LED microarray packaging structure and manufacturing method thereof

A technology of packaging structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of cumbersome process, small level, and inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

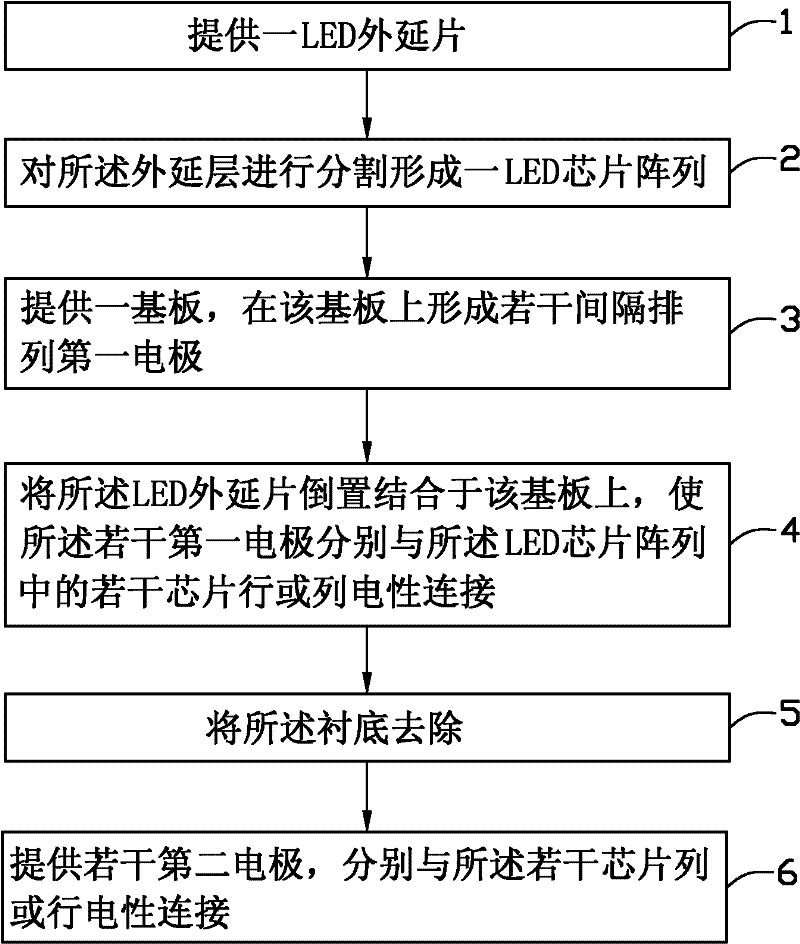

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

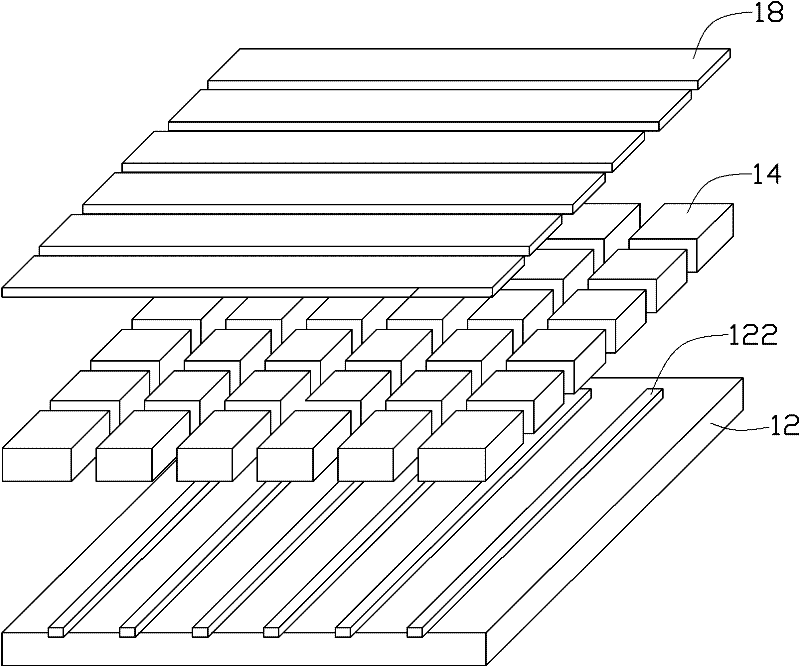

[0034] see figure 1 and Figure 11 One embodiment of the present invention provides an LED microarray packaging structure 100, which includes a substrate 12, a plurality of spaced first electrodes 122 disposed on the substrate 12, a plurality of LED chips 14 arranged in an array, and a plurality of second electrodes .

[0035] The substrate 12 is square in this embodiment, and its material can be copper or other suitable metals or metal alloys, such as aluminum or aluminum alloy, or other suitable non-metals, such as silicon and ceramics. The first electrodes 122 are disposed on the substrate 12 and insulated from the substrate 12 , and the first electrodes 122 are arranged at intervals corresponding to each row of the LED chip array 14 .

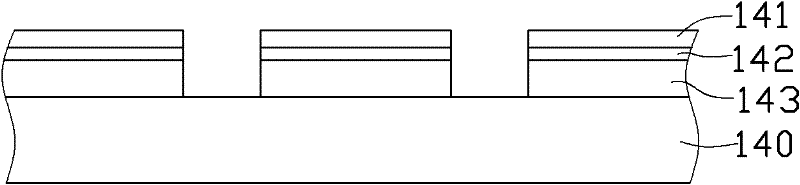

[0036] The LED chip 14 is a blue gallium nitride (GaN) LED chip in this embodiment. Of course, the L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com