Method for measuring rotating speed of main shaft of wind turbine generator system and mechanism for detecting rotating speed pulse

A spindle speed and measurement method technology, applied in the direction of linear/angular velocity measurement, velocity/acceleration/shock measurement, measuring device, etc., can solve the problems of unfavorable unit speed data acquisition accuracy and easy damage, and achieve strong anti-vibration and anti-vibration Disturbance characteristic, low cost of use, effect of smooth speed change value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

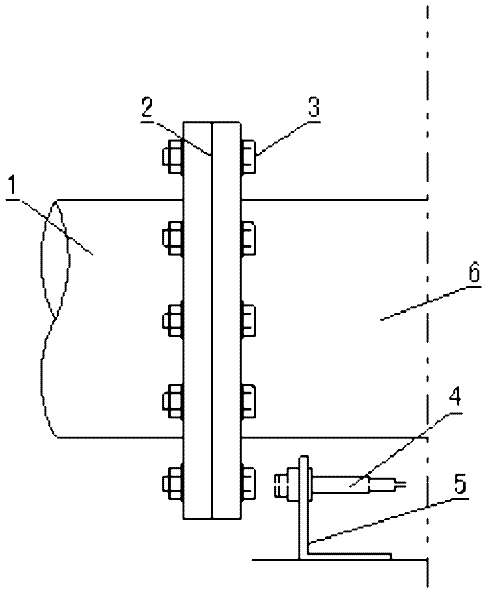

[0014] Such as figure 1 As shown, the flange plate 2 of the main shaft 1 of the wind power generating set connected to the hub mechanism 6 is provided with positioning bolts 3 at equal intervals, and the bracket 5 fixed on the nacelle or other positions supports a proximity switch 4, and the sensing head of the proximity switch is connected to the The end faces of the set bolts correspond. When the main shaft 1 rotates, adjust the distance between the sensor head of the proximity switch and the end face of the positioning bolt to obtain a relatively regular induction pulse signal. Usually, the distance between the sensor head of the proximity switch and the end face of the positioning bolt is 10-15mm. The pulse output signal of the proximity switch is connected to the high-speed counting module.

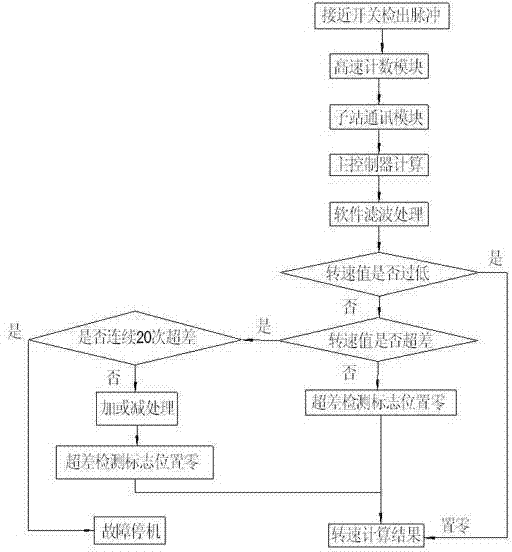

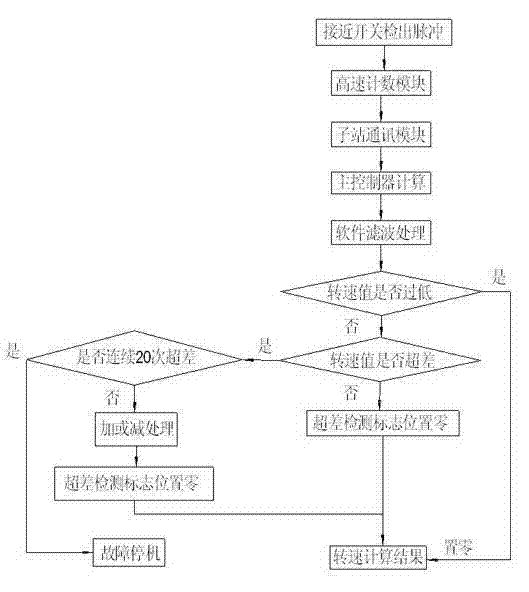

[0015] Since the number of positioning bolts is fixed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com