Flaxseed husking method and matched equipment

A kind of supporting equipment, flaxseed technology, applied in chemical instruments and methods, grain hulling, separation of solids from solids by air flow, etc. The problem of low shelling efficiency is to achieve the effect of ensuring the quality of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

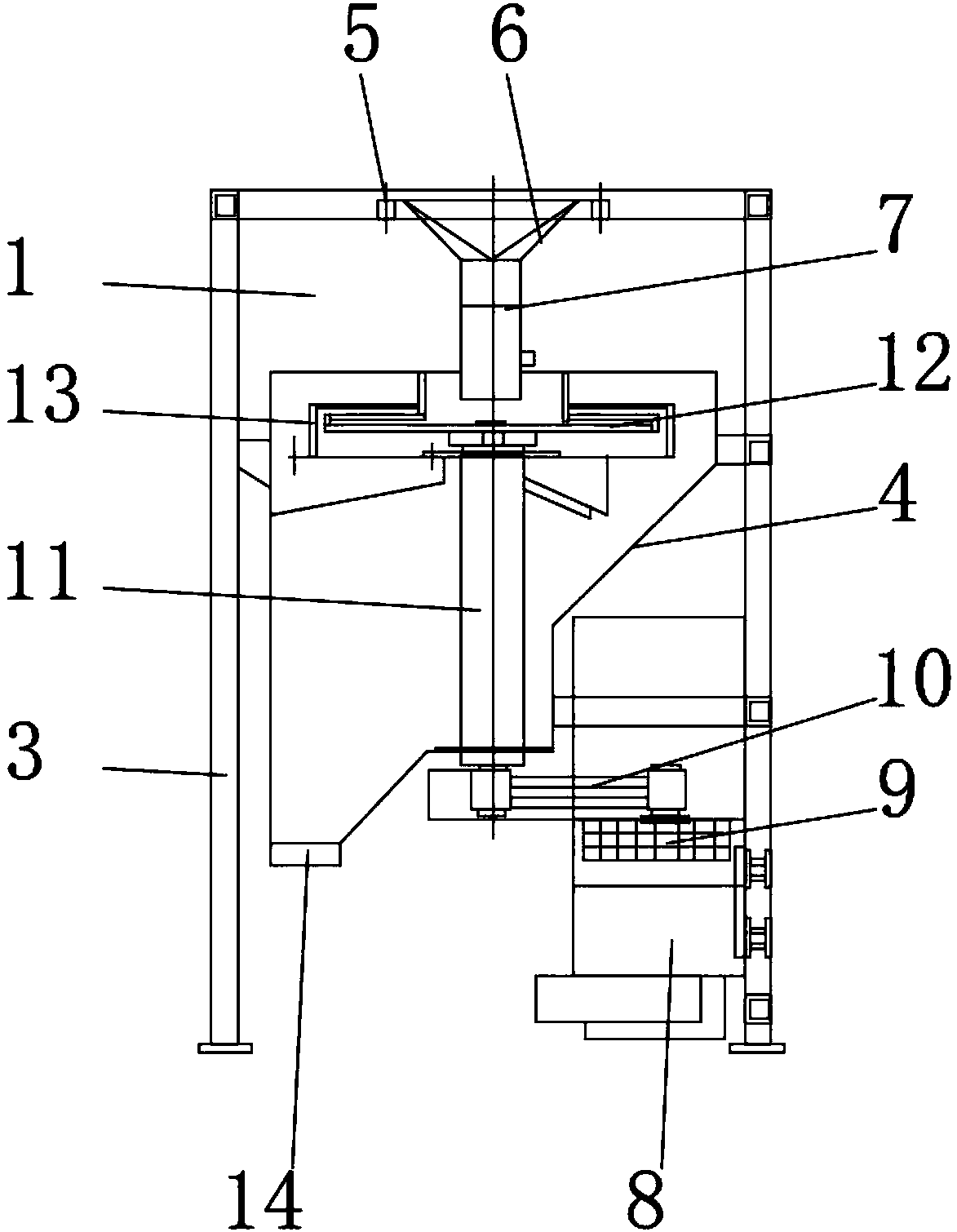

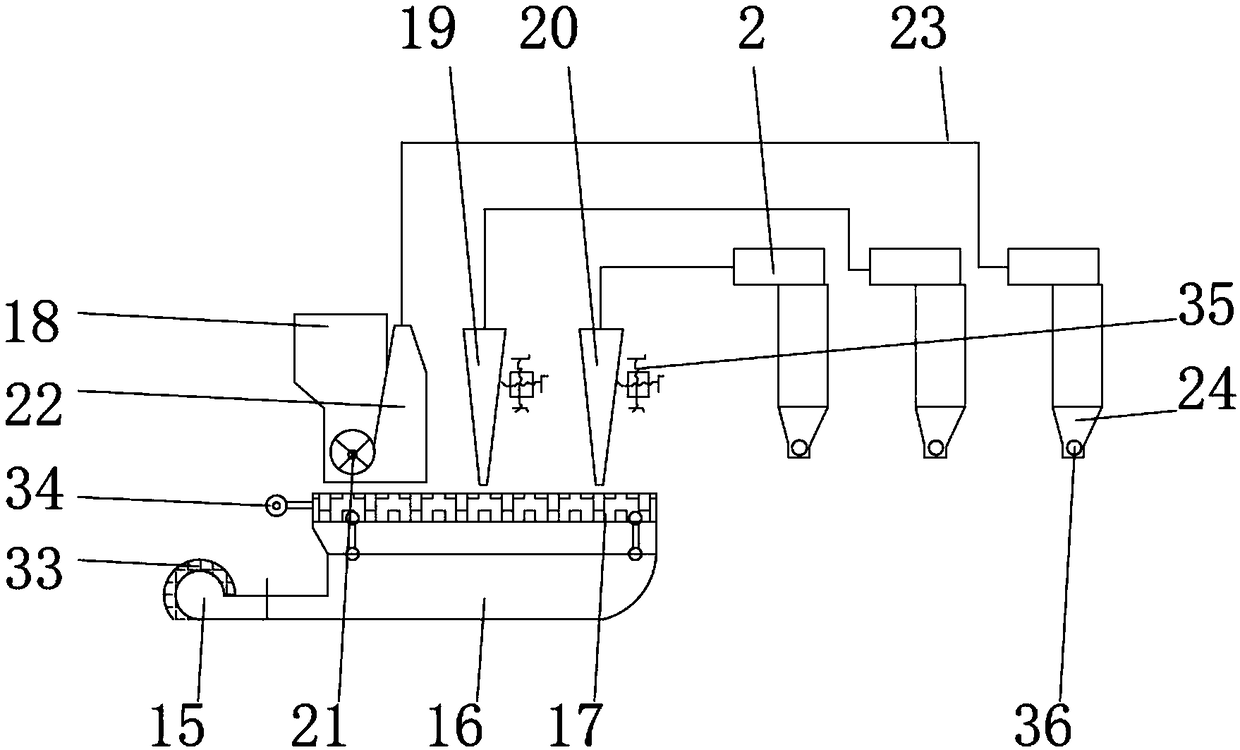

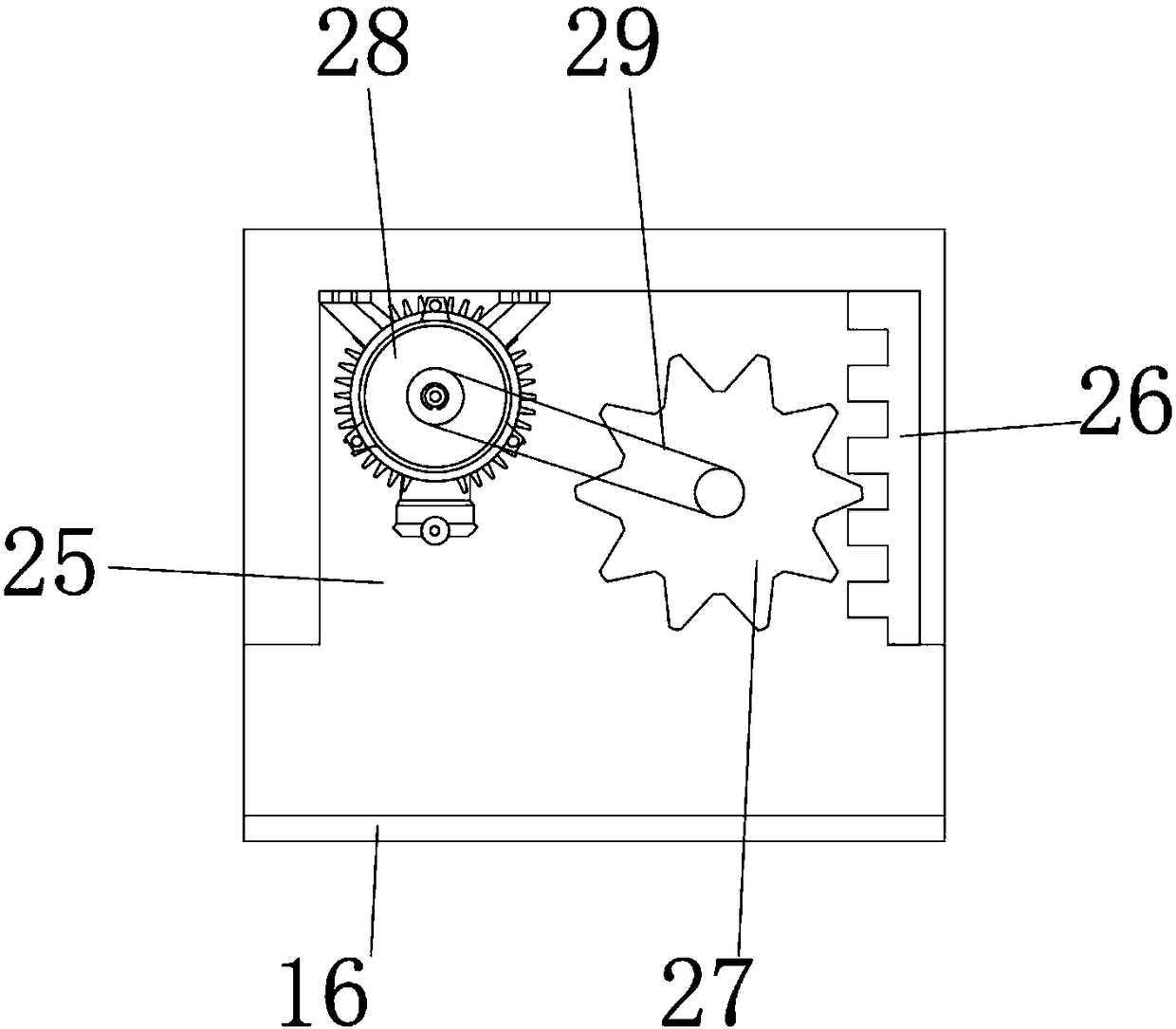

[0046] Embodiment 1: get 5kg commercially available rice dumpling skin linseed adopt as attached figure 1 The airflow sorting equipment shown classifies and screens flaxseeds, removes physical impurities and low-quality seeds, and obtains 4.57 kg of flaxseeds with plump particles and uniform appearance; the obtained flaxseeds are dried at 60°C in an electric heating blast drying oven After 45min, 4.43kg of dry flaxseed was obtained; the dried flaxseed was sent into the figure 2 In the high-throughput impact peeling machine shown, the variable speed motor controlled by the AC frequency converter is driven by variable speed, and the linear speed of the throwing tray is steplessly adjusted to obtain an appropriate impact force. Preliminary separation obtains 4.36kg of linseed husk kernel mixture; the linseed husk kernel mixture of preliminary separation is sent into image 3 In the cyclone separation system shown, the amplitude of the sieve plate is controlled to be 6mm, the vi...

Embodiment 2

[0047] Embodiment 2: get 5kg commercially available gold linseed and adopt as attached figure 1 The airflow sorting equipment shown classifies and screens flaxseeds, removes physical impurities and low-quality seeds, and obtains 4.47kg of flaxseeds with full particles and uniform appearance; the obtained flaxseeds are dried at 80°C by an electric heating blast drying oven After 30min, 4.23kg of dry flaxseed was obtained; the dried flaxseed was sent into the figure 2 In the high-throughput impact peeling machine shown, the variable speed motor controlled by the AC frequency converter is driven by variable speed, and the linear speed of the throwing tray is steplessly adjusted to obtain an appropriate impact force. Preliminary separation obtains 4.12kg of linseed husk kernel mixture; the linseed husk kernel mixture of preliminary separation is sent into image 3 In the cyclone separation system shown, the amplitude of the sieve plate is controlled to be 6 mm, the vibration fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com