Improvement on transmission mechanism of silk printing machine

A technology of transmission mechanism and screen printing machine, which is applied in the direction of screen printing machine, printing machine, rotary printing machine, etc. It can solve the problems of insufficient transmission stability, insufficient support force, large printing color difference, etc., and achieve fast printing speed and stable support force , The effect of small printing color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in combination with specific embodiments.

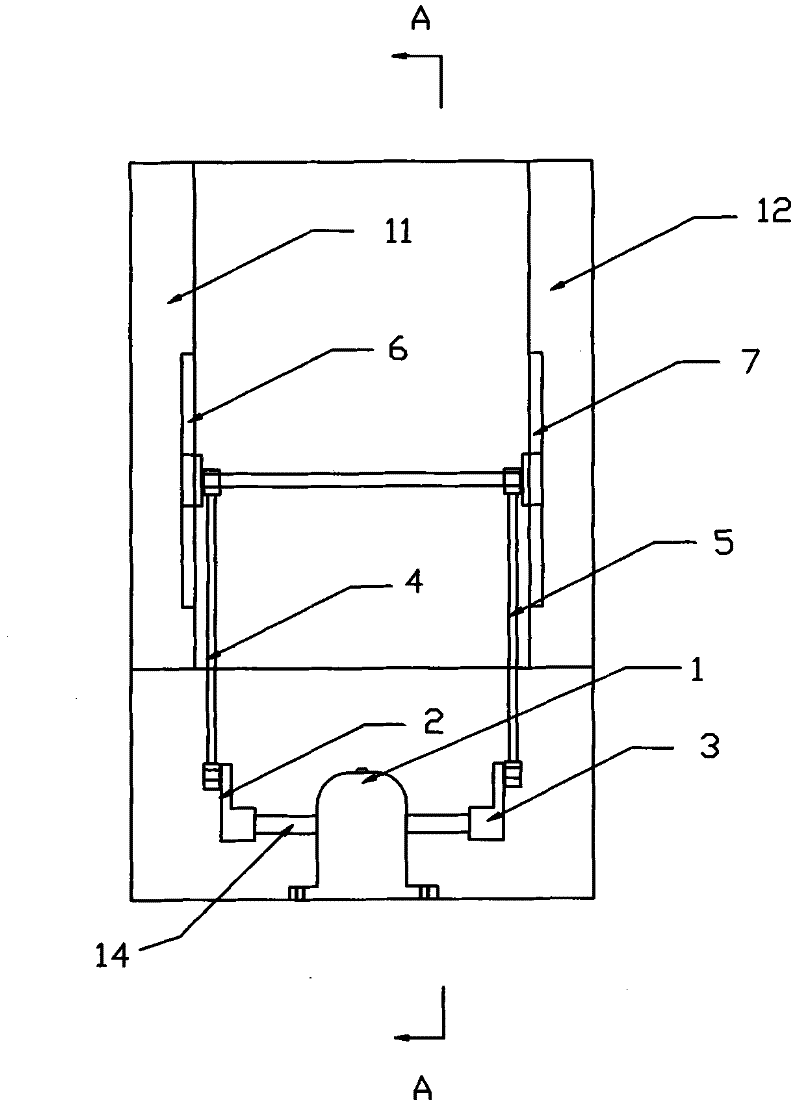

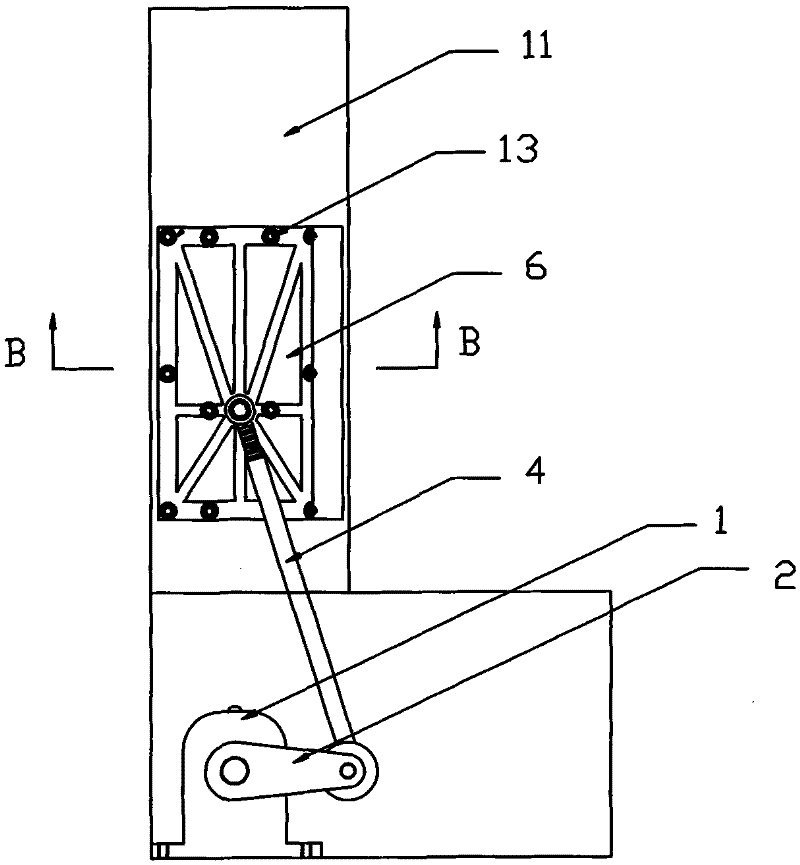

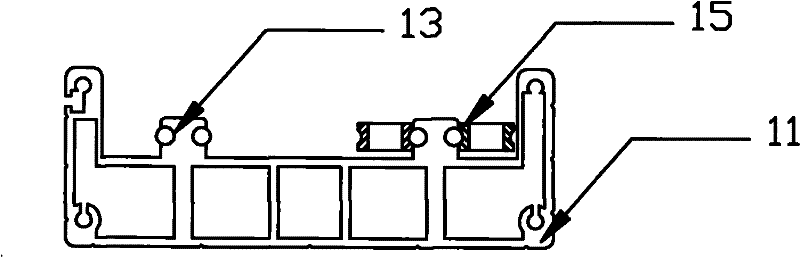

[0017] see Figure 1-4 As shown, the improvement of the transmission mechanism of a screen printing machine provided by the present invention includes a reducer 1, a rocker arm, a support rod, a slide plate and a fixed frame. There are two groups of the rocker arm, support rod and slide plate, and the reducer The output shaft 14 of 1 has two left and right output ends, and the left rocker arm 2 and the right rocker arm 3 are respectively installed on the left and right two output ends, and the other ends of the left rocker arm 2 and the right rocker arm 3 are respectively connected to the left support rod 4 and the right Support bar 5, left support bar 4 and right support bar 5 other ends are hinged on left slide plate 6 and right slide plate 7, fixed frame 1 comprises left frame body 11 and right frame body 12, and left frame body 11 or right frame body 12 A gui...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap