Preparation method of patterned zinc oxide film

A zinc oxide thin film and patterning technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as high cost, low efficiency, and complicated process procedures, and achieve high repeatability and cheap preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

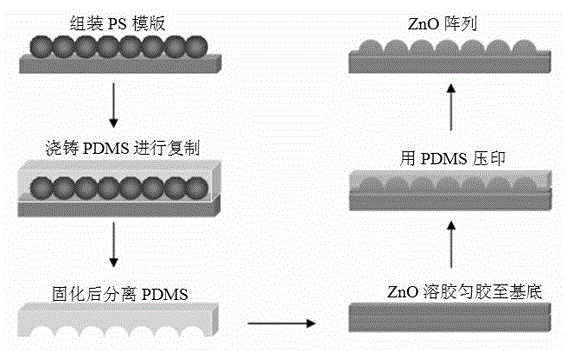

[0027] A method for preparing a patterned zinc oxide film, comprising the following steps:

[0028] (1) Preparation of colloidal ball template

[0029] a, the preparation of polystyrene ball suspension, polystyrene ball is dissolved in the mixed solvent of water and ethanol, the mass percentage of polystyrene ball in the polystyrene ball suspension is 1%, the mass ratio of water and ethanol 1:1, the diameter of the polystyrene ball is 100nm;

[0030] b. Use a dropper with a rubber tip to absorb the polystyrene ball suspension and drop it onto the glass slide, then place one end of the glass slide in contact with the surface of deionized water at an angle of 20° and slowly penetrate below the water surface. At this time, the PS on the glass slide The suspension spread rapidly on the water surface, and at the same time self-assembled into a single-layer polystyrene film at the gas-liquid interface; The styrene film is transferred to the substrate, and dried at 90°C to obtain a...

Embodiment 2

[0038] A method for preparing a patterned zinc oxide film, comprising the following steps:

[0039] (1) Preparation of colloidal ball template

[0040] a, the preparation of polystyrene ball suspension, polystyrene ball is dissolved in the mixed solvent of water and ethanol, the mass percent of polystyrene ball in the polystyrene ball suspension is 3%, the mass ratio of water and ethanol 1:2, the ball diameter of polystyrene ball is 300nm;

[0041]b. Use a dropper with a rubber tip to absorb the polystyrene ball suspension and drop it onto the glass slide, then place one end of the glass slide in contact with the surface of deionized water at an angle of 25° and slowly penetrate below the water surface. At this time, the PS on the glass slide The suspension spreads rapidly on the water surface, and self-assembles into a single-layer polystyrene film at the gas-liquid interface; The polystyrene film was transferred to the substrate, and dried at 80°C to obtain a colloidal bal...

Embodiment 3

[0049] A method for preparing a patterned zinc oxide film, comprising the following steps:

[0050] (1) Preparation of colloidal ball template

[0051] a, the preparation of polystyrene ball suspension, polystyrene ball is dissolved in the mixed solvent of water and ethanol, the mass percent of polystyrene ball in the polystyrene ball suspension is 5%, the mass ratio of water and ethanol The ratio is 1:3, and the diameter of the polystyrene ball is 500nm;

[0052] b. Use a dropper with a rubber tip to absorb the polystyrene ball suspension and drop it onto the glass slide, then place one end of the glass slide in contact with the deionized water surface at an angle of 30° and slowly penetrate below the water surface. At this time, the PS on the glass slide The suspension spread rapidly on the water surface, and at the same time self-assembled into a single-layer polystyrene film at the gas-liquid interface; The styrene film was transferred to the substrate, and dried at 120°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com