Water-cooling cutting motor installed in rocker of low seam mining machine

A technology for cutting motors and shearers, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of occupying volume, size limitation of electromagnetic components, and difficulty in increasing motor power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

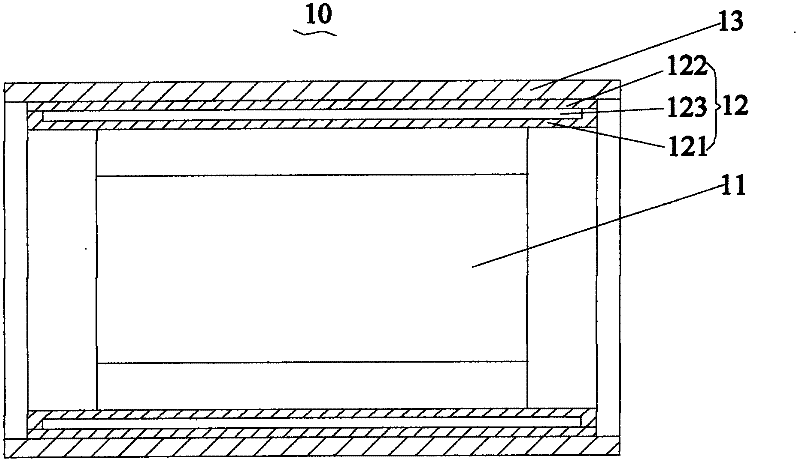

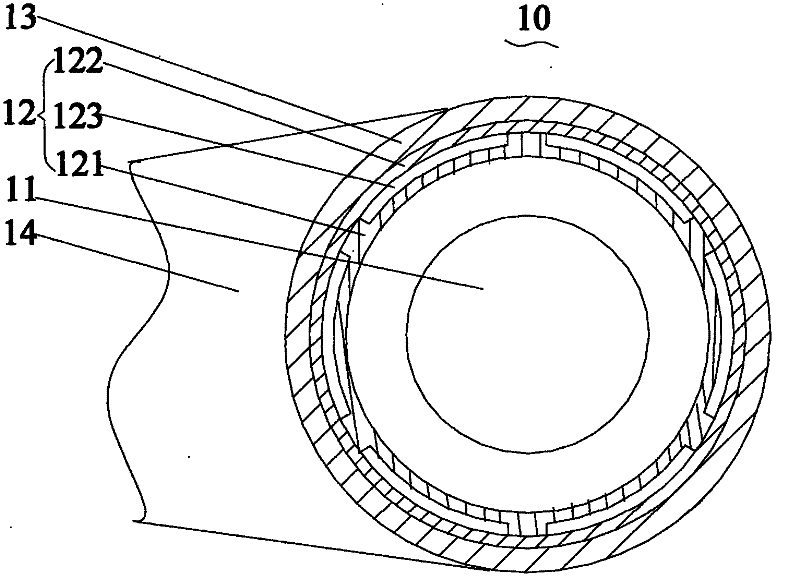

[0025] After the water-cooled cutting motor installed in the rocker arm of the thin coal seam shearer in the present invention is installed in the rocker arm of the thin coal seam shearer, the outer water jacket is replaced by the rocker arm shell of the thin coal seam shearer, and its electromagnetic components protect The shell can be assembled with the rocker arm shell of the thin coal seam shearer to form a relatively sealed cooling water channel.

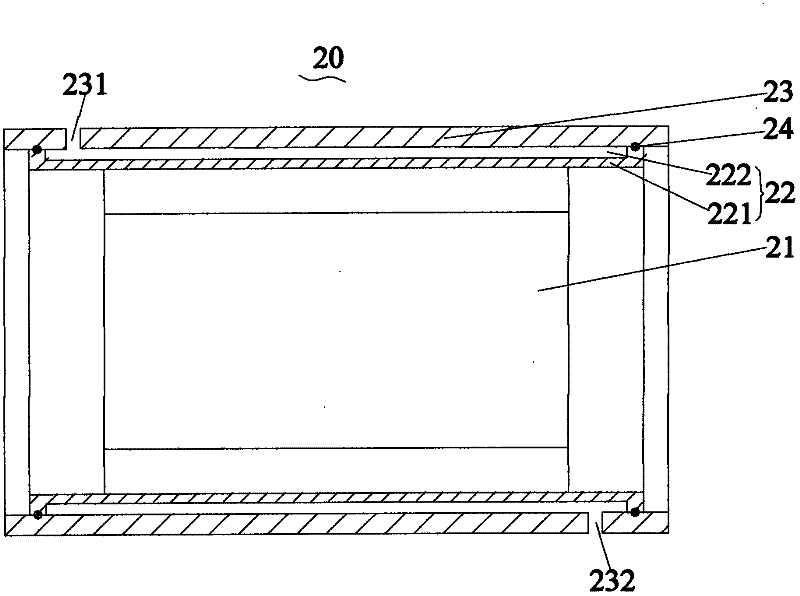

[0026] Specifically, please also refer to image 3 , Figure 4 , the water-cooled cutting motor 20 installed in the rocker arm of the thin coal seam shearer includes an electromagnetic component 21 and a protective shell 22 for the electromagnetic component. Among them, the electromagnetic component 21 includes a stator and a rotor; the electromagnetic component protective shell 22 includes components such as a water-cooled machine base, an end cover, and a junction box.

[0027] The electromagnetic component protection case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com