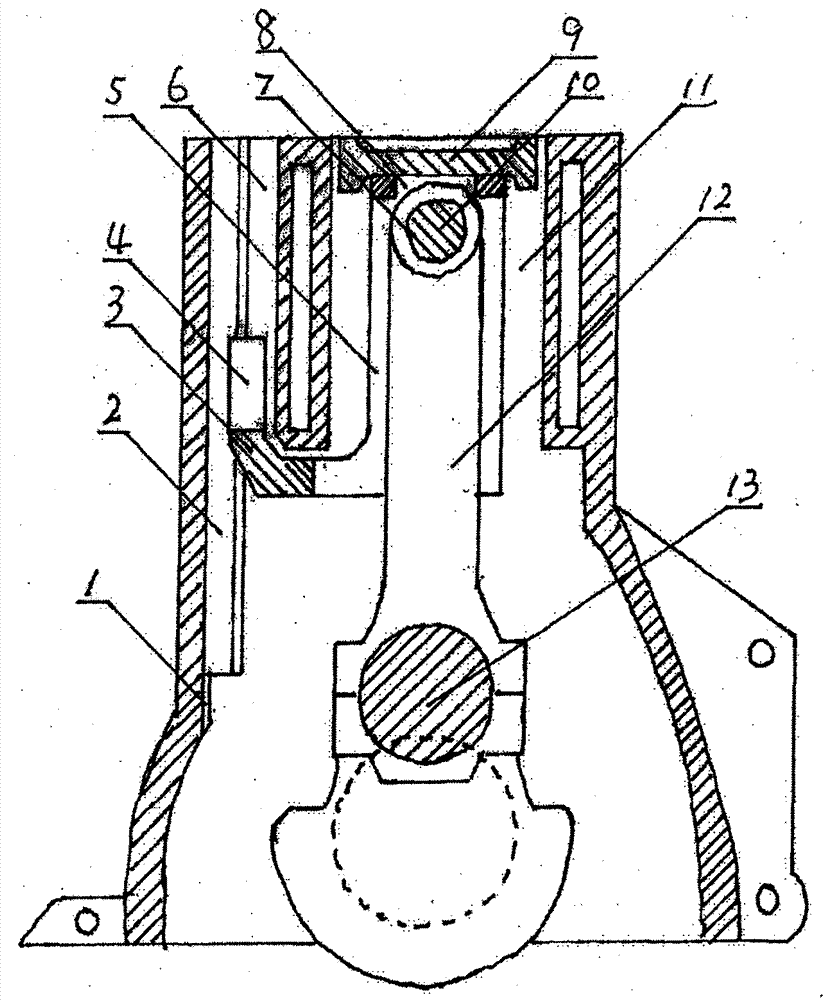

[0022] This example figure 2 As shown, the working principle and specific implementation are as above, the difference is that the slider part is a sliding slider part; The guide rail components form a moving pair; the cylinders are arranged in-line, the diameter of the cylinder is 74mm, the height of the piston is 55mm, and the piston pin seat is reserved. After canceling the piston skirt structure, the piston only retains the 22mm part of the head, and the height of the piston skirt is reduced by 33mm. The cylinder height of 33mm required by the original piston skirt guide, the length of the crank can be increased by 15% on the original basis, and the length of the crank can be increased on the basis of eliminating the friction loss between the original piston and the cylinder due to side pressure Size, increase the piston stroke to improve the power performance of the engine.

Embodiment 2

[0024] This embodiment is as described in Embodiment 1, the difference is that the cylinders are arranged in a V shape; the slider part is a rolling slider part; the rolling slider part and the linear motion guide rail part form a moving pair, which is obliquely assembled and fixed on the V-shaped cylinder On the inner walls of both sides, the sliding block is replaced by the sliding block to greatly reduce the friction loss, and further improve the power performance of the engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com