Method for extracting ursolic acid with Folium Forsythia as raw material

A technology of ursolic acid and forsythia leaves, applied in the direction of steroids, organic chemistry, etc., can solve problems such as unsuitability for large-scale industrial production, hazards to production equipment and production personnel, waste of forsythia leaves, etc., to achieve reduction in dosage and Effects of energy consumption, production cost reduction, and reduction in the number of treatments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

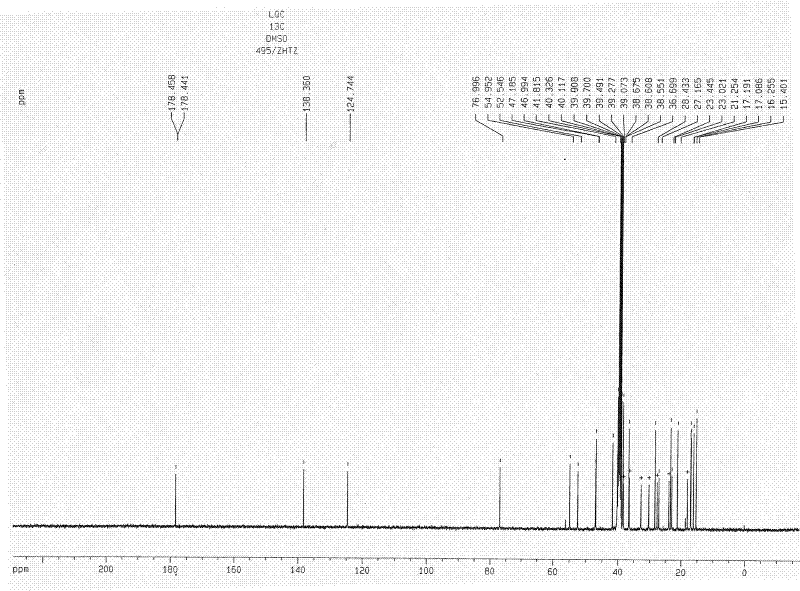

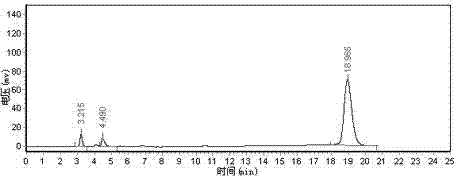

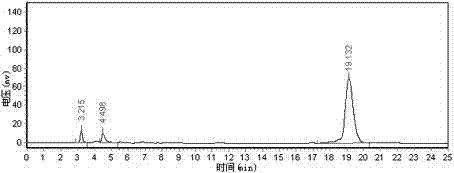

Image

Examples

Embodiment 1

[0038] A method for extracting ursolic acid using forsythia leaves as a raw material, comprising the steps of:

[0039]①Coarse extraction: Mix 5kg of forsythia leaves and 50kg of water and cook at 80°C for 1.5 hours (extraction 2 times). time, each extraction for 1 hour, the amount of ethanol added in the first extraction was 5 times of the weight of the residue, and the amount of ethanol added in the second extraction was 3 times of the weight of the residue), the alcohol extracts combined twice were filtered out The residue and the filtrate were left to cool to room temperature naturally, and the precipitate (ie crude ursolic acid) and the supernatant were obtained from the filtrate, and the precipitate and the supernatant were separated. After precipitation and drying, 164 g of crude ursolic acid was obtained with a purity of 41.5%. The supernatant can be reused as an extraction solvent for new raw materials.

[0040] 2. Refining: Decolorize the gained ursolic acid crude ...

Embodiment 2

[0042] A method for extracting ursolic acid using forsythia leaves as a raw material, comprising the steps of:

[0043] ①Coarse extraction: mix 3.5kg of forsythia leaves and 28kg of water and cook at 90°C for 1 hour (extraction twice). 2 times, each extraction for 1 hour, the amount of ethanol added during the first extraction was 8 times the weight of the residue, and the amount of ethanol added during the second extraction was 4 times the weight of the residue), the alcohol extracts were combined twice, filtered Remove the residue, let the filtrate stand and cool down to room temperature naturally, and obtain the precipitate (ie crude ursolic acid) and supernatant separated from the filtrate, and separate the precipitate and supernatant. After precipitation and drying, 112 g of crude ursolic acid was obtained with a purity of 40.8%. The supernatant can be reused as an extraction solvent for new raw materials.

[0044] ② Refining: The obtained crude ursolic acid was decolor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com