Device for collecting and releasing copper cylinder and copper ball pressure gauge

A pressure gauge and collection technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of copper pillars, copper ball pressure gauges being damaged, detached, entering the gun barrel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

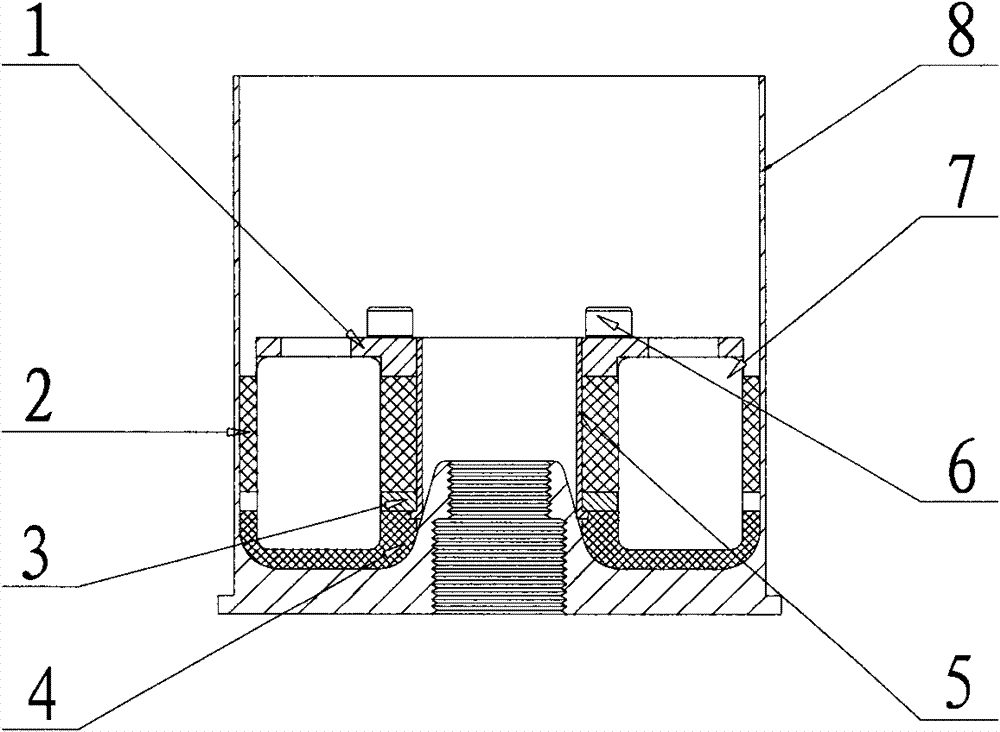

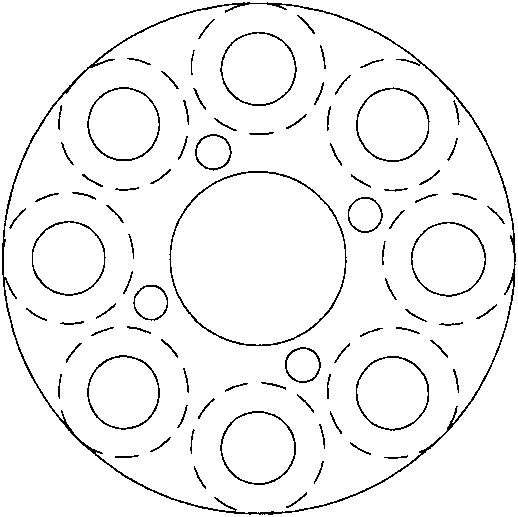

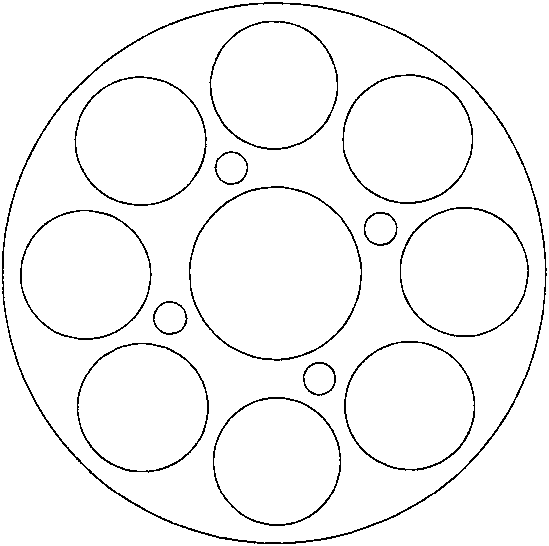

[0026] The present invention refers to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 implement.

[0027] 1. Manufacture of the present invention

[0028] The upper positioning plate, the lower positioning plate and the center pipe of the present invention are processed by steel materials, and the fastening bolts are standard parts.

[0029] The upper positioning plate is processed into a ring shape, and there are four through holes on the upper positioning plate along the circumference near the inner circumference, and 8 inverted step pressure gauge through holes are separated near the outer circumference. Part of the circumference of the end of the hole connected to the pressure gauge is tangent to the outer circumference of the upper positioning plate, and the diameter of the inverted step hole at the end connected to the pressure gauge is larger than the outer diameter of the pressure gauge to ensure that the pressure gauge The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com