Steel rolling system provided with no-twist interchange type rolling piece guiding device

A guide device and twist-over-type technology, which is applied in the field of steel rolling systems provided with non-twist-over-type rolling stock guide devices, can solve the problems that restrict the development of the six-slice rolling process, the six-segment process is difficult to fully exert, and the consistency is very high. It is difficult to maintain stability and other problems to achieve the effect of eliminating a fault point, eliminating the fault point and ensuring the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

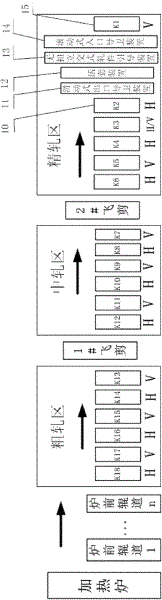

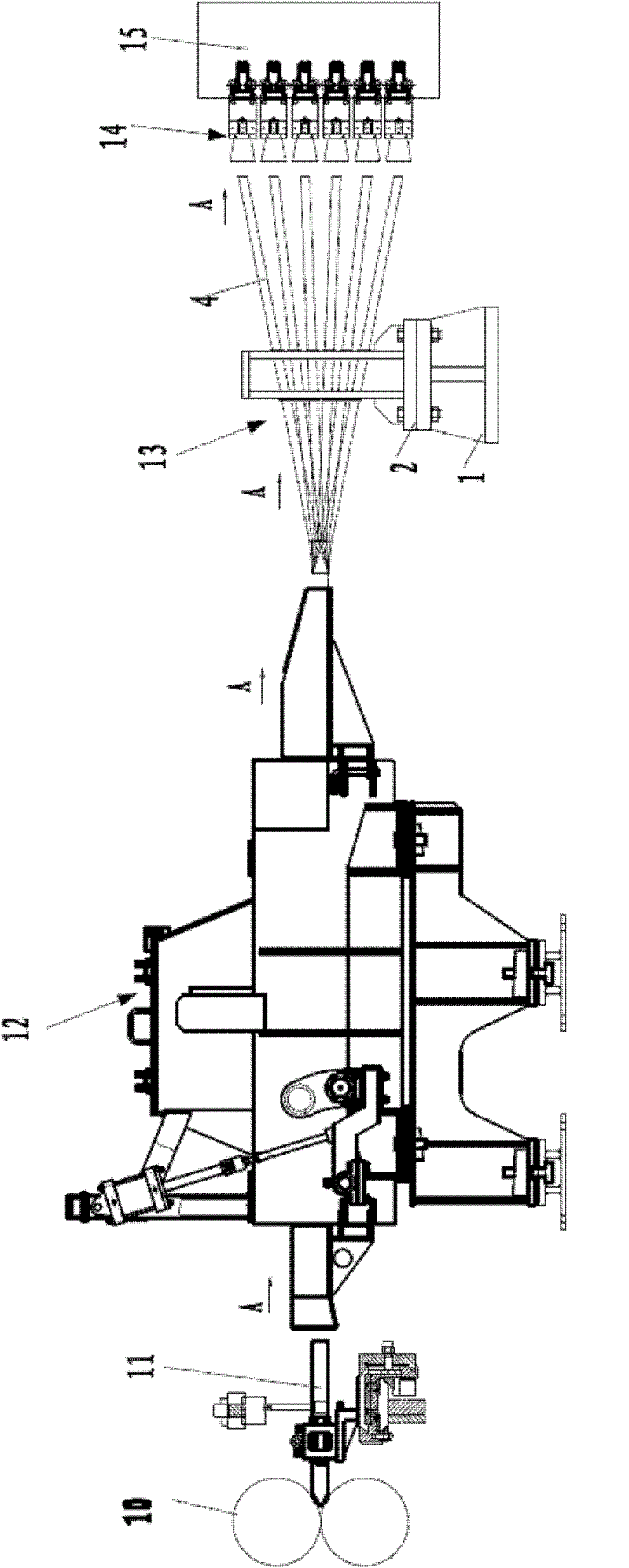

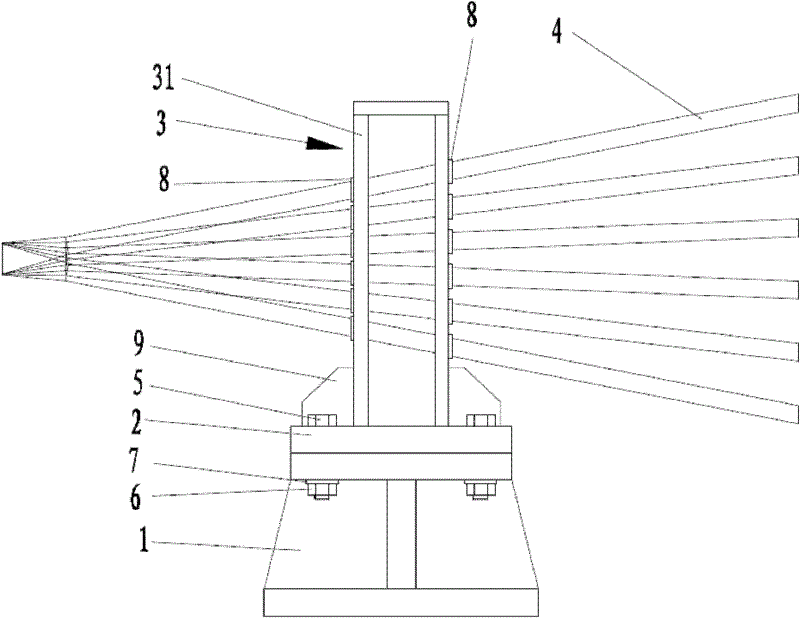

[0028] figure 1In , the direction of the arrow is the moving direction of the rolled piece. A looper device is provided between every two adjacent rolling mills in the finishing rolling area, and some looper devices are not shown in the figure. figure 1 Among them, K1~K18 represent the rolling mills, starting from the moving direction of the rolled piece in the figure, the first rolling mill is represented as K18, the second rolling mill is represented as K17..., the penultimate rolling mill 10 is represented as K2, and the last rolling mill is represented by 15 is K1; where H indicates that the rolling mill stand is a horizontal rolling mill, V indicates that the rolling mill stand is a vertical rolling mill, and H / V indicates that the rolling mill stand is a rolling mill that can be turned horizontally and vertically. figure 2 The direction of the middle arrow A is the movement direction of the rolled piece.

[0029] see Figure 1 to Figure 5 , a steel rolling system equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com