Rapid die clamping device for die casting machine

A clamping device and die-casting machine technology, applied in the field of die-casting machines, can solve the problems of increasing the scrap rate, time-consuming, damage to the mold, etc., and achieve the effect of preventing the mold from loosening and shifting, and making the connection safe and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

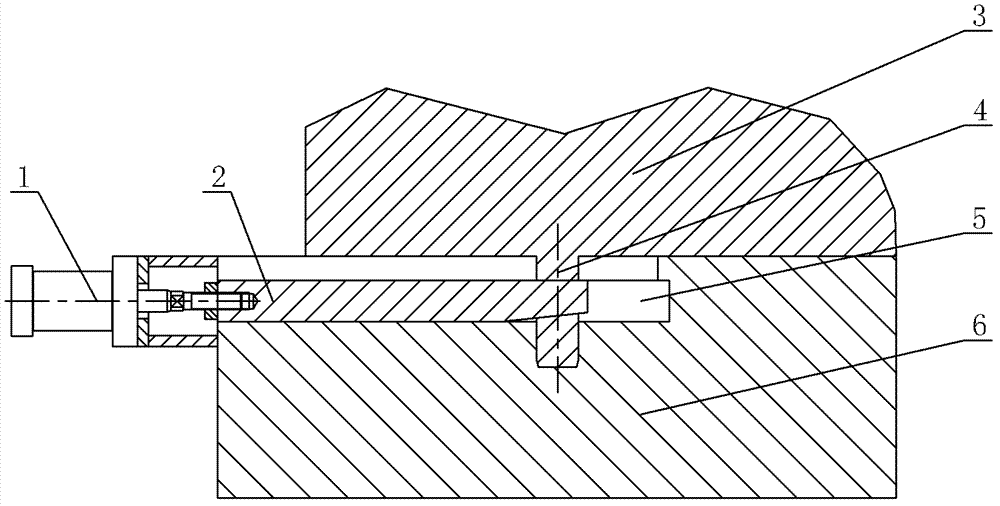

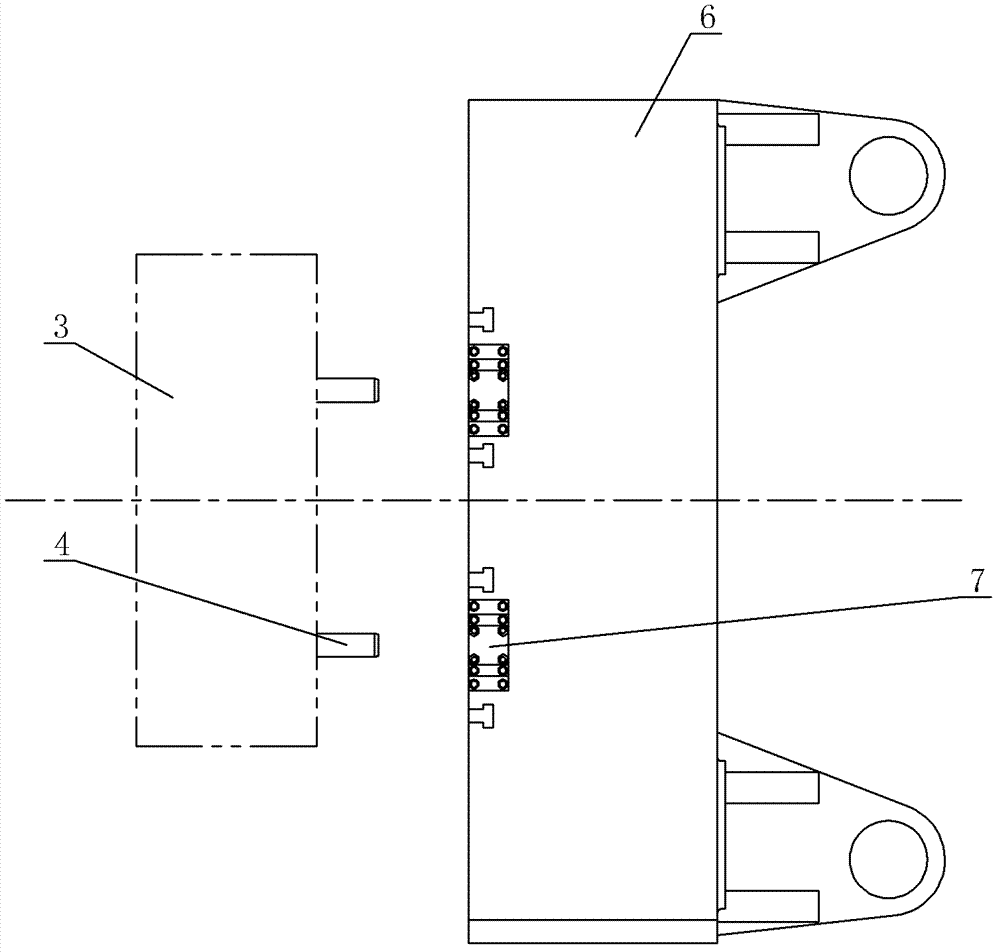

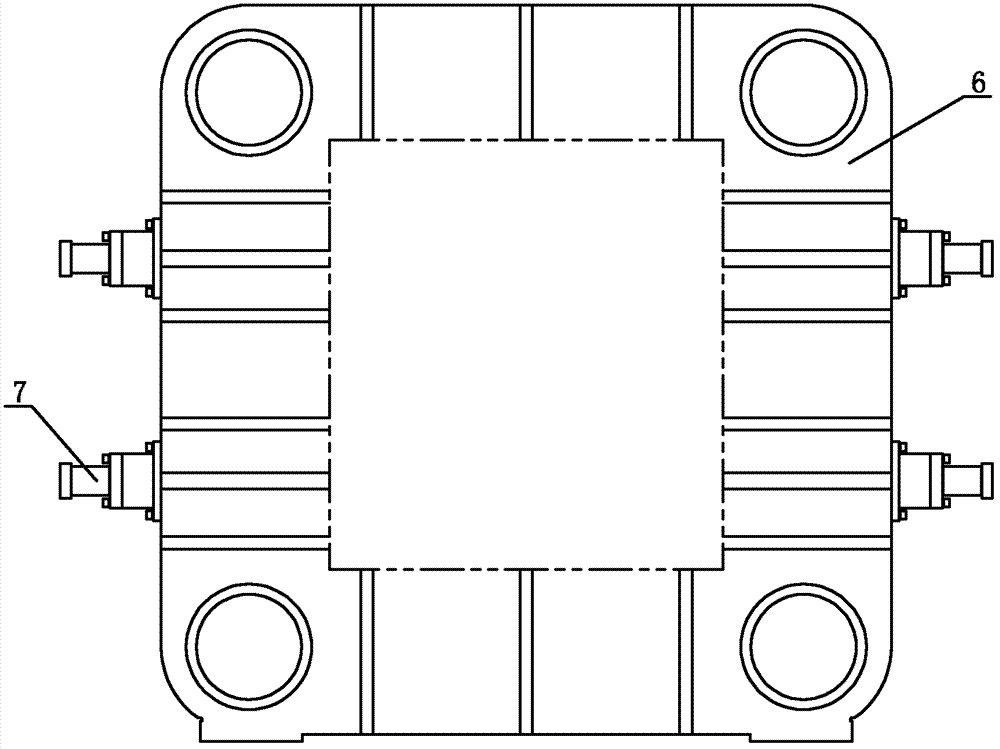

[0017] see Figure 1-Figure 3 , the mold quick clamping device of the die casting machine includes a template 6 arranged on the die casting machine, and a quick clamping mechanism 7 capable of clamping the mold 3 is installed on the template 6 .

[0018] The quick clamping mechanism 7 includes a driving element 1 installed on the side wall of the template 6 , a channel 5 is provided on the template 6 corresponding to the driving element 1 , and a locking link 2 is slidably arranged on the channel 5 . The head end of the locking connecting rod 2 is connected with the driving element 1, and the tail end is provided with a lock cylinder (not shown in the figure) which can extend into the mold 3 and be clamped with it. The lock column is a conical column, or a triangular conical column, or a wedge-shaped column, or a trapezoidal column. The lock column of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com