Belt conveyor sweeper

A technology for belt conveyors and cleaners, which is applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc. It can solve problems such as inconvenient installation, maintenance and replacement, unstable operation of cleaners, and deformation of scrapers of cleaners. Achieve the effect of stable and reliable fixing method, easy cleaning of adhered materials, and stable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the specific embodiments and accompanying drawings. The specific embodiments and accompanying drawings are further descriptions of the principles of the present invention, and do not limit the present invention in any way. The same or similar technologies as the present invention do not exceed the protection scope of the present invention. .

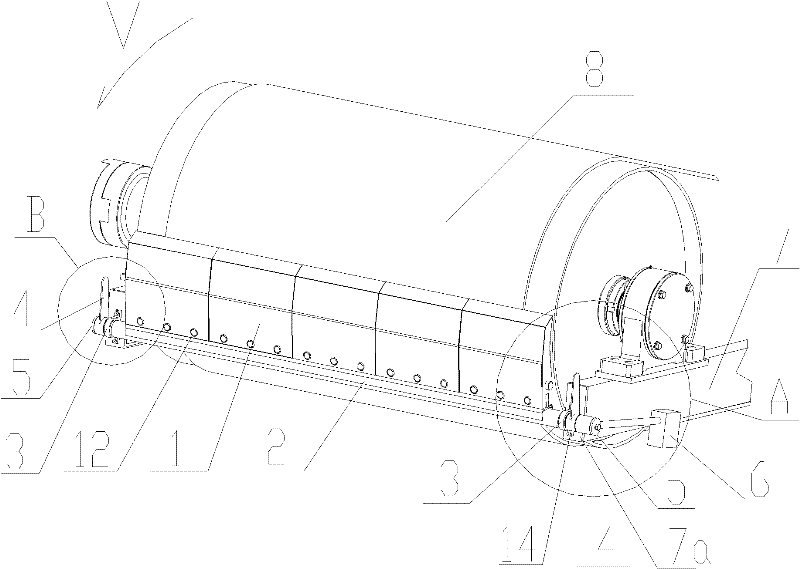

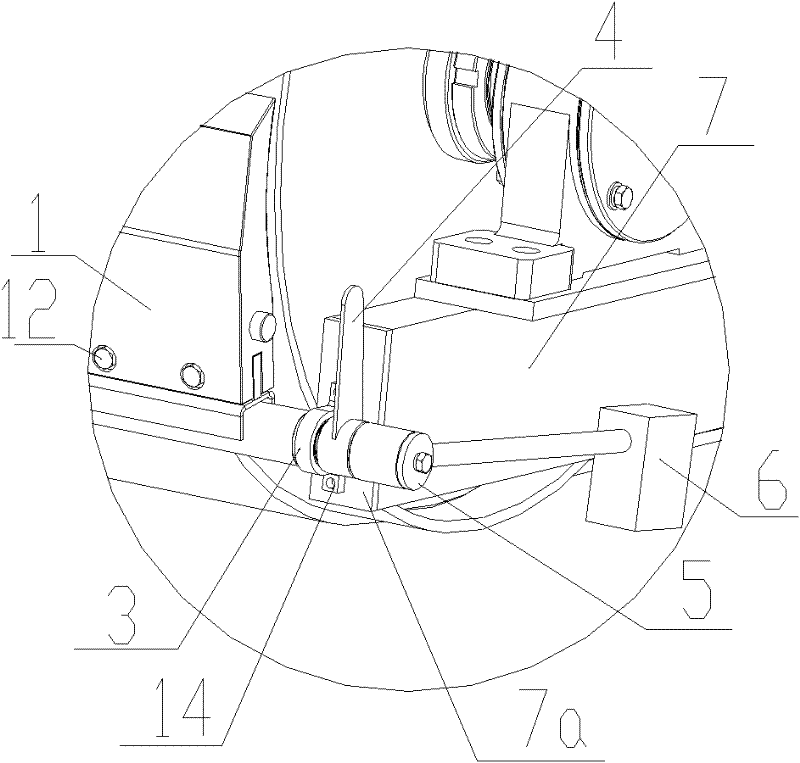

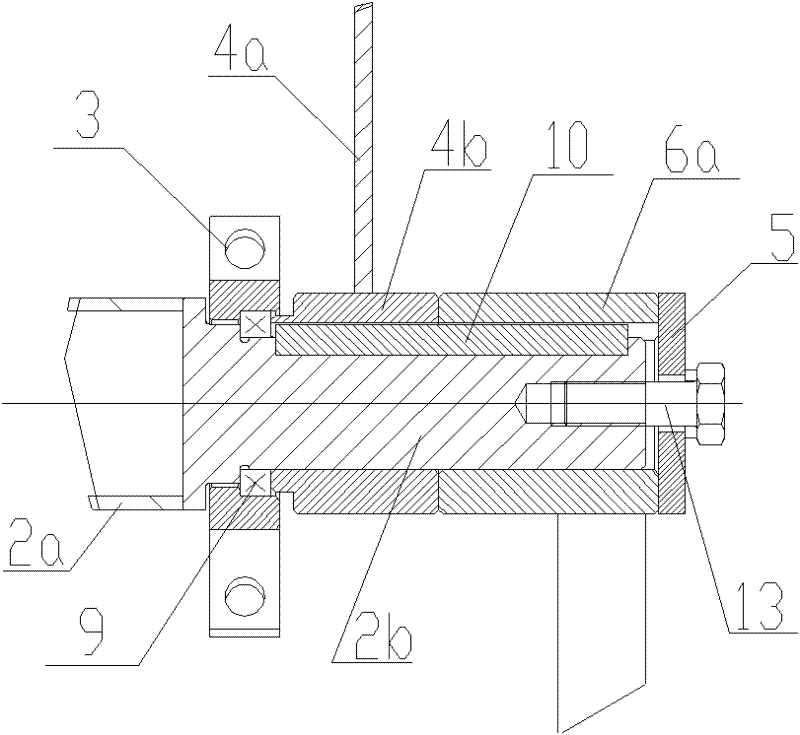

[0039] Belt conveyor cleaner, including scraper, scraper connection mechanism and scraper adjustment mechanism, scraper 1 is set along the arc surface of the belt, scraper 1 has an arc 1e matching with the arc surface of the belt, scraper 1 end 1f Contact with the belt; the scraper connecting mechanism has a shaft 2, the scraper 1 is axially connected and fixed along the shaft 2, and the two ends of the shaft 2 are hinged with the side beam 7 of the belt conveyor; the scraper adjustment mechanism has a lever 6b, and one end of the lever 6b has a matching The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com