Capacitive micro machinery gyroscope

A technology of capacitive micromachines and gyroscopes, which is applied in the direction of gyroscope effect for speed measurement, gyroscope/steering sensing equipment, measuring devices, etc., can solve problems such as difficult to achieve, small change in resonant frequency of resonators, high sensitivity, etc., to achieve The effect of increasing the sensitivity and increasing the amount of capacitance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

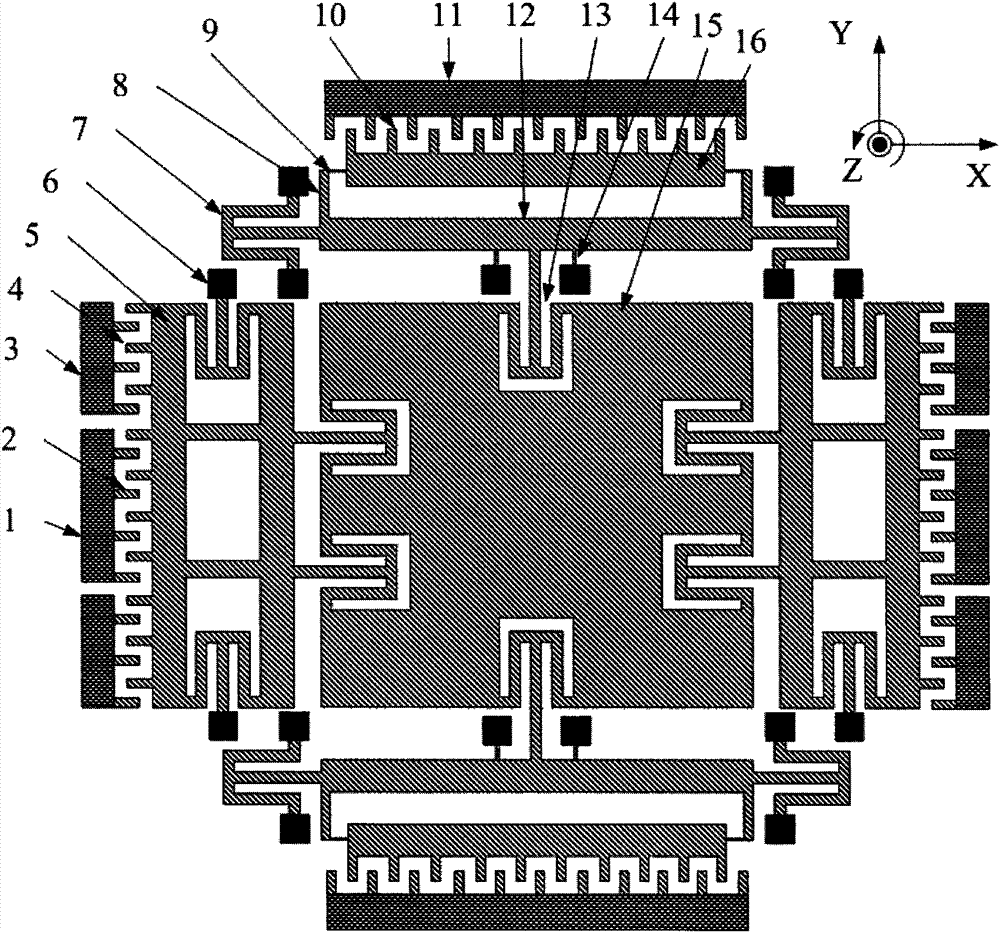

[0014] Specific embodiments of the present invention: as figure 1 As shown, the technical solution adopted in the present invention is: a capacitive micromechanical gyroscope, comprising a mass block 15; defining the center of the mass block 15 as the origin, the direction parallel to one side of the mass block is the X direction, and the direction parallel to the other side is In the Y direction, the capacitive micromechanical gyroscope is symmetrical about the Y axis in the X direction, and symmetrical about the X axis in the Y axis direction;

[0015] The mass block 15 is connected to the driving frame beam 5 through the folding beam II13 connected to its Y-direction side, and the driving frame beam 5 is connected to the anchor point through the folding beam I7; the part fixed on the driving frame beam 5 drives the dynamic comb The teeth and the driving static comb teeth fixed on the driving electrode 3 form a driving comb tooth pair 4, so that the driving frame beam 5 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com