Method for weaving hollow permeable double-layer cloth

A hollow, double-layer technology, applied to textiles, papermaking, fabrics, textiles, etc., can solve the problems of no ventilation function, low production cost, no ventilation layer, etc., and achieve the effect of various patterns, easy cutting, and easy drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

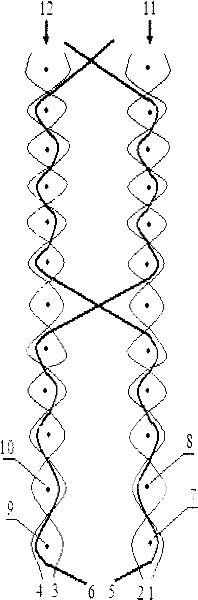

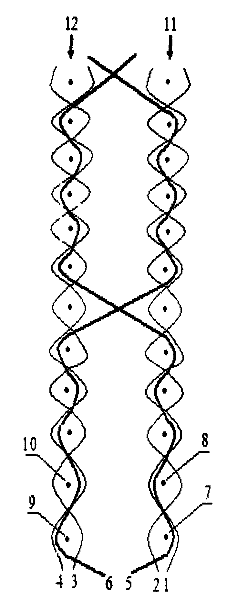

[0017] figure 1 It is a warp cross-sectional view of the connection state of warp yarn, weft yarn and pile warp according to the embodiment of the present invention;

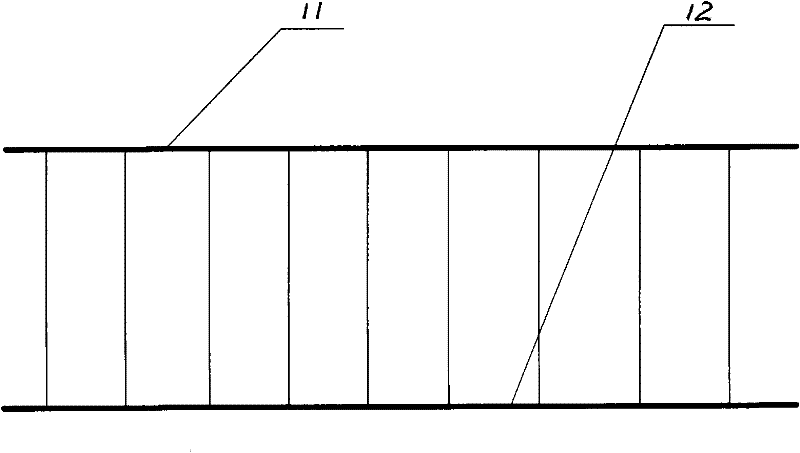

[0018] figure 2 It is a schematic structural diagram of an embodiment of the present invention.

[0019] figure 1 Middle: 1, 2-upper warp, 3, 4-lower warp, 5, 6-cashmere warp, 7, 8-upper weft, 9, 10-lower weft, 11-upper fabric, 12- -Lower fabric;

[0020] figure 2 Middle: 11—upper cloth, 12—lower cloth.

[0021] The weaving method of the hollow and breathable double-layer fabric is described in detail below with reference to the drawings:

[0022] (1) Raw material selection: Choose 450D high-strength polyester filaments with high strength, good abrasion resistance and corrosion resistance, and certain flame retardant and antistatic properties as upper warp yarns 1, 2 and lower warp yarns 3, 4 and upper For the weft yarns 7, 8 and the bottom weft yarns 9, 10, 350D polyamide filaments with better wear resistance, fati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com