Cyclone water-powder-air separator

A separation device, a cyclone-type technology, applied in the direction of the cyclone device, the device whose axial direction of the cyclone can be reversed, etc., can solve the problems that water, powder and air cannot be separated separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

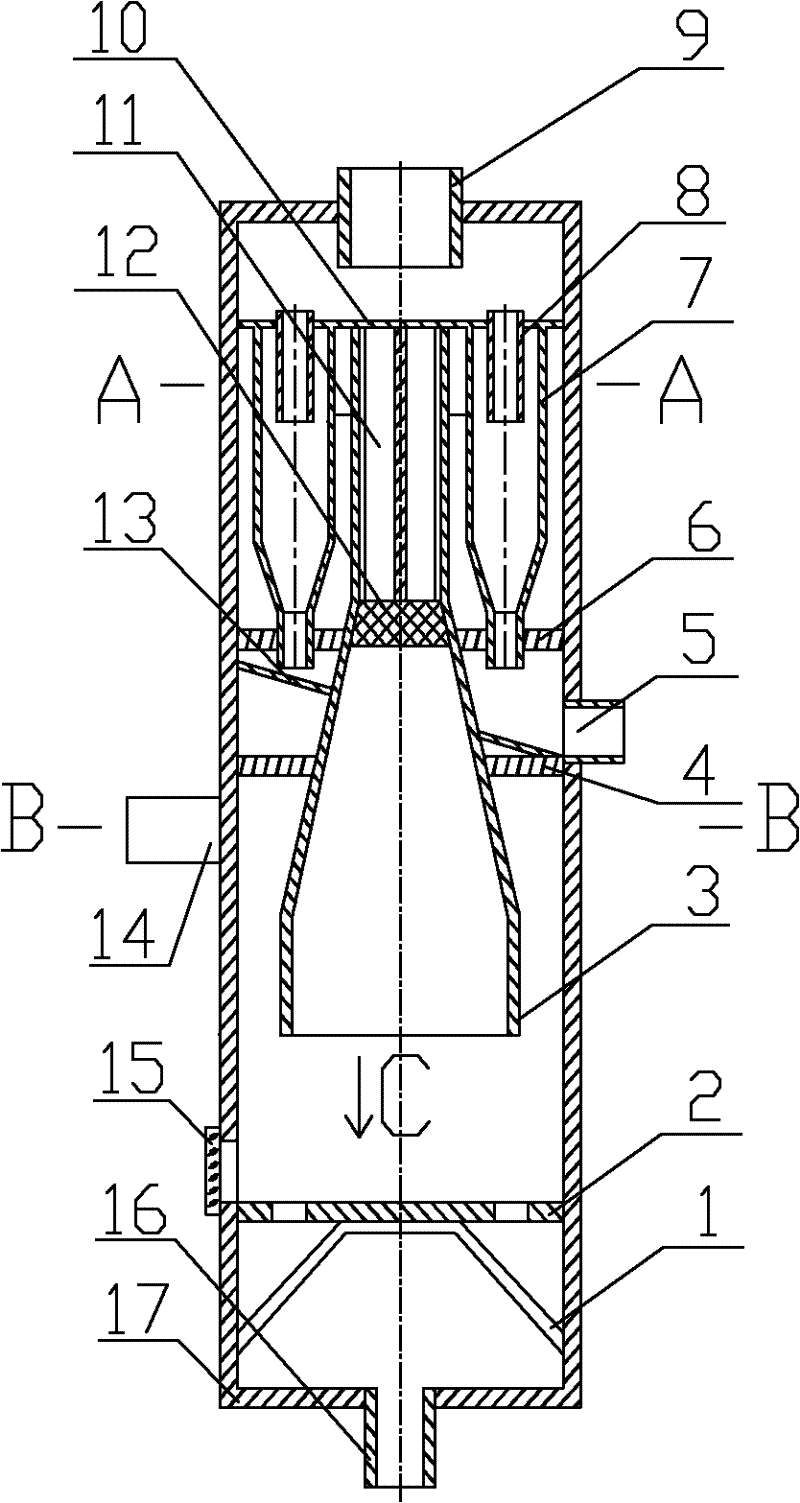

[0019] The cyclone-type water-powder gas separation device of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

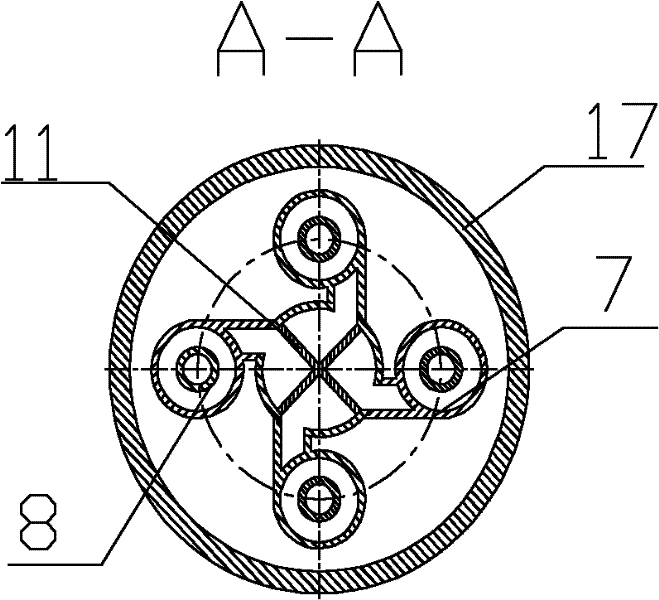

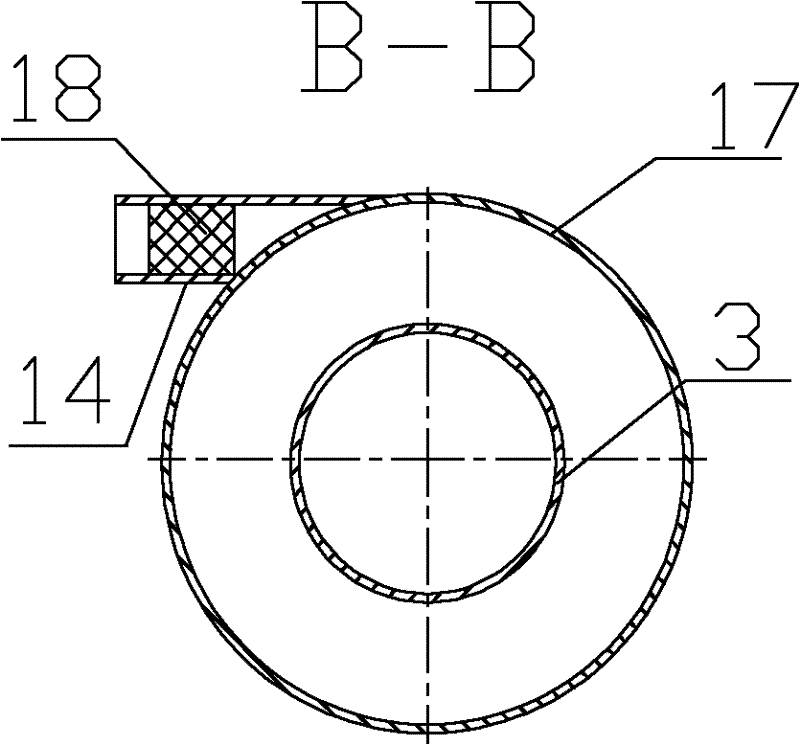

[0020] as attached figure 1 As shown, a cyclone type water powder gas separation device is composed of three parts, the first part is a cylindrical outer cylinder, the second part is cyclone water separation, and the third part is cyclone powder separation. The first part: the top of the cylindrical outer cylinder 17 is welded with a circular exhaust port 9, and the bottom is welded with a circular liquid discharge port 16; the middle of the cylinder is respectively welded with an air inlet 14 and an arc-shaped collecting plate 13 And the powder outlet 5. Among them, the air inlet 14 is welded on the lower side of the lower partition 4 along the tangential position of the cylindrical outer cylinder 17; the second part: the cyclone water separator is mainly composed of the inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com