Progressive shielding booster-type grouting and reinforcing technology for baseboard

A technology of grouting reinforcement and floor plate, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of collapsed hole, poor hole quality of floor drilling, sludge, etc., to improve integrity and facilitate maintenance. , the effect of reducing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

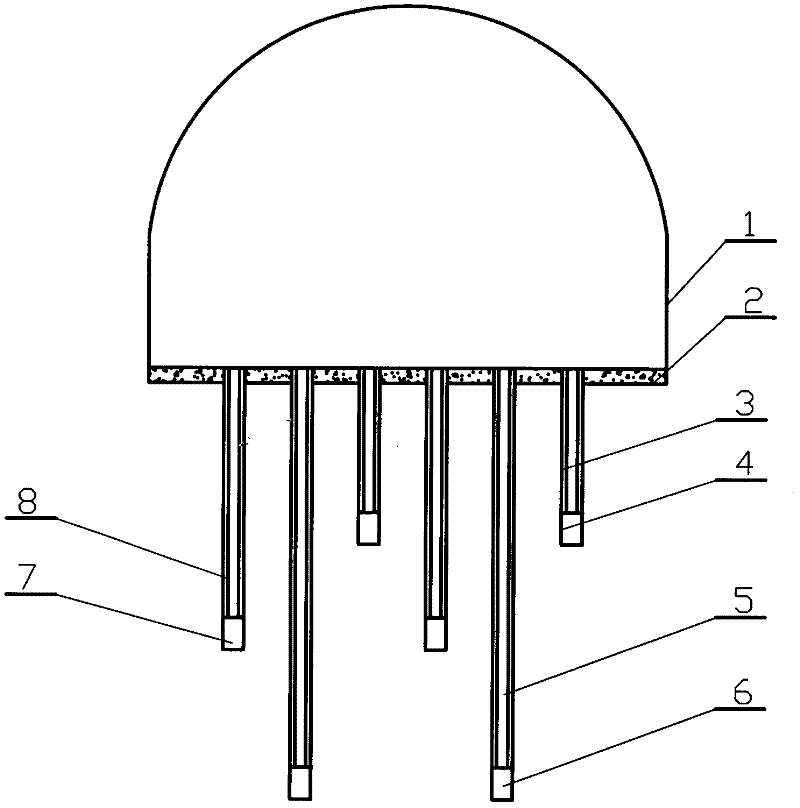

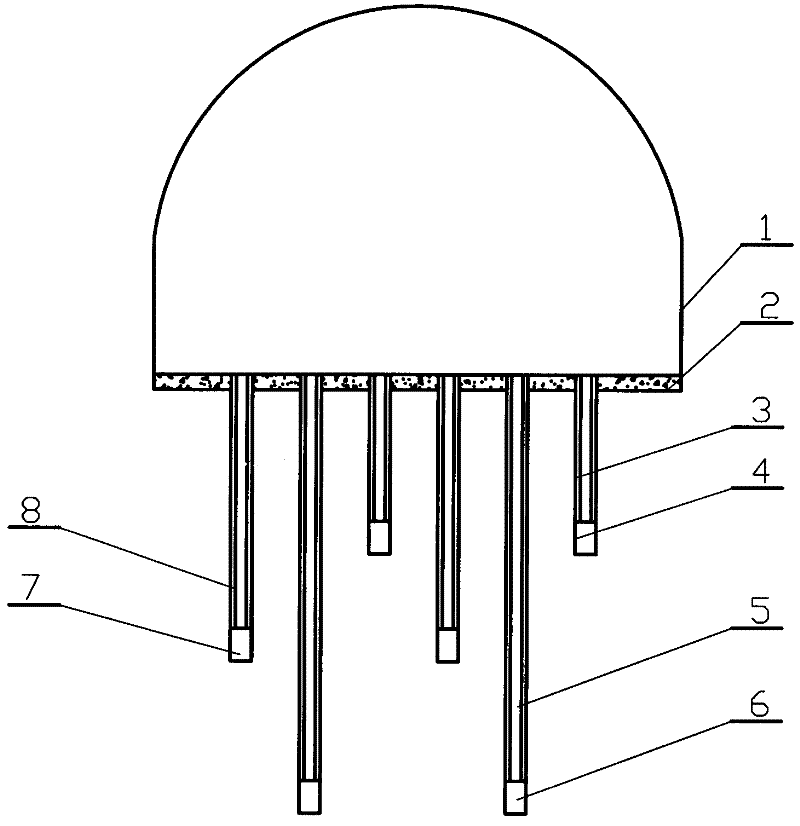

[0016] In the accompanying drawings, the operation steps of this kind of base plate progressive cover pressurized grouting reinforcement technology are as follows:

[0017] ①Construction floor: construct a 0.2m thick concrete floor (2) on the floor of the roadway (1) to provide a grout-stop layer for the bottom plate of the roadway (1);

[0018] ②Shallow hole grouting: After the concrete floor (2) is solidified, shallow grouting holes (4) in the bottom plate of the roadway (1) with a depth of 1.5-2.5m are constructed, and the spacing between the holes is 1.5m-3.0m. Then install a shallow hole grouting pipe (3) in the hole, and seal the hole with rapid hardening cement, a hole sealer, etc. After the hole sealing is completed, it is grouted. When the grouting pressure reaches 1.0-2.0Mpa, the pressure is stabilized Stop grouting after 3 to 5 minutes;

[0019] ③Medium and deep hole grouting: After the shallow hole grouting is completed, the middle and deep grouting holes (7) with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com