Waste heat collecting and recycling method in solidification course of liquid calcium carbide

A waste heat collection and calcium carbide technology, which can be used in heating devices, other non-combustion heat generation, sustainable manufacturing/processing, etc., can solve problems such as heat energy loss, save energy, reduce production costs, and achieve the effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method for collecting and reusing waste heat in the liquid calcium carbide solidification process of the present invention is as follows:

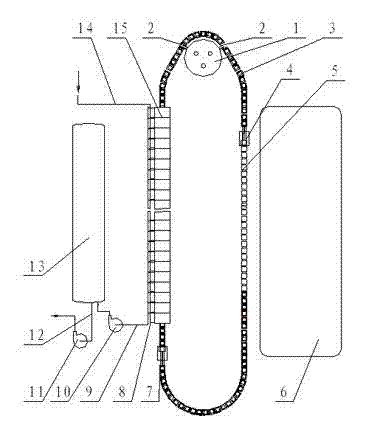

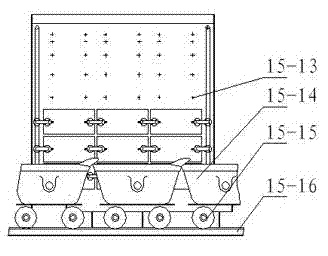

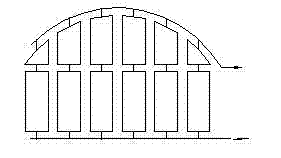

[0030] The calcium carbide furnace 1 emits high-temperature liquid calcium carbide through the furnace nozzle 2, and the calcium carbide flows into the calcium carbide pot 3. The calcium carbide pot 3 is placed in advance on the circular transport trolley 5 connected head to tail, and the circular trolley 5 is jointly dragged by the driving device 4 and 7 to walk. Every time a pot is filled with calcium carbide, the trolley moves forward one step, that is, a pot position length. The trolley driving device A4 and the trolley driving device B7 utilize hydraulic transmission to act intermittently and stop at one step, thereby realizing the effect of continuous calcium carbide pot filling. The annular transport trolley 5 carries the calcium carbide pot 3 through the waste heat collection compartment 15. After the heat is absorbed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com