Brazing filler metal turbulent flow wave crest generator

A generator and wave crest technology, applied in the field of solder turbulence wave crest generators, can solve the problems of continuous welding and solder leakage, liquid flow disorder, product defect rate, repair rate, etc., and achieve lead-free welding with high quality and impact force. proper effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

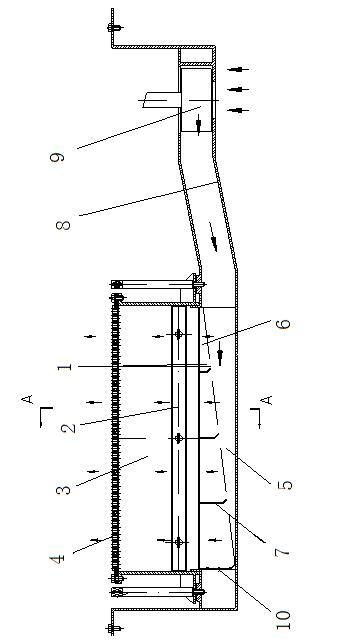

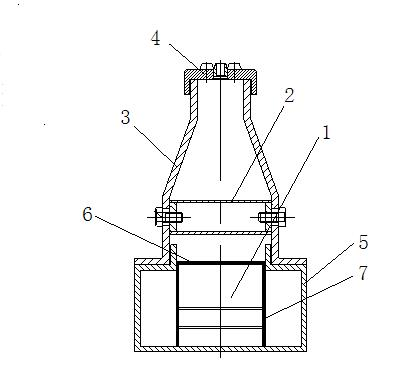

[0020] A solder turbulence wave crest generator is characterized in that it is composed of a deflector 1, a rectifier 2, a flow stabilizer 3 and a sprayer 4.

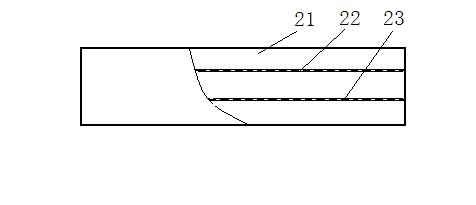

[0021] The deflector 1 in the present invention is made up of deflector groove 5, deflector net 6, deflector plate 7, deflector pipe 8 and centrifugal pump 9, and deflector groove 5 is provided with deflector net 6, deflector , 6 is a flat plate evenly distributed with round holes, the front end of the diversion groove 5 is provided with a baffle plate 10, the rear end of the diversion groove 5 is connected with the diversion pipe 8, and the other end of the diversion pipe 8 is provided with a centrifugal pump 9, The cross-section of the diversion groove 5 and the diversion pipe 8 is square, and a deflector 7 is arranged in the diversion groove 5, and the upper end of the diversion plate 7 is in contact with or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com