Tray of automatic feeding device

An automatic feeding and tray technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems such as the quality of the shaft inserted into the motor bottom plate of the transformer, the insertion depths are different, and the shaft is loose, etc. Reasonable structural design, reducing labor and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in further detail below in conjunction with the accompanying drawings.

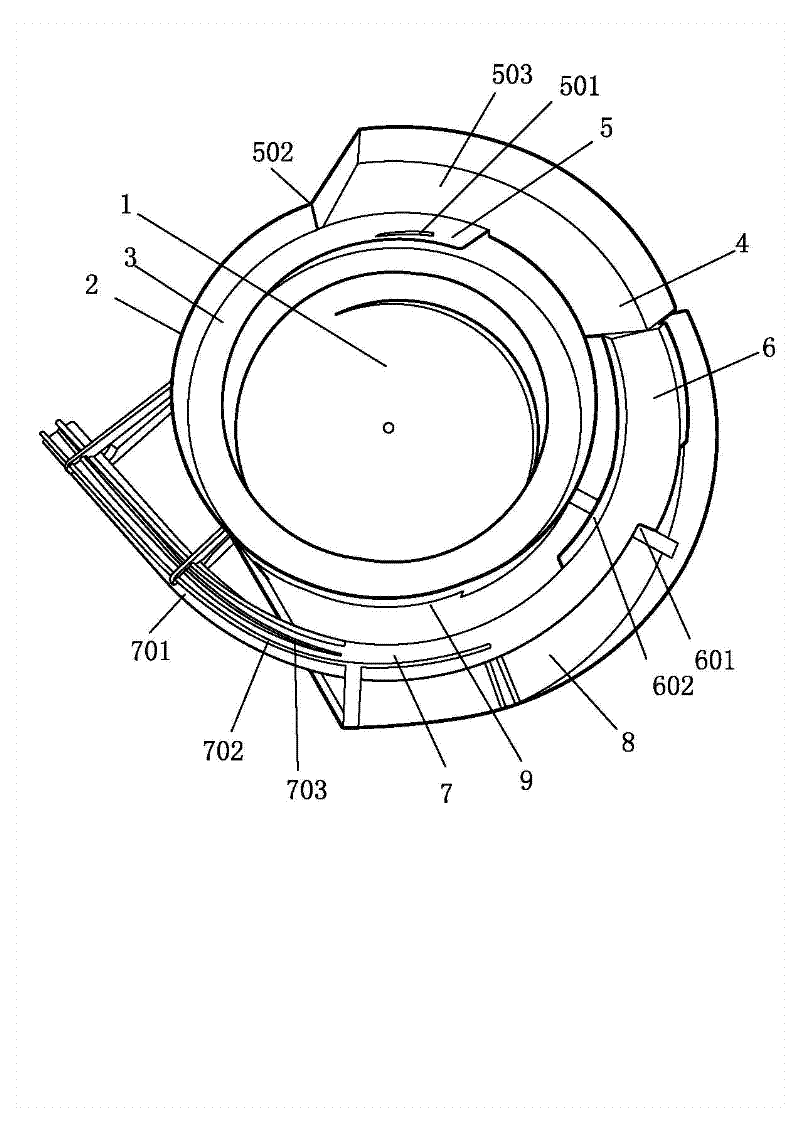

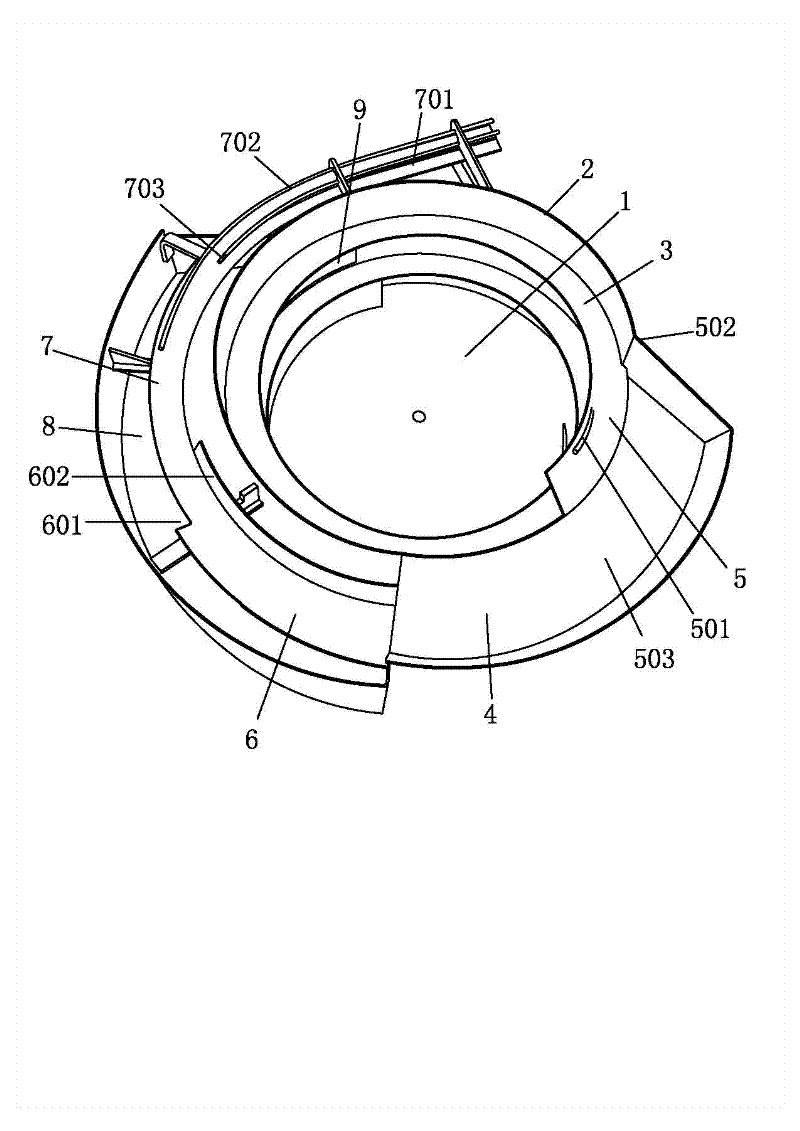

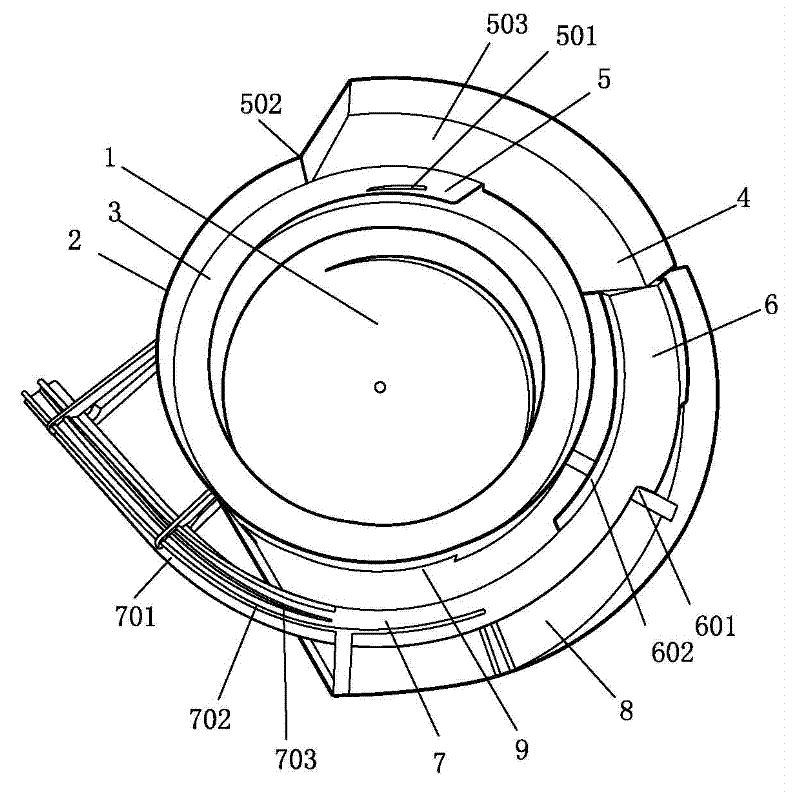

[0016] Such as Figure 1 to Figure 2 As shown, a material tray of an automatic feeding device includes a disk surface 1 and a side wall 2 surrounding the disk surface 1. The disk surface 1 is a conical surface with a convex center, and the spare parts move around the periphery of the disk surface 1. The rising feeding track 3, the feeding end of the feeding track 3 is located at the lower part of the disk surface 1, the spare parts enter the feeding track 3 from the low point, and the outer side of the side wall 2 is provided with a monolithic track 4, the feeding track 3 The discharge end of the material is connected with the monolithic track 4, and the monolithic track 4 at least includes a along section 5, a sorting section 6 and a sorting section 7. The outer periphery of the monolith track 4 is provided with a collecting groove 8, which is integrated with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com