Laser pulse deposition system and processing method

A technology of laser pulse deposition and pulsed light source, applied in the laser field, can solve the problems of small surface area, low film deposition rate, poor film uniformity, etc., and achieve the effect of improving uniformity, good anti-misalignment characteristics, and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

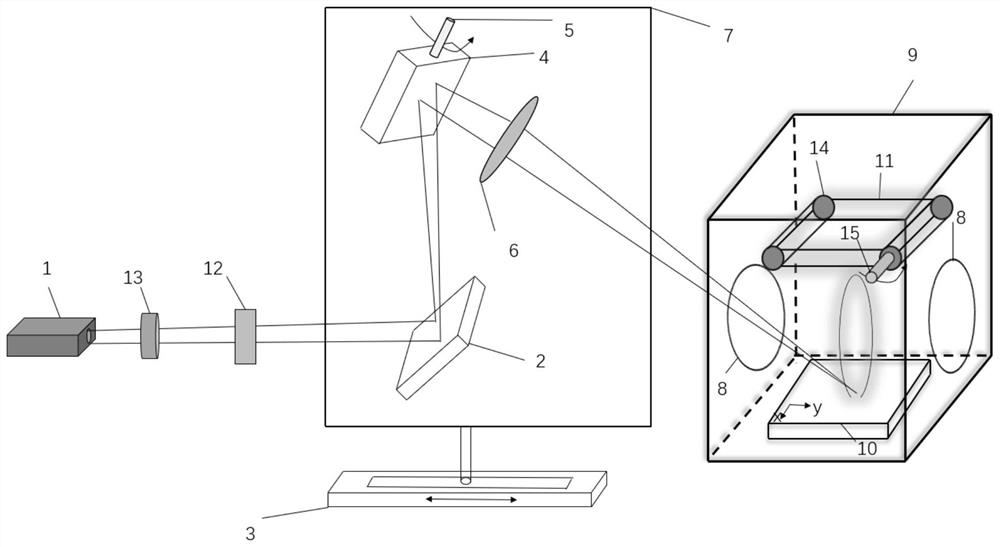

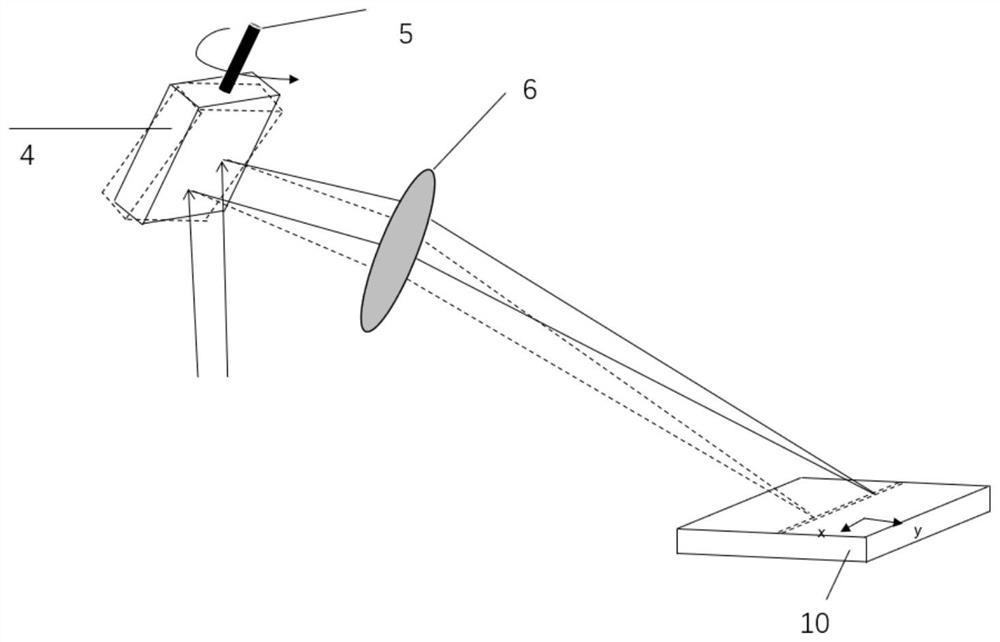

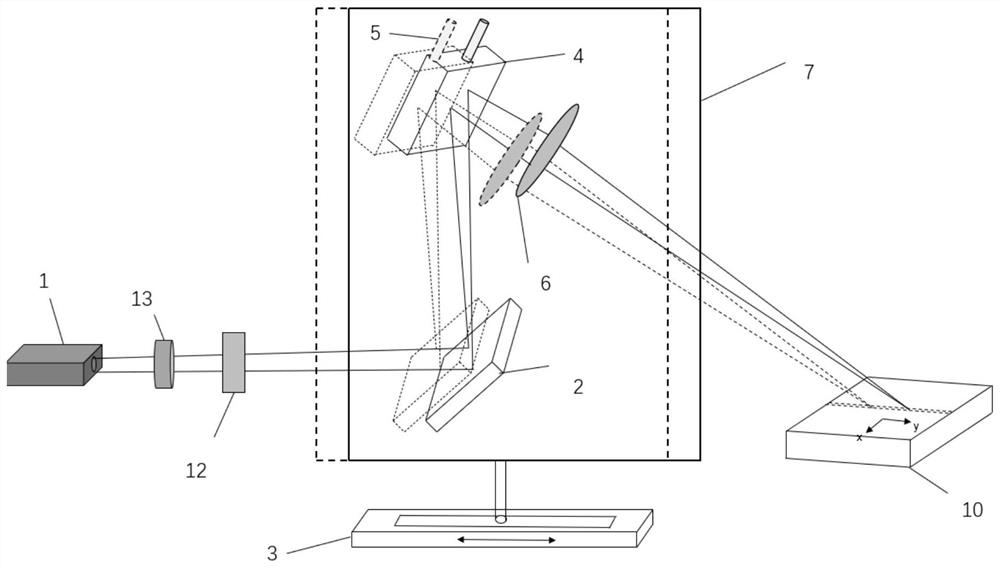

[0043] Such as figure 1 As shown, a new type of laser pulse deposition system provided by the embodiment of the present invention includes a high repetition rate, low energy all-solid-state laser 1, a 45° mirror 2, a first motor and a guide rail 3 for moving the movable optical table 7, One-dimensional galvanometer 4, second motor 5 for driving galvanometer vibration, standard flat-field focusing lens 6, movable optical platform 7, incident window 8, vacuum cavity 9, target 10, substrate 11, diffractive optical element 12 , a collimating beam expander element 13, a rotating shaft 14, and a rotating shaft 15 with a motor.

[0044] The beam emitted by the all-solid-state laser 1 is collimated by the collimating beam expander unit 13 and then enters the diffractive optical element 12, modulated by the diffractive optical element 12 and then transmitted to the mirror 2, and the beam is reflected by the mirror 2 and then enters the one-dimensional vibrating mirror 4. Reflected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com