Super-large span variable section double-layer and three-layer prestressed rib beam type net rack and making method

A variable cross-section and prestressing technology, applied in the direction of construction and building structure, can solve the problems of unreachable and expensive engineering, and achieve the effect of reducing the amount of structural steel, economical design requirements, and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

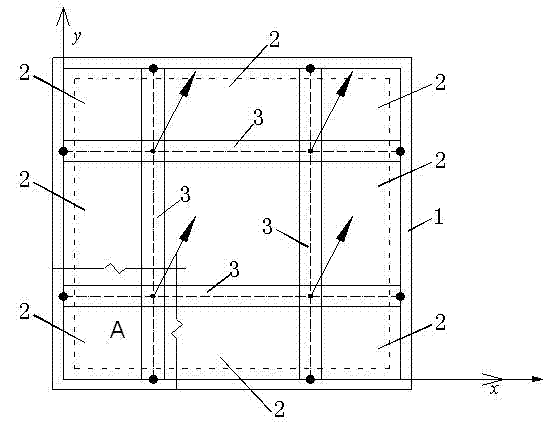

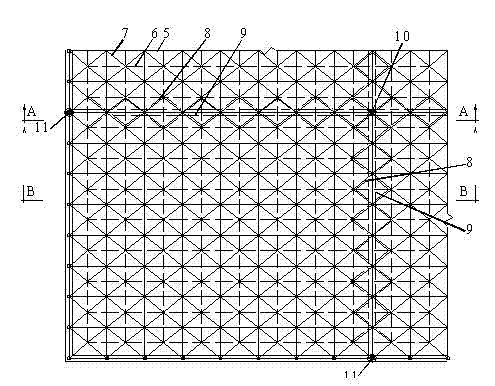

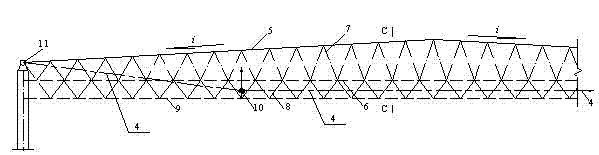

[0029] Example 1. Such as figure 1 As shown, it includes grid frame 1. Grid frame 1 is composed of double-layer square pyramid truss 2. Double-layer square pyramid truss 1 is composed of upper chord 5, lower chord 6 and diagonal web bar 7. Upper chord 5 passes through diagonal web bar 7. Connect with lower string 6. The double-layer upright quadrangular pyramid truss 2 has a variable cross-section along the x direction, the height of the cross-section is large in the middle, and the two ends are small; along the y-direction, the upper chord 5 and lower chord 6 of each double-layer upright quadrangular pyramid truss 2 are parallel to each other. About 1 / 3 of each side of the grid 1 is a three-layer square pyramid truss 3 along the x direction and the y direction; the upper chord of the three-layer square pyramid truss 3 is the lower chord 6 of the double-layer square pyramid truss 2 , and connected with its lower chord 9 through the lower diagonal 8 . Prestressed steel ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com