Front axle bracket for a motor vehicle and method for the production thereof

A technology for motor vehicles and front axles, applied to vehicle parts, substructure, transportation and packaging, etc., can solve the problems of high overall weight, high material cost, etc., and achieve the effect of less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

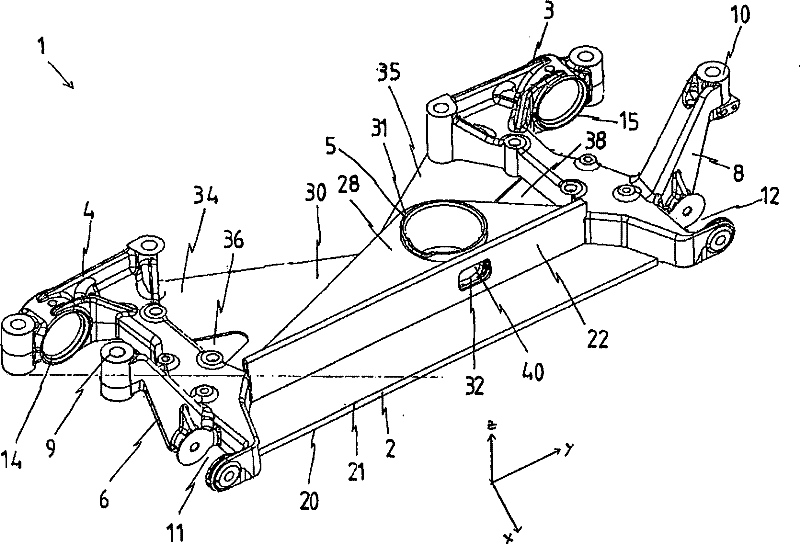

[0020] figure 1 The front axle carrier 1 shown in is produced from light metal, in particular aluminum or an aluminum alloy, and has a transverse beam 2 and two side gussets 3 and 4 . The pendulum support bearing 5 is preferably configured in the transverse beam 2 as a substantially vertically extending cylindrical bearing bearing.

[0021] On the corner brackets 3, 4, upwardly extending arms 6, 8 are configured with supports 9, 10 for fixing the front axle carrier 1 on the vehicle, and for the wheel guide suspension coupling of the vehicle. Front bearing mounts 11, 12 for the rod, and rear bearing mounts 14, 15 for the wheel bearing mounts. The side angle brackets 3 , 4 are constructed as cast parts and, if applicable, correspondingly finished to form the individual supports.

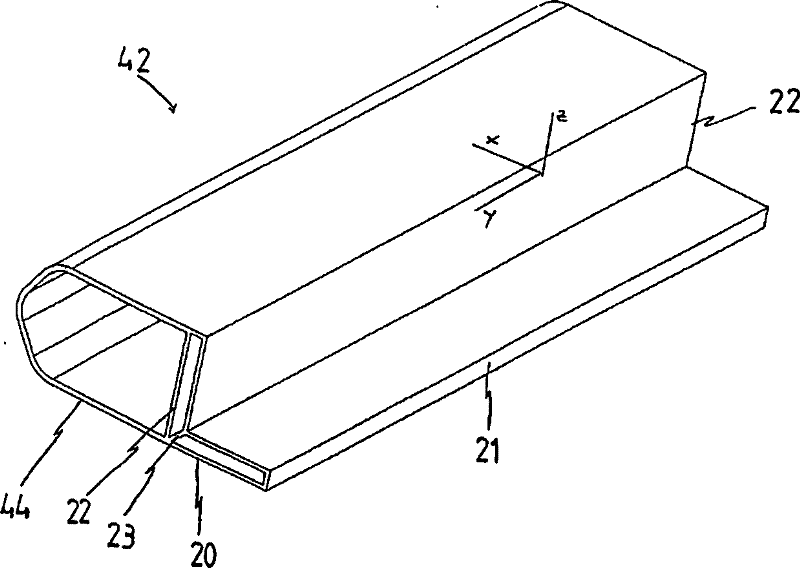

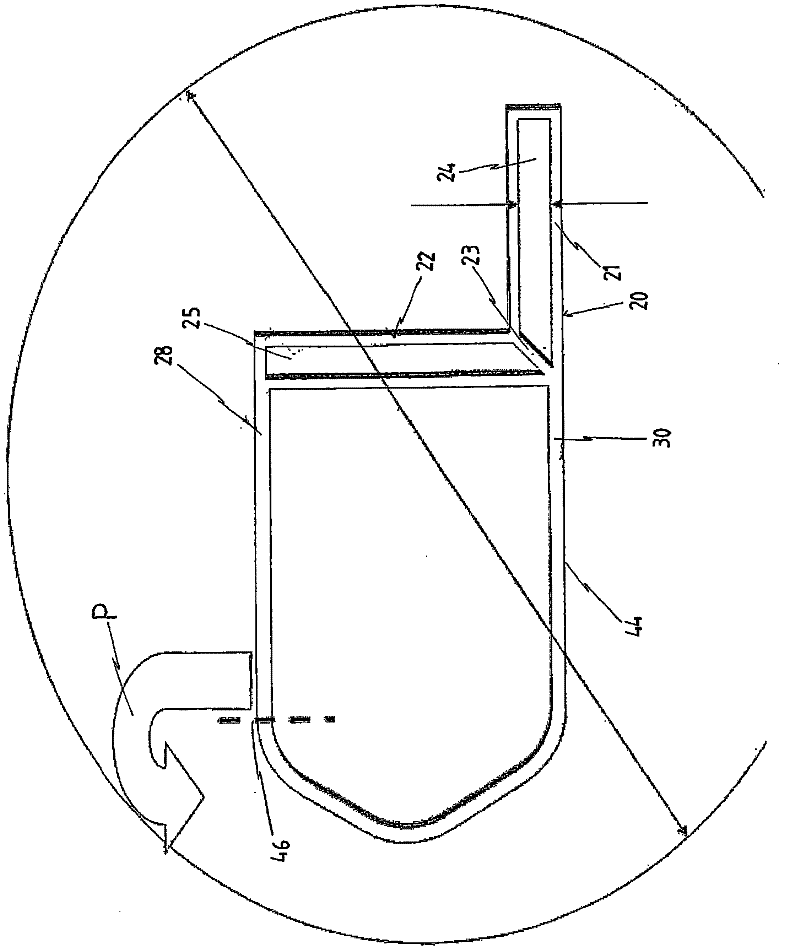

[0022] The transverse beam 2 according to the invention has a front double-walled area 20 which is formed by connecting a front horizontally extending web 21 of the double wall and a vertically exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com