Fitting furniture part piece of furniture and method for producing a plate

A technology for furniture parts and accessories, applied in the field of manufacturing panels, can solve problems such as consumption, achieve the effect of low tensile and compressive strength, and prevent expansion or dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Accessories for furniture can have different functions and properties. For example, the fitting can be designed as an adhesive pin and be designed according to the embodiments of DE 20 2008 013 067 or DE 20 2008 013 611 . Further accessories suitable for the subject matter of the present application are described in DE 202008015732, DE 202007015604, DE 202008015704, DE 202008015731 or DE 202008015722. Fittings suitable for the invention are also disclosed in DE 202009000017 and DE 202009000019. Suitable accessories are also disclosed in DE 202007015604, WO 2006 / 106131A, WO 2009 / 050239A1, WO 2009 / 059821A1.

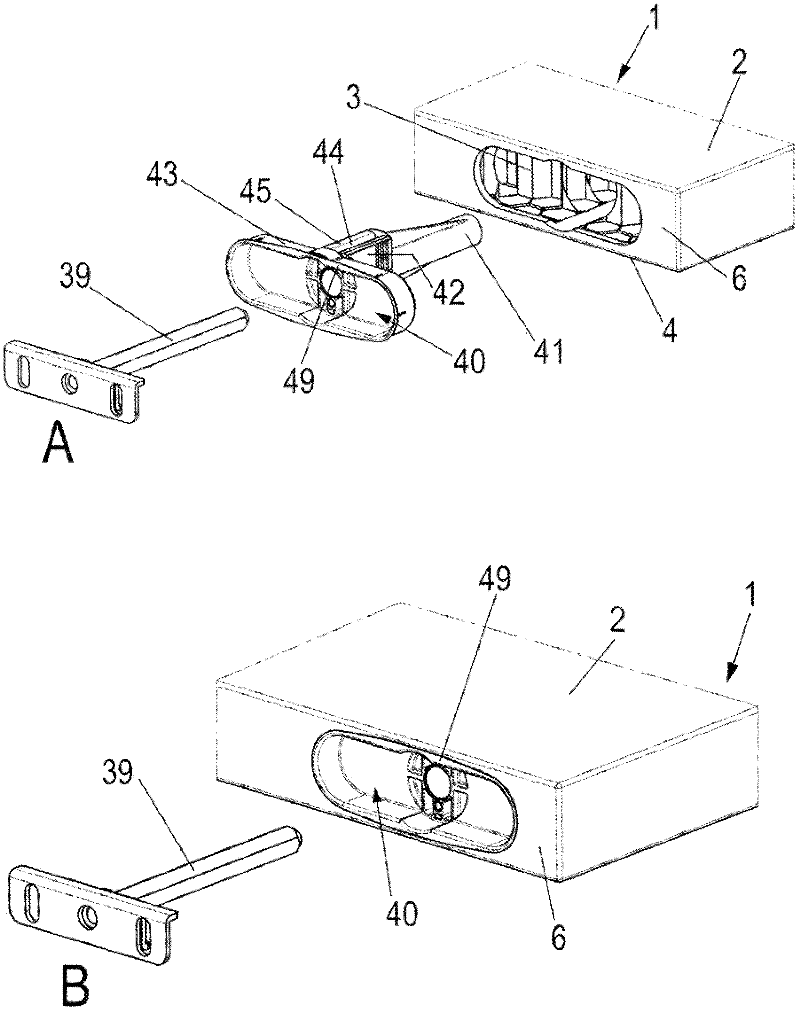

[0081] exist figure 1 A and 1B show an exemplary embodiment of a fitting 40 which has an elongated housing bowl 43 from which a projection 42 protrudes into the middle layer 3 of the lightweight construction panel 1 . A tube part 41 for fastening the fitting part 39 is also formed on the projection 42 . An adhesive chamber 44 is formed on the projection 42 , whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com