Rotary anti-winding device

A technology of anti-winding and rotating shaft, which is applied in the installation of cables, the arrangement of cables between relative moving parts, and electrical components, etc. It can solve the problems of complicated connection lines, improve reliability, reduce complexity, and reduce the number of wires Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

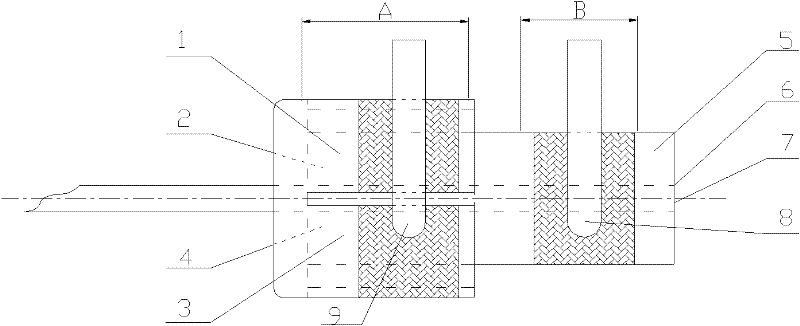

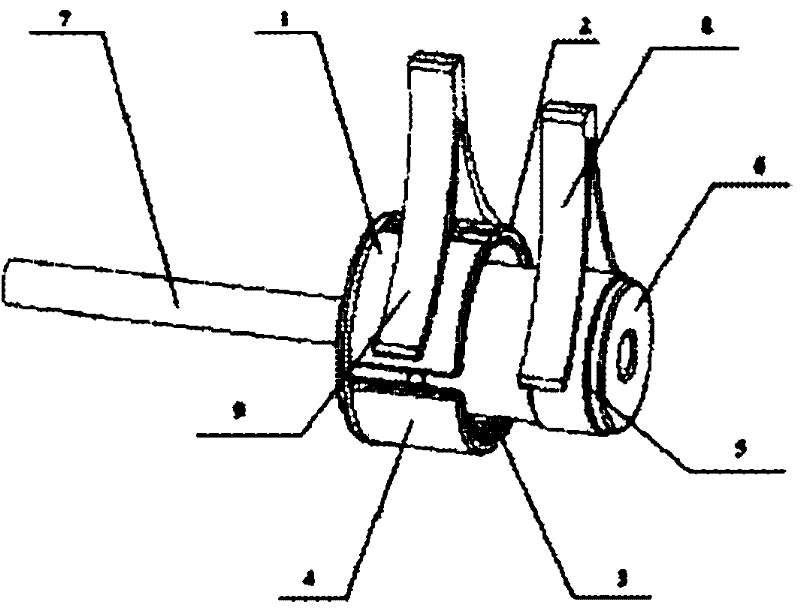

[0034] Taking the application of the anti-winding device in the cross-shaped wheel train obstacle-crossing robot as an example, the installation of this device in the robot is consistent with the description in the specific implementation. During the wiring process, because the contact surface of the anti-winding device and the shrapnel is facing upward, if image 3 shown. And the cross-shaped crossing wheel train needs signal-driven wheels that must be in contact with the ground, that is, downward, such as Figure 4 shown. The outer ring of the anti-winding device is divided into four parts 1, 2, 3 and 4, and the four ends of the cross-shaped spanning wheel train are also divided into corresponding four parts 1', 2', 3' and 4'. The connection of the line is 1 to 4', 2 to 3', to ensure that when the 1 and 2 conductive coils of the outer ring A of the anti-winding device are in contact with the shrapnel, the cruciform crosses the 3', 3', and The 4' rollers are powered on. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com