Etching method for liquid crystal glass panel

A liquid crystal glass and panel technology, which is applied in the field of etching of liquid crystal glass panels, can solve problems such as low production efficiency, uneven thickness of liquid crystal glass panel etching, formation of spots, etc., and achieves improved production efficiency, etching quality assurance, and uniform etching thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

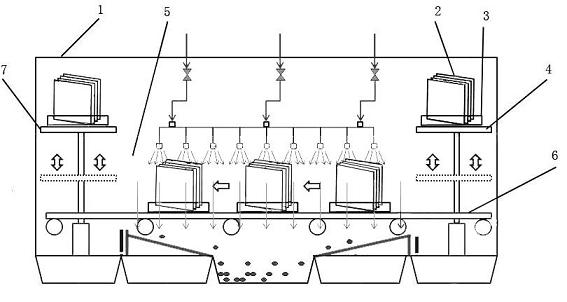

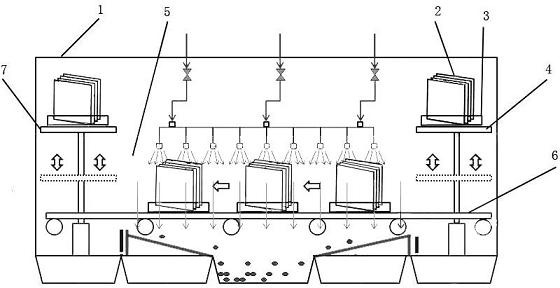

[0017] The following combination figure 1 Specific embodiments of the present invention are described in detail.

[0018] First, take a certain concentration of chemical etching solution, the temperature is above 20°C, pour it into the etching container 1, the depth is enough to immerse the liquid crystal glass panels 2, and then fix a group of liquid crystal glass panels 2 on a tray 3 upright, the The tray is placed on the import bracket 4, and the import bracket is movably installed in the etching container 1, and there is a certain gap between each liquid crystal glass panel, so that the liquid medicine can flow therein. The lead-in bracket 4 moves downward to completely immerse the liquid crystal glass panel in the chemical etching solution 5, and then the group of liquid crystal glass panels moves forward on the conveyor belt 6 installed in the etching container for etching. When it moves to the lead-out bracket 7 at the other end of the conveyor belt at a specified spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com