Bearing dismounting device

A bearing dismounting device and splint technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of poor versatility of the expansion puller, easy to pull off the inner ring of the bearing, damage to the bearing, etc. Accuracy and service life, the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

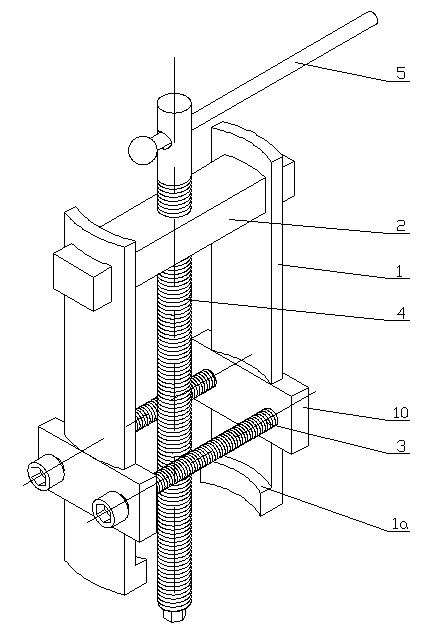

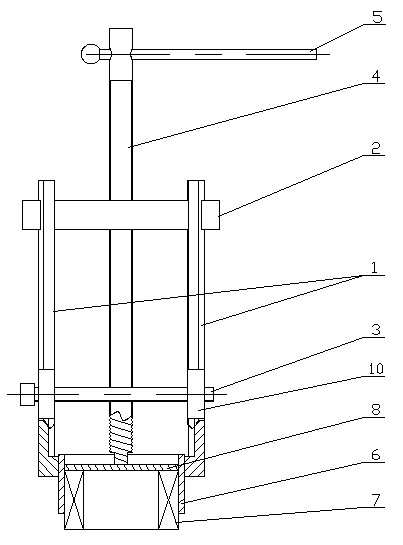

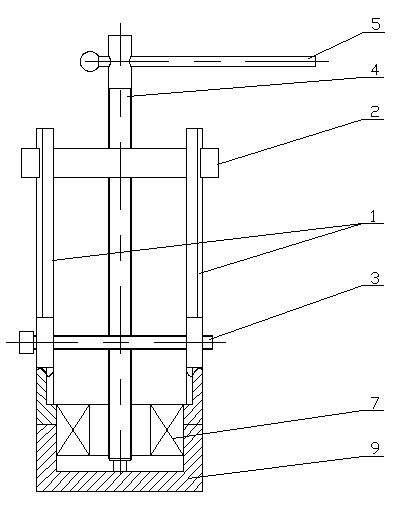

[0019] Such as figure 1 As shown, the present invention is made of parts such as splint 1, beam 2, fastener 3, push rod 4, rocker arm 5 and positioning block 10, and two splints 1 are arranged in the mode of left and right symmetry, and the upper end of these two splints 1 It is fixedly connected by the same crossbeam 2 that passes through. A clamping boss 1a is integrally formed on the opposite surfaces of the lower ends of the two splints 1. The opposite surfaces of the clamping bosses 1a at the lower ends of the two splints 1 are circular arc surfaces, and the left and right two clamping bosses 1a The arc faces are on the same circumference.

[0020] from figure 1 It can be seen from the figure that positioning blocks 10 are fixedly worn on the lower parts of the two splints 1, the positioning blocks 10 on the left and right sides are symmetrically distributed, and fasteners 3 are connected between the positioning blocks 10 on the left and right sides. Part 3 is preferab...

Embodiment 2

[0026] refer to figure 1 , In this embodiment, the upper ends of the two splints 1 and the beam 2 are connected by an adjustable structure. For example, the upper end of splint 1 is looped on beam 2 and positioned by screws. In this way, by adjusting the positions of the two splints 1 on the beam 2, the distance between the two clamping bosses 1a can be adjusted to meet the needs of dismounting bearings of different specifications. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com