Selective catalytic reduction converter of diesel engine for automobile

A technology for catalytic converters and diesel engines, used in machines/engines, chemical instruments and methods, mechanical equipment, etc., can solve problems such as NH3 leakage, increase in exhaust pressure loss, and impact on engine power, and achieve sufficient reaction and pressure loss. Small, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

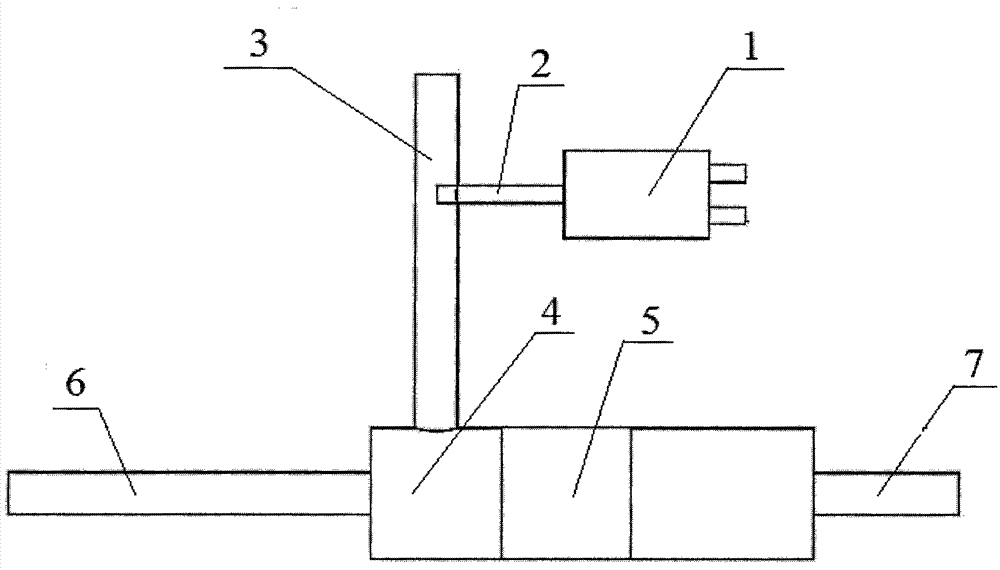

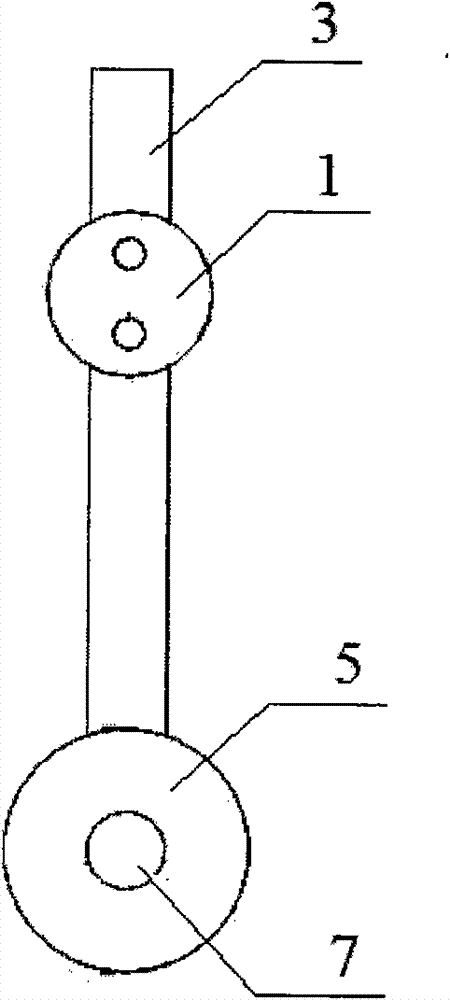

[0020] A selective reduction catalytic converter for a vehicle diesel engine, its structure is as follows Figure 1-2 As shown, the catalytic converter is composed of a urea controller 1, an injection device 2, an atomizer 3, a mixer 4, a reformer 5, an exhaust gas inlet 6 and a mixed gas outlet 7. The front end of the urea controller 1 is provided with a nozzle Through the nozzle hole, urea can be added to the catalytic converter. The injection device 2 is connected to the urea controller 1 and the atomizer 3. The injection device 2 is provided with 4 uniformly distributed radial nozzle holes with a diameter of 1mm. spray hole, the urea solution can enter the atomizer 3 for atomization, the mixer 4 is arranged at the bottom of the atomizer 3, the tail gas inlet 5 and the reformer 6 are respectively arranged at the two ends of the mixer 4, and the mixed gas outlet 7 is arranged At the front end of the reformer 6.

[0021] After the atomized urea aqueous solution (32.5% urea m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com