Method for manufacturing rough blank of attapulgite environment-friendly teacup jacket

A production method and attapulgite technology, which is applied to clay products, manufacturing tools, auxiliary molding equipment, etc., can solve problems such as unsanitary, burns, and poor smooth feel of plastic coats, and achieve the effects of protecting the environment and improving health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention will be further described:

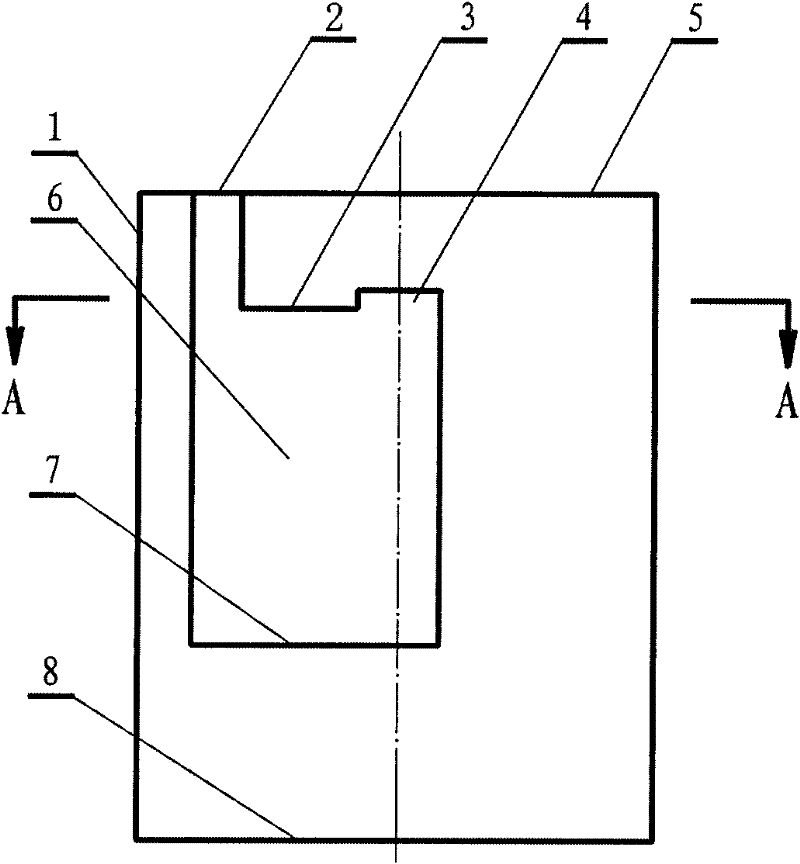

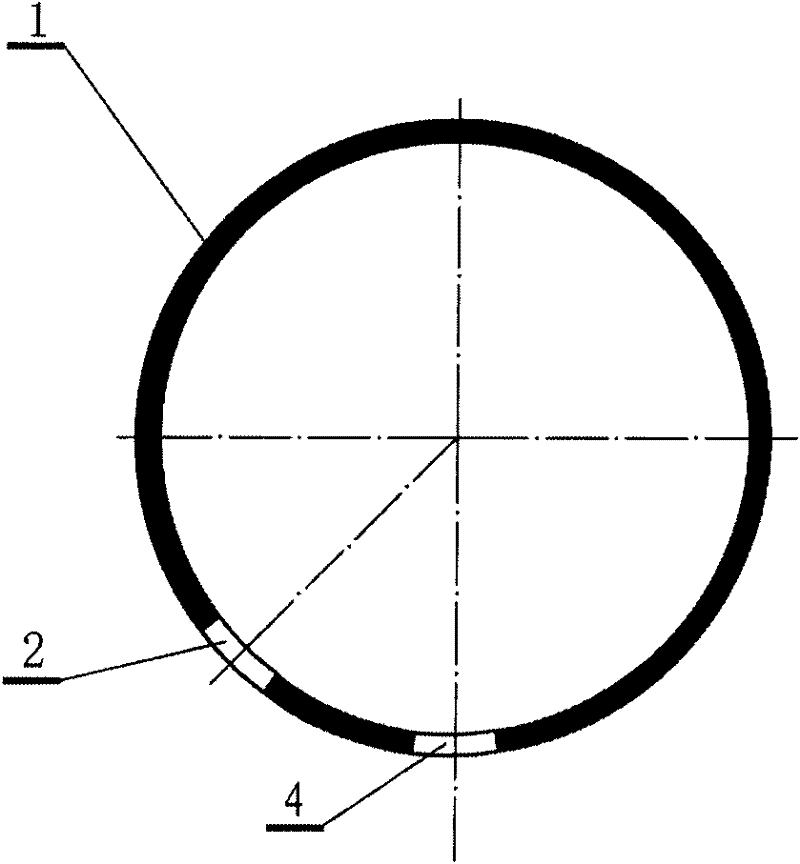

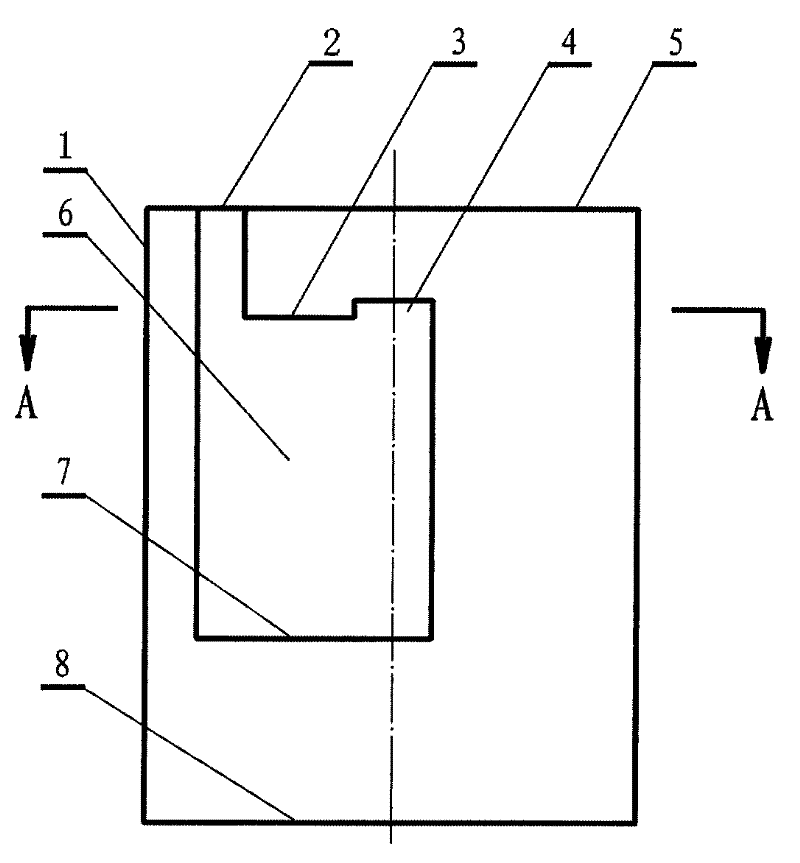

[0029] 1. The method for making the rough blank of the attapulgite teacup environmental protection jacket: (1) use the attapulgite clay with the function of purifying air to make the rough blank of the attapulgite teacup environmental protection jacket. The green body is a cylindrical shell 1, The height of the cylindrical shell 1 is controlled at 150 mm, and the diameter is controlled at 100 mm. There is a sealed bottom plate 8 at the bottom of the cylindrical shell 1, and the upper part 5 of the cylindrical shell is open. The front center line of body 1 is 45 degrees to the left, and an L-shaped groove 6 is cut from top to bottom and then to the right. The width of the plane of the entrance 2 of the L-shaped groove is controlled at 20 mm, and the distance between the upper plane 3 and the inner surface of the L-shaped groove is L The plane of the entrance 2 of the L-shaped groove i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com