Mount for installing structure, and solar cell system

A technology of solar cells and structures, applied in solar heating systems, solar thermal power generation, solar thermal energy, etc., can solve the problems of corrosion of metal parts, moisture of metal parts, increase of assembly hours, etc., and achieve the effect of improving load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

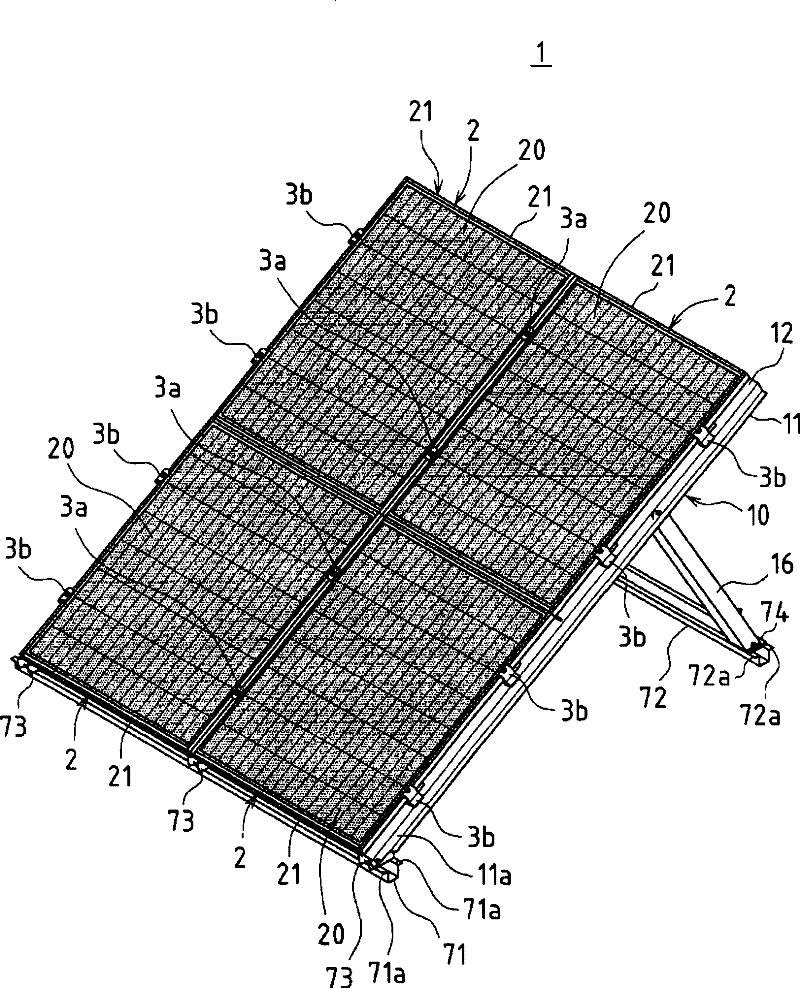

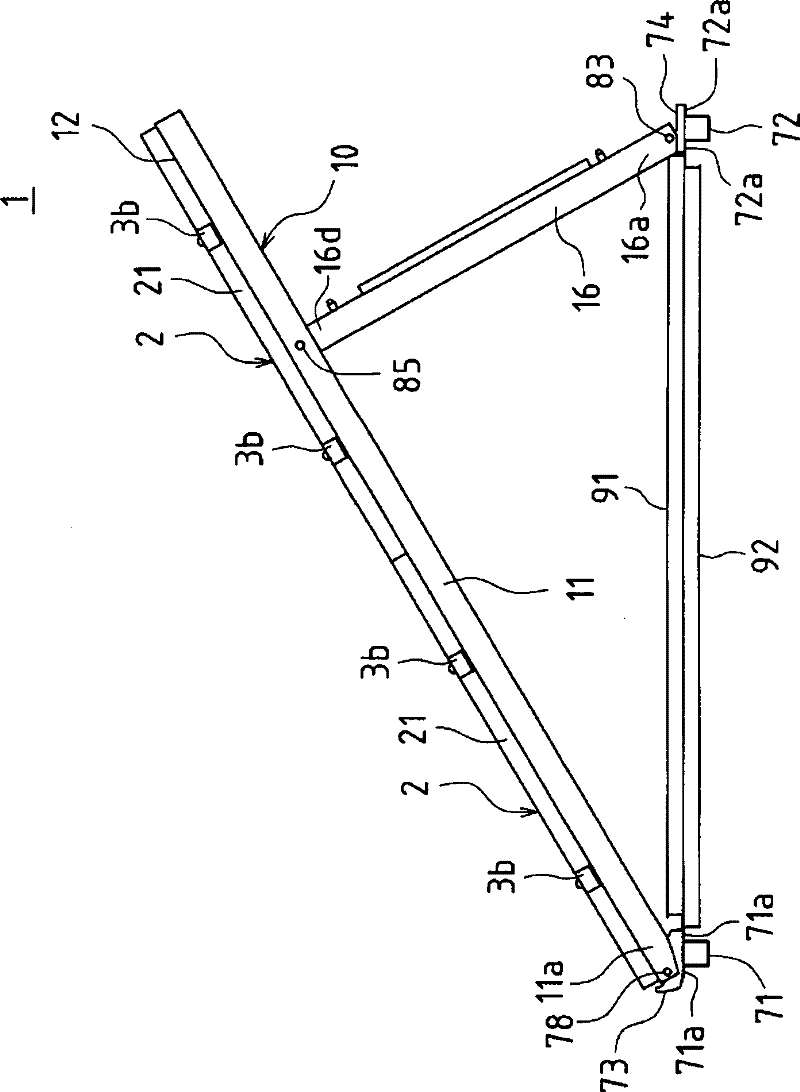

[0092] figure 1 It is a perspective view showing a solar cell system according to an embodiment using the structure mounting bracket of the present invention. also, figure 2 It is a side view showing a bracket provided for the structure of this embodiment.

[0093] Such as figure 1 As shown, in the solar battery system 1, two base rails 71, 72 are fixed to a flat roof, etc., three structure installation supports 10 are arranged side by side on each base rail 71, 72, and each structure installation support 10 is loaded Place and fix four solar battery modules 2 .

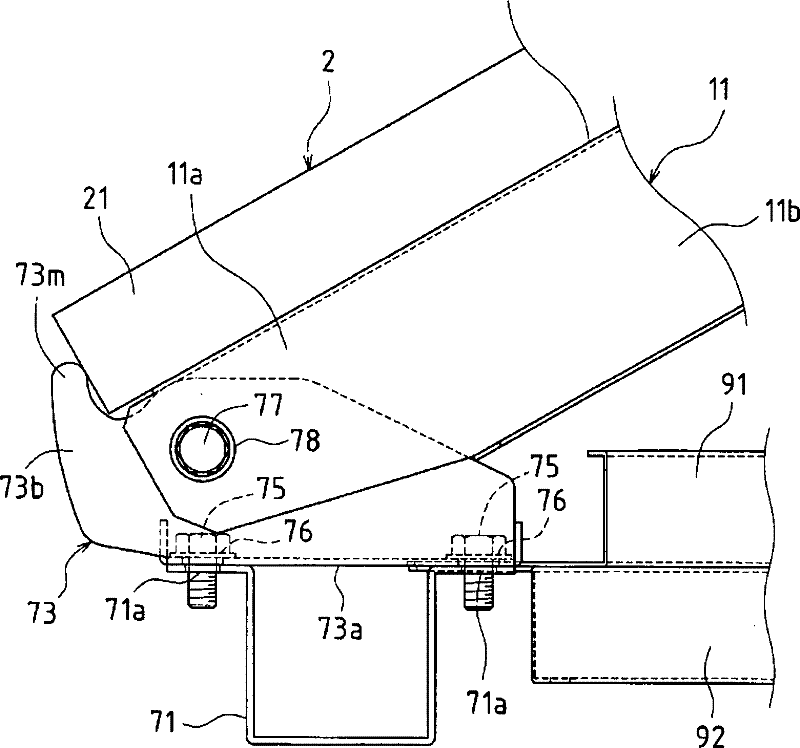

[0094] Each base rail 71, 72 has a hat-shaped cross-sectional shape, and the hat-shaped opening side faces upward. The flange-shaped flat plate portions 71a, 72a on the side are positioned on the same two-dimensional plane, and the flange-shaped flat plate portions 71a, 72a of the respective ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap