Mold for manufacturing filter screen assembly and manufacturing method thereof

A manufacturing method and filter net technology, applied in the field of molds for filter net components, can solve problems such as potential safety hazards, low pass rate, easy to cut fingers, etc., and achieve the effects of eliminating safety accidents, improving product pass rate, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

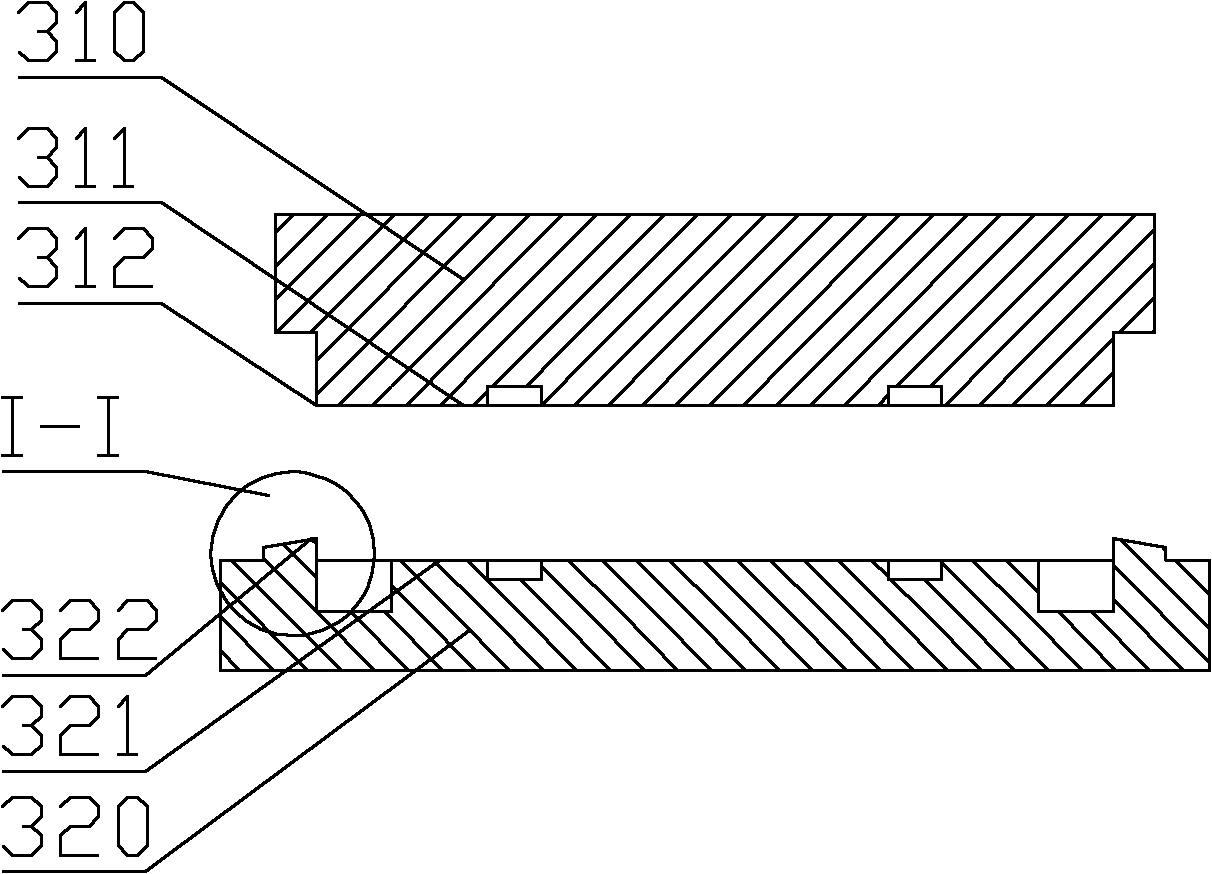

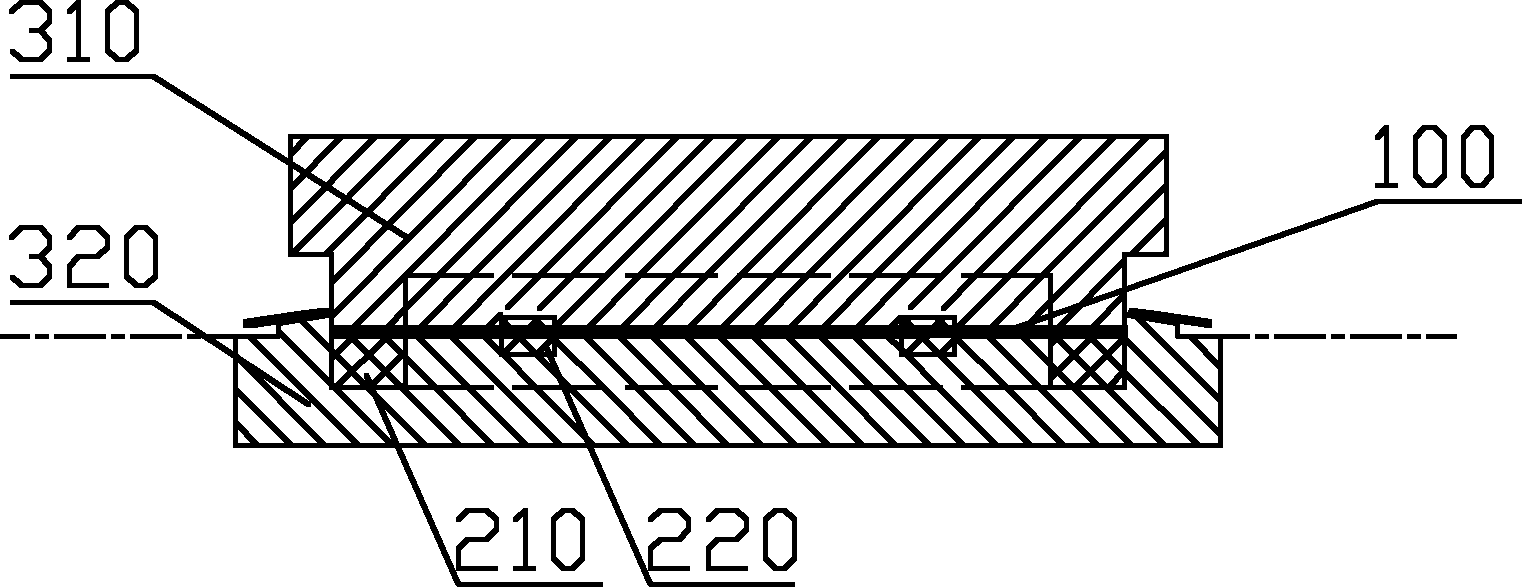

[0048] In the first embodiment, the second cutting edge 322 is located outside the second parting surface 321, the first cutting edge 312 is flush with the first parting surface 311, and the second cutting edge 322 cooperates with the first cutting edge 312 to form a cutting edge. The position is above the first parting surface 311 and above the second parting surface 312 (with figure 2 For reference); according to actual needs, those skilled in the art can appropriately change the positions of the second cutting edge 322 and the first cutting edge 312, so that the cutting position formed by the cooperation of the second cutting edge 322 and the first cutting edge 312 is located at the first point Below the profile 311 .

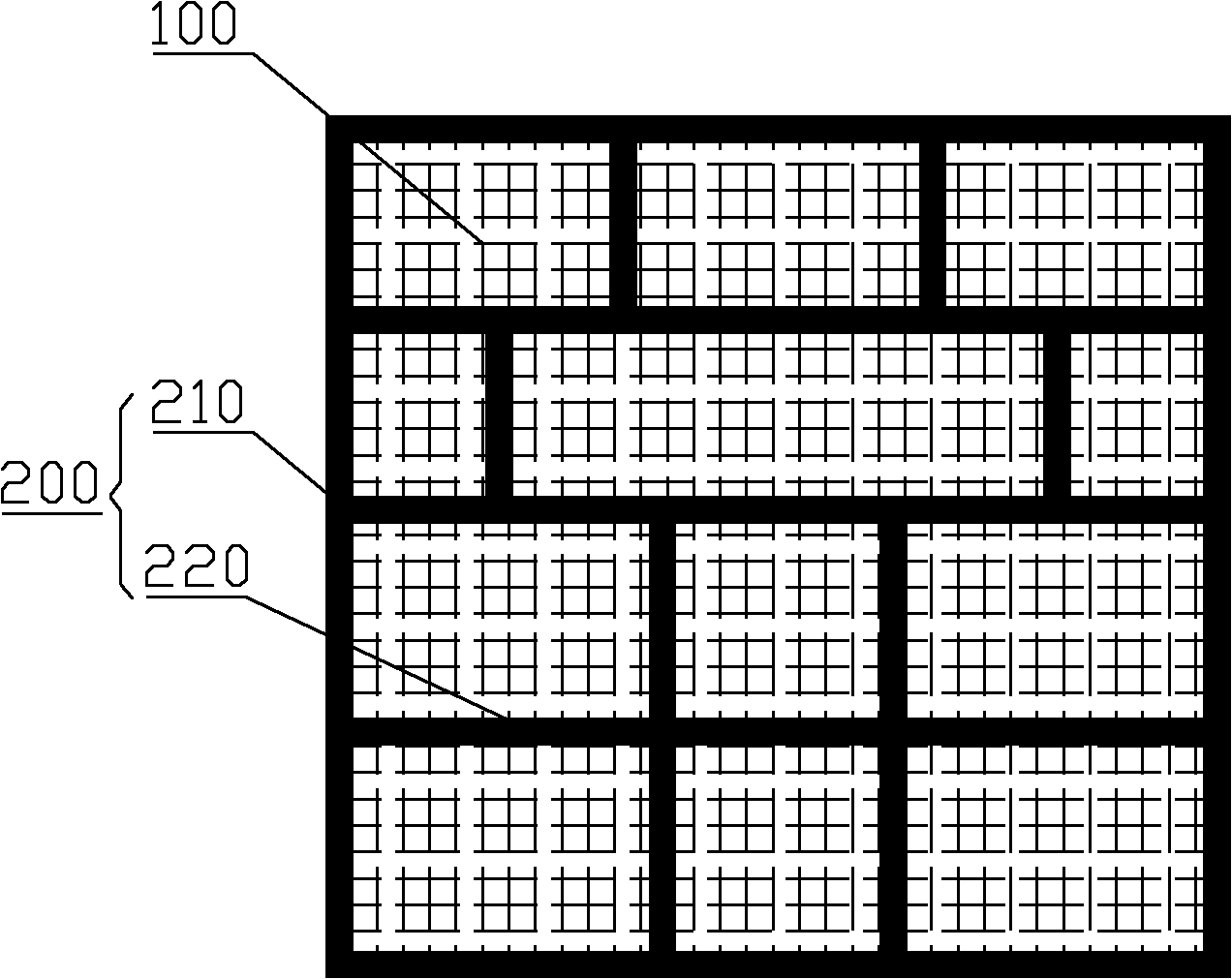

[0049] In the filter screen assembly formed by injection molding with the mold provided in Embodiment 1, the side frame 210 is located on one side of the mesh body 100 . The mold provided by Embodiment 2 of the present invention can make the side frame 210...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com