Method and apparatus for making liquid flexographic printing elements

An equipment and liquid technology, which is used in the field of manufacturing liquid flexographic printing components and equipment, can solve the problems of difficulty in the thickness and uniformity of the bottom layer, and difficulty in exposure control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] This invention generally relates to improvements in methods and apparatus for making plates from liquid photopolymer plates.

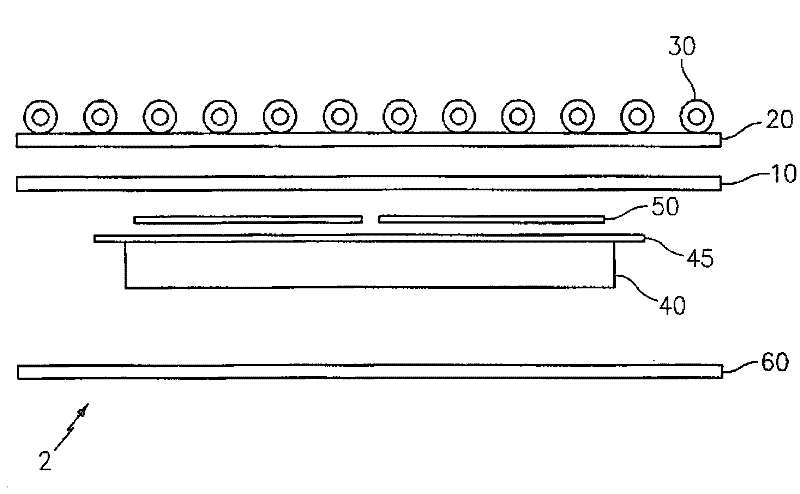

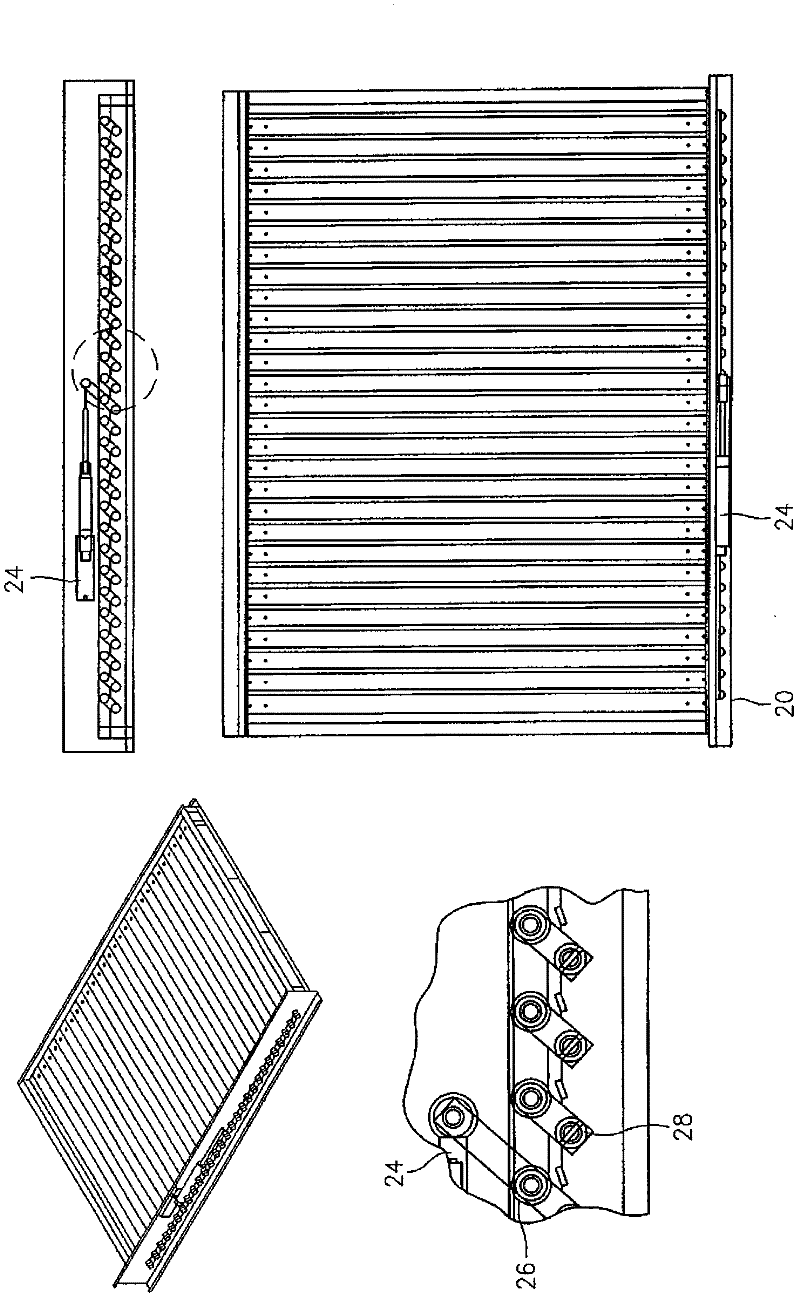

[0045] In one embodiment, such as figure 1 As shown, the present invention generally relates to a platemaking system 2 for printing a blank from a liquid photopolymer to make a flexographic relief image printing plate, the system comprising:

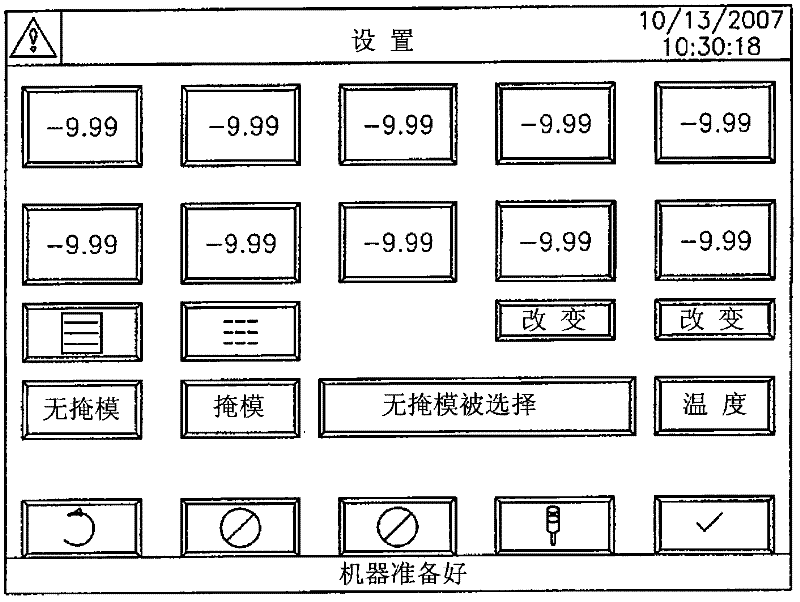

[0046] a) One or more devices for performing the step of manufacturing a relief image printing plate from a liquid photopolymer printing blank, wherein the one or more devices are selected from the group consisting of devices for setting relief image printing A glass setting device of the desired specification for the plate; a device for controlling UV exposure of a printing plate during an imagewise exposure step; a device for performing mask exposure of said printing plate; in combination with one or more of the above devices body;

[0047] b) a microcontroller operatively connected to one or more devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com