Sodium phosphate composition

A technology of sodium phosphate salt and composition, applied in the field of sodium phosphate salt composition, can solve problems such as inconvenience to carry, hidden safety hazards, inconvenience to use and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

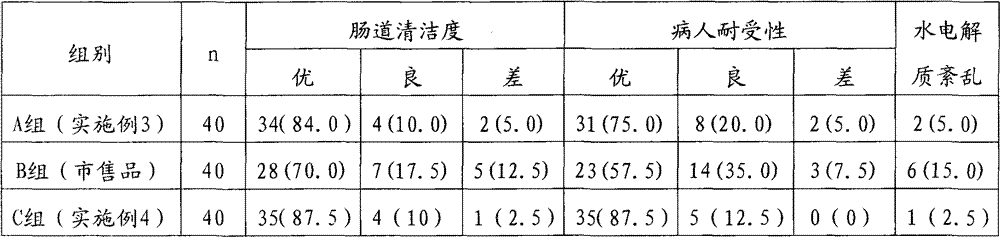

Examples

Embodiment 1

[0020] Sodium Phosphate Powder

[0021] 1. Prescription:

[0022] Sodium dihydrogen phosphate (in the form of monohydrate 21.6kg) 18.8kg

[0023] Disodium hydrogen phosphate (in anhydrous form) 4.3kg

[0024] Simethicone 0.15kg

[0025] Silica 0.1kg

[0026] A total of 1000 bags were made

[0027] 2. Process steps:

[0028] (1) Initial mixing: take the prescribed amount of sodium dihydrogen phosphate, disodium hydrogen phosphate, simethicone, and silicon dioxide, and place them in a mixer for initial mixing for 3 minutes;

[0029] (2) Powder sifting: grind powder in a universal pulverizer, pass through an 80-mesh sieve, and obtain mixed powder;

[0030] (3) Total mixing: the mixed powder is mixed in a mixer for 3 minutes, fully mixed evenly, and sealed for storage;

[0031] (4) Bagging.

[0032] 3. Usage and dosage

[0033] Oral administration: 52.3g (2 bags) for cleaning the intestinal tract once. Take 26g the night before surgery...

Embodiment 2

[0035] Sodium Phosphate Powder

[0036] 1. Prescription:

[0037] Sodium dihydrogen phosphate (in the form of monohydrate 21.6kg) 18.8kg

[0038] Disodium hydrogen phosphate (in anhydrous form) 4.3kg

[0039] Simethicone 0.15kg

[0040] Glucose 2.35kg

[0041] Silica 0.1kg

[0042] A total of 1000 bags were made

[0043] 2. Process steps:

[0044] (1) Preliminary mixing: Weigh the prescribed amount of sodium dihydrogen phosphate, disodium hydrogen phosphate, simethicone, silicon dioxide, and glucose, and place them in a mixer for initial mixing for 3 minutes;

[0045] (2) Powder sifting: grind powder in a universal pulverizer, pass through an 80-mesh sieve, and obtain mixed powder;

[0046] (3) Total mixing: the mixed powder is mixed in a mixer for 3 minutes, fully mixed evenly, and sealed for storage;

[0047] (4) Bagging.

[0048] 3. Usage and dosage

[0049] Oral administration: 57g (2 bags) for cleaning the intestinal tract once...

Embodiment 3

[0051] Sodium Phosphate Powder

[0052] 1. Prescription:

[0053] Disodium hydrogen phosphate (in anhydrous form) 4.3kg

[0054] Sodium dihydrogen phosphate (in the form of monohydrate 21.6kg) 18.8kg

[0055] Aspartame 0.2kg

[0056] Glycerin 0.05kg

[0057] Lemon essence 0.04kg

[0058] Simethicone 0.15kg

[0059] Silica 0.5kg

[0060] A total of 1000 bags were made

[0061] 2. Process steps:

[0062] (1) Initial mixing: Weigh the prescribed amount of sodium dihydrogen phosphate, disodium hydrogen phosphate, simethicone, and glycerin, and place them in a mixer for initial mixing for 3 minutes;

[0063] (2) Powder sifting: grind powder in a universal pulverizer, pass through an 80-mesh sieve, and obtain mixed powder;

[0064] (3) Total mixing: add the prescribed amount of aspartame, lemon essence, and silicon dioxide to the mixed powder, mix in the mixer for 3 minutes, fully mix evenly, and seal and store;

[0065] (4) Bagging.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com