Method and system for controlling automatic growth of zone-melt crystal by adopting diameter process

A technology of automatic growth and control area, which is applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc. It can solve the problems of long artificial crystal pulling time, poor control of single crystal quality, and large human influence factors, so as to reduce artificial Labor intensity, reduce errors and losses, improve the effect of consistency quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

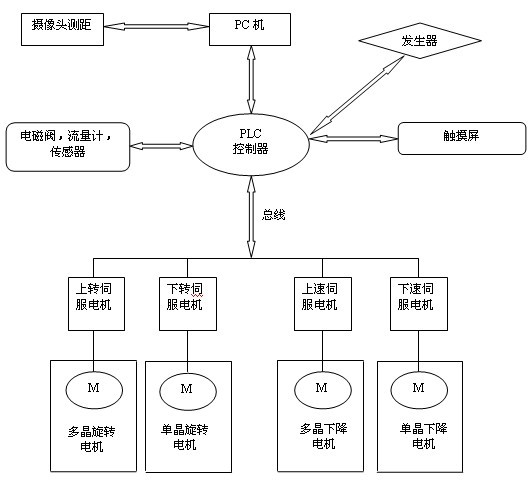

Method used

Image

Examples

Embodiment Construction

[0027] A specific implementation case of automatic growth of a Φ6" zone melting single crystal is given below to further illustrate how the present invention is realized.

[0028] The specific steps of automatic growth of Φ6" zone melting single crystal are as follows:

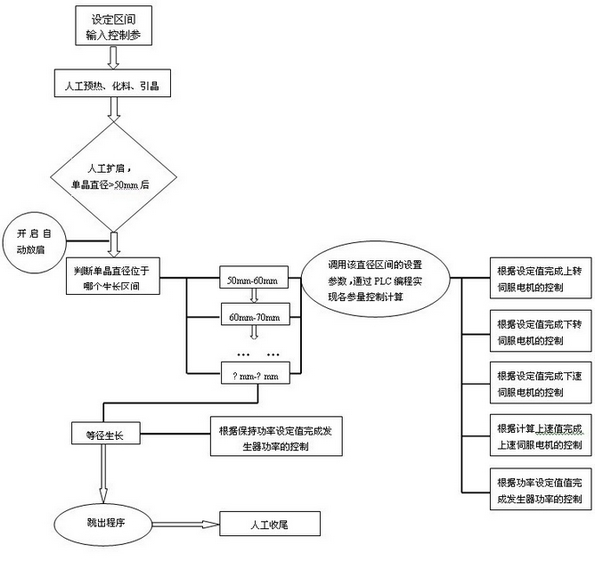

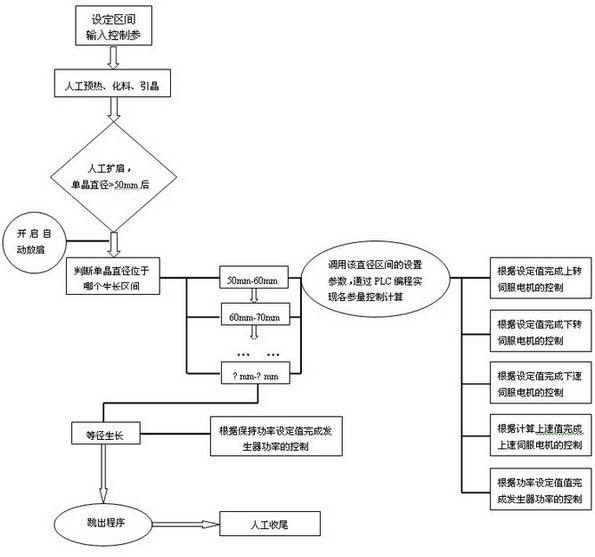

[0029] (1) Set the growth interval and set the control parameters

[0030] Set the diameter range, taking this implementation as an example, the set range is 50-60mm, 60-70mm, 70-80mm, 80-90mm, 90-100mm, 100-110mm, 110-120 mm, 120-130mm, 130- 140mm, 140-152mm. Then set the control parameter options of each automatic shoulder single crystal diameter interval based on empirical data, for example: in the corresponding set diameter interval 60-70mm, set V lower The falling speed of the single crystal is 3.6mm / min, the power of the generator is 22kw, the rotation speed of the single crystal is 7.5rpm, the rotation speed of the polycrystal is 0.30rpm, R growth The growth rate of the single crystal is 4.0mm / dia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com