System and method for offline secondary detection and checking of machine detected data of large-piece checker

A technology of machine inspection data and secondary inspection, which is applied to coin inspection, instruments, and processing coins or valuable banknotes, etc. It can solve the problem of a large number of waste by mistake, achieve convenient operation, reduce the risk of manual waste leakage, and avoid information sharing The effect of conflict

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

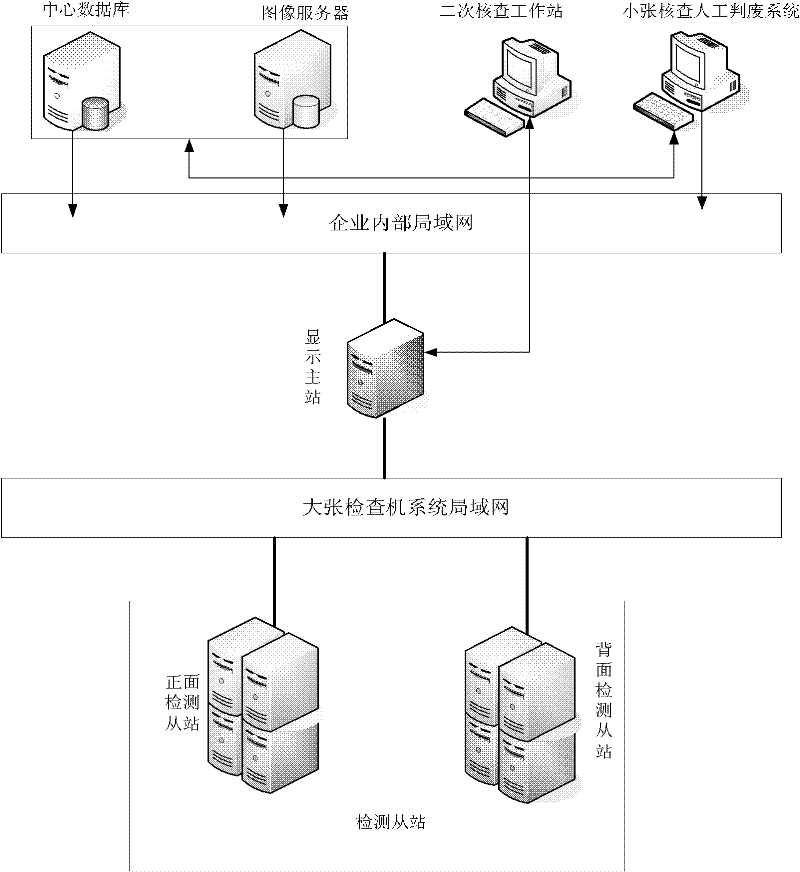

[0048] The whole system involves the internal LAN of the enterprise and the local area network of the Dazhang inspection machine system; it includes the following equipment center database, image server, secondary verification workstation, Xiaozhang verification manual waste judgment system, display master station and detection slave station; the detection slave station includes the front The detection slave station and the rear detection slave station, these devices are interconnected through the industrial field network.

[0049] 1. The data (defect information and defect image) of the secondary verification workstation comes from the database of the display master station;

[0050] 2. The secondary verification workstation will temporarily access the data during operation and perform verification operations. After the verification is completed, the result flag will be set for the car number table in the DZVS database of the main station according to the verification result;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com