Near infrared calibration board design method

A technology of calibration template and design method, applied in the field of optical measurement, can solve problems such as the design method of active near-infrared calibration plate that has not yet been seen, and achieve the effects of strong resistance to changes in ambient light, high manufacturing accuracy and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical solution of the present invention, a further detailed description will be given below in conjunction with the drawings and the design process of the calibration plate.

[0023] The invention relates to a design method of a near-infrared calibration board. The calibration board designed and produced by the method of the invention can accurately calibrate a near-infrared imaging system.

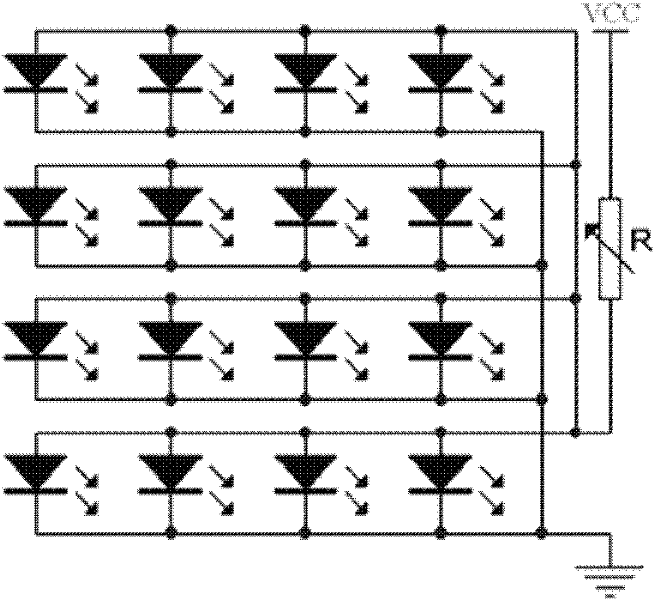

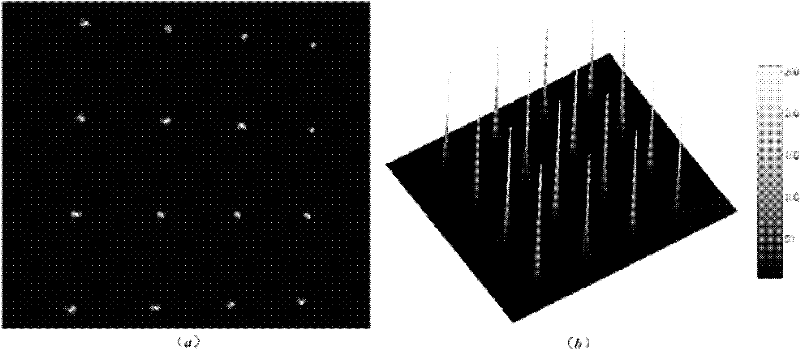

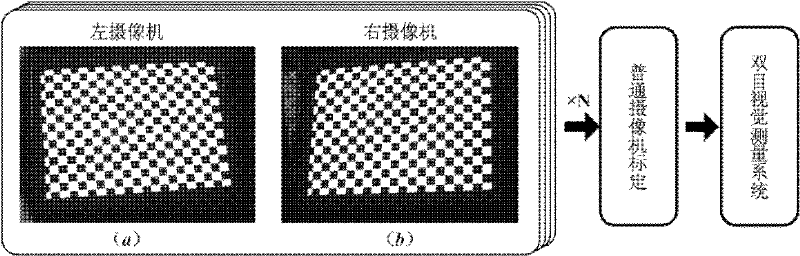

[0024] The calibration board is arranged in a 4×4 array of near-infrared light-emitting patch elements, and is connected in parallel to form a regular and consistent calibration board. Move the calibration plate in the ordinary optical measurement system calibrated by the calibration method of the liquid crystal flat screen to obtain multiple sets of images of the calibration plate, and then extract the sub-pixel coordinates of the luminous points in each set of images, and finally through the ordinary optical binocular vision measurement system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com