Improved corrugated plate structure

A corrugated plate and corrugated technology, applied in the field of gas-liquid (mist) separator components, can solve problems such as low droplet efficiency, easy clogging, and erosion of mist eliminators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

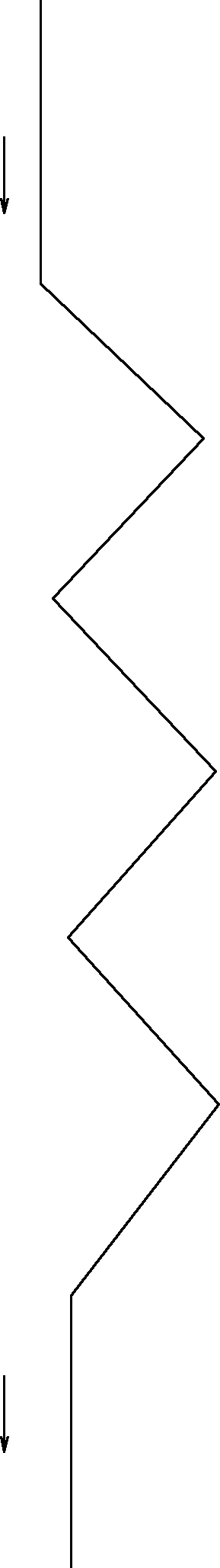

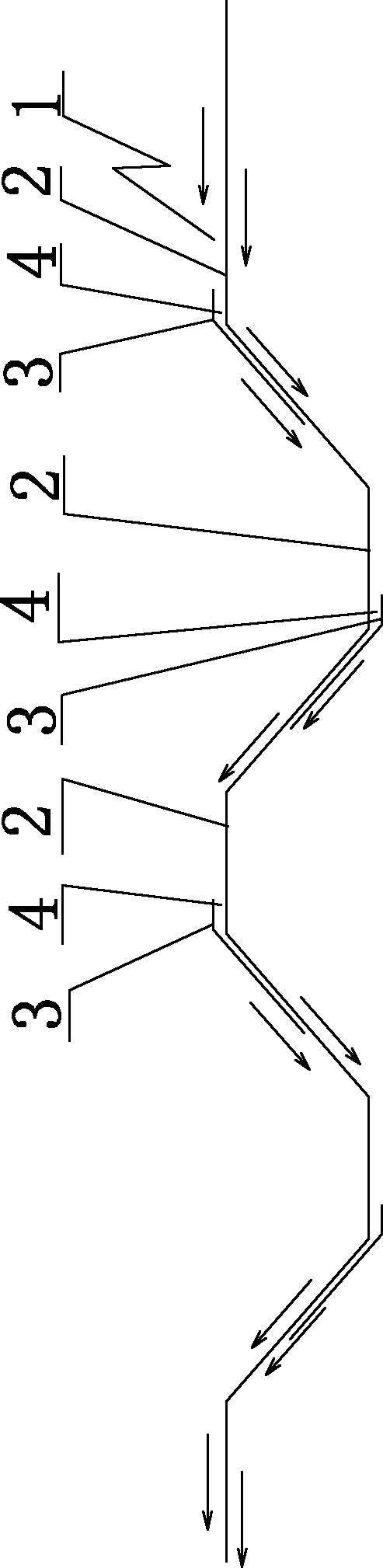

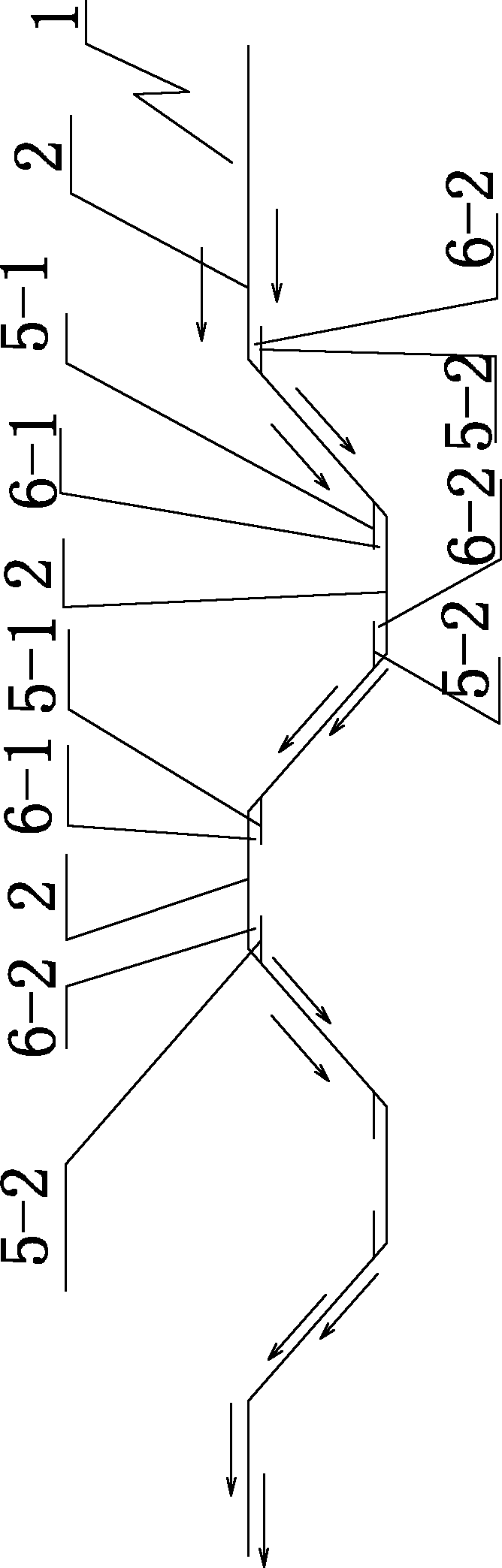

[0015] See figure 2 , image 3 , the improved corrugated plate structure of the present invention, which includes a corrugated plate body 1, the wave tip 2 of the corrugated plate body is a platform wave tip, and the included angle at the turning point of the corrugated plate body is 135°,

[0016] See figure 2 , Embodiment 1, the corrugated plate platform wave tip 2 is provided with a blade 3, the blade 3 and the corrugated plate platform wave tip 2 form an opening 4, and the opening 4 is opposite to the direction of the fluid flow channel.

[0017] See image 3 , Embodiment 2, blades 5-1, 5-2 are arranged on both sides of the wave tip 2 of the corrugated plate platform, and openings 6-1, 6-2 are formed between the blades 5-1, 5-2 and the inner side of the wave tip 2 of the corrugated plate platform .

[0018] See Figure 4 , Figure 5 , Figure 6 , the present invention also provides a mist eliminator, which includes a collection tank 7, a partition 8 and a downcome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Board width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com