Method for replacing ground potentials of tension insulator string in vertical dual-string arrangement

A technology of vertical arrangement and insulator strings, which is applied in the direction of overhead lines/cable equipment, etc., and can solve problems such as the difficulty in completing the ground potential replacement operation of double strings of vertically arranged insulator strings for strain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

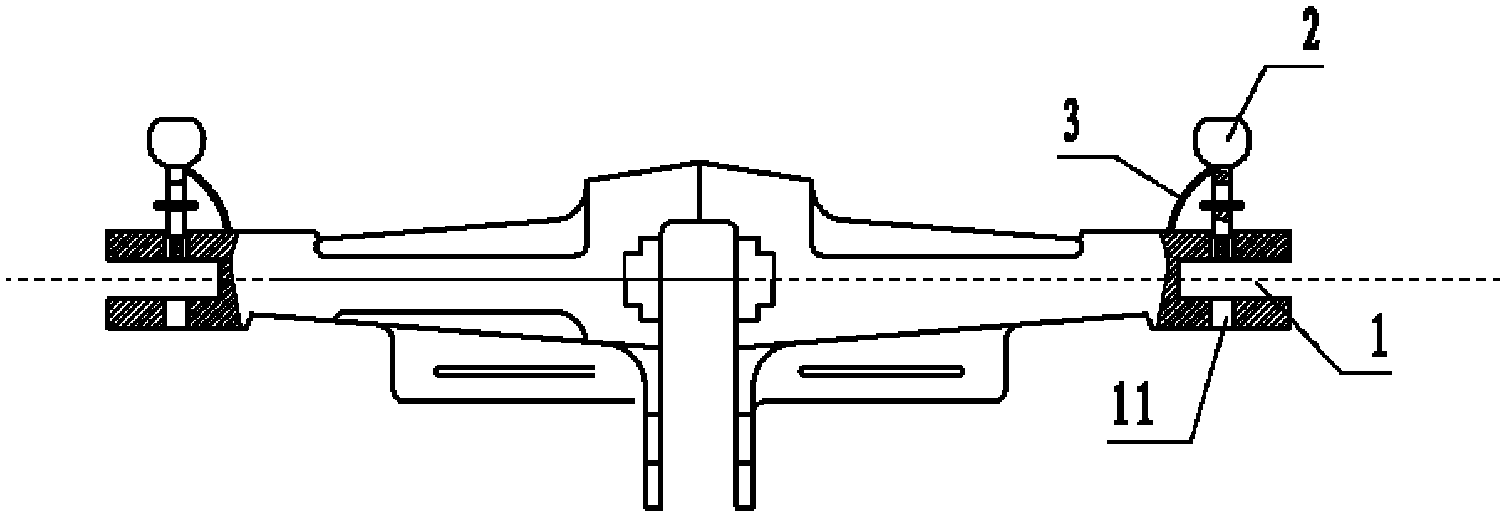

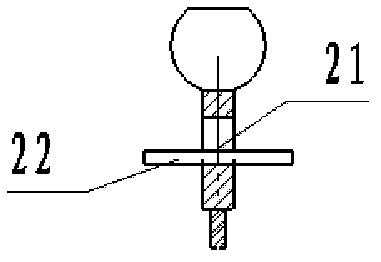

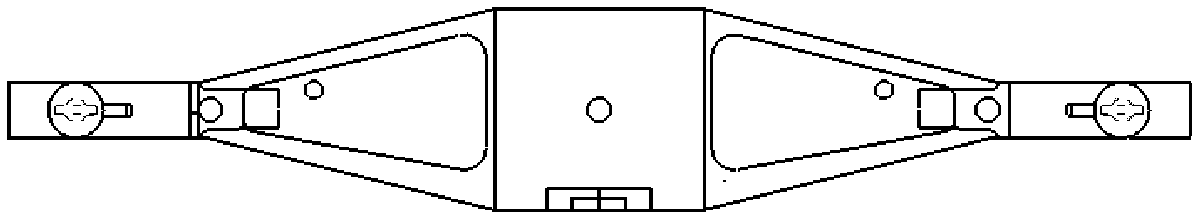

[0043] A method for replacing the ground potential of tension-resistant double-string vertically arranged insulator strings, which includes a front card that can realize long-distance indirect installation and locking, an insulating pull plate used in conjunction with the front card with a locking device, and a fastening screw rod , back card;

[0044] First set the locking device on the front card to the unlocked state, then install the front card independently at the designated position, the operator snaps the insulating pull plate into the front card through the operating rod, and the operator snaps the insulating pull plate into the front card through the operating rod The front card, and operate the insulating pull plate to adjust to the required length, and then lock the locking device on the front card to complete the installation of the left and right insulating pull plates, and then install the rear card on the side triangle of the transom. After the screw rod of the ...

Embodiment 2

[0048] A method for replacing the ground potential of tension-resistant double-string vertically arranged insulator strings, which includes a front card that can realize long-distance indirect installation and locking, an insulating pull plate used in conjunction with the front card with a locking device, and a fastening screw rod , back card;

[0049] First set the locking device on the front card to the unlocked state, then install the front card independently at the designated position, the operator snaps the insulating pull rod into the front card through the operating lever, and the operator snaps the insulating pull rod into the front card through the operating rod The front card is adjusted to the required length by operating the insulating rod, and then the locking device on the front card is locked to complete the installation of the left and right insulating pull plates. After the screw rod of the rear card is connected with the insulating pull rod, tighten the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com